200W - 1000W

Precise Cleaning

Pulsed Laser Cleaning Machine

Pulsed Fiber Laser Cleaning Machine

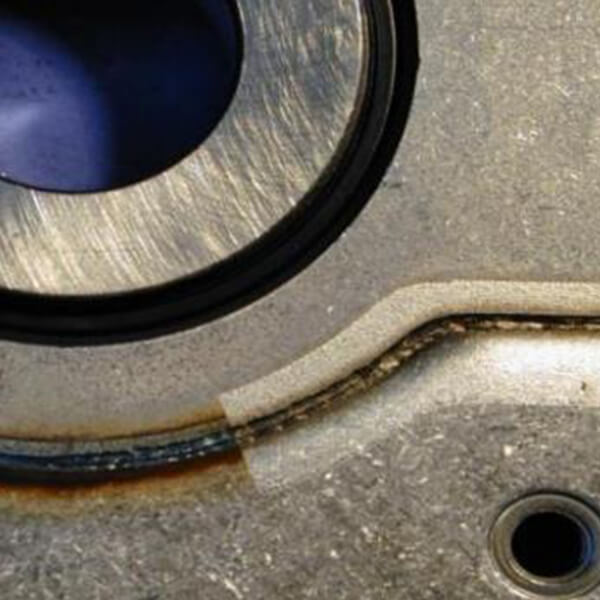

MORN pulsed fiber laser cleaning equipment enables you to effortlessly get rid of the toughest rust, dust, oxides, oil and other contamination as well as paint, coating from metal, plastic, ceramics, glass, stone or concrete. Cleaning with pulsed laser is best for precise cleaning such as mold cleaning. No damage to the substrate.

You will conveniently handle narrow spaces and curved surface that cannot be reached with traditional cleaning tools.

With a mobile and compact body, you can clean wherever you need or couple it into production or an assembly line to achieve auto cleaning.

Features

Precise and targeted area cleaning and excellent surface cleanliness

Non-contact cleaning with no damage to parent material

No cleaning agents required, safe and environmental protection

Compact and easy to use

Interested in product catalog, pricing or videos?

Just leave a message or chat with our enthusiastic sales consultant.

Parameters

| Model | MT-CL200 MT-CL500 MT-CL1000 |

| Power | 200W 300W 500W 1000W |

| Supply voltage | Single-phase 220V ± 10%, 50 / 60Hz AC |

| Work environment humidity | ≤80% |

| Fiber length | 5m-10m (customizable) |

| Power Adjustable Range | 10-100mm (adjustable) |

| Laser average power | ≥200W |

| Power adjustment range (%) | 10-100(Adjustable gradient) |

| Focus spot diameter | 0.08mm |

| Center wavelength | 1064nm – 1080nm |

| Peak power maximum | 10kw |

| cooling | Air cooling/water cooling |

| Type of manipulator | Manual / Based on galvanometric laser scanner |

| Manipulator weight | 2.75KG |

| Size | 1180mm×730mm×1280mm |

| Machine Weight | 200KG |

Problems in traditional industrial cleaning

Mechanical friction cleaning

High cleanliness, but easy to damage the substrate

Chemical corrosion cleaning

Stress-free cleaning, but serious cleaning

Liquid solid spray cleaning

High flexibility, but high cost. Complicated waste liquid treatment is required

High Frequency Ultrasonic cleaning

Good cleaning effect but limited cleaning size

Laser Cleaning Advantages

Laser cleaning – eco-friendly technology, wider application

Laser cleaning can be used not only to clean organic contaminants, but also to clean inorganic materials, including metal corrosion, metal particles, dust, etc. Its applications include: rust removal, paint stripping, oil stains removal, cultural relics restoration, degumming, decoating, deplating. It has no challenge at all to deal with thick rust and paint layer, tough oil stains as well as surface roughening, weld cleaning and other processes. Additionally, without chemical consumables and solution involved, it saves the trouble to deal with waste and is more environment-friendly.

High adaptability, long service life

When designing and configuring this tool, we take practicality and quality as priority. By adopting a customizable length of fiber optic cable with a hand-guided manipulator, the laser cleaning equipment has a high tolerance range for the smoothness of the surface of the workpiece and the processing height. It can be used not only in a stable industrial environment, but also in complex outdoor places, such as rail rust removal, fresco cleaning, bronze cleaning. Furthermore, it can work with a robotic arm to realize auto cleaning. To ensure the laser quality and in consideration of cost-effectiveness, we equip the cleaner with a top-notch laser source, which has stable light emission and service life as long as 100,000h.

Higher efficiency & precision, better cleanliness

A pulsed fiber laser with a master oscillator power amplifier (MOPA) structure offers the advantage of precise heat control, which is a critical point during the cleaning process. It improves the cleaning efficiency while ensuring the cleaning effect and precision. What’s more, the tool is easy to operate, no need to disassemble, also, the cost of use is correspondingly low.