While fiber laser marking and engraving are well-established processes, innovations and investments in the sector are continuing to push performance boundaries. With more industries bringing fiber laser marking in-house, faster systems with higher wattage and bigger bed sizes are in high demand.

With brand protection becoming an ever-present concern, marking of date codes, serial numbers and other identifying data on vital components helps protect manufacturers from the liability of counterfeit parts and offers quality assurance to customers. That’s a vital field where fiber laser engravers are extremely welcomed by brand owners. For example, FDA-required unique device identification (UDI) codes track and trace medical devices. Another key advantage of laser marking is on-the-fly identification of parts in constant motion. Inks can’t always fulfill that need, and can also create clogging problems and, as a consumable item, must be managed. Fiber lasers eliminate those issues.

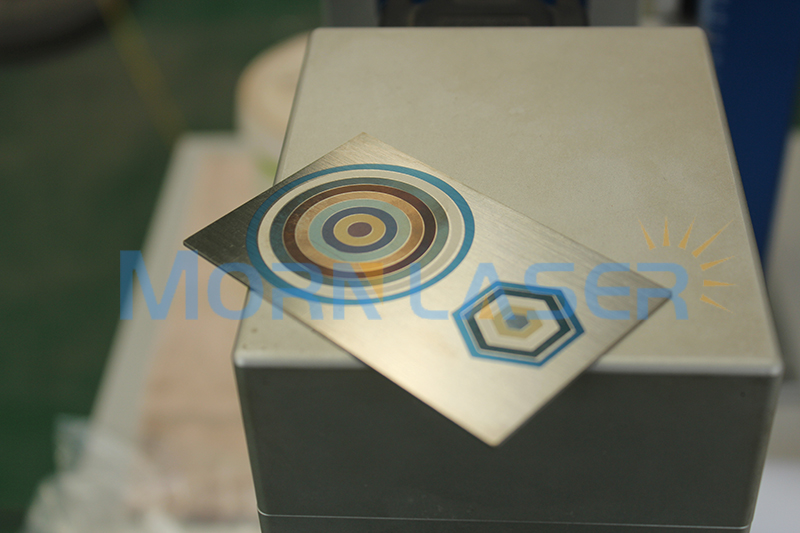

Other applications could include using different color markings to identify components like dental drill bits. Or, a business might need different colors for its logos to represent different divisions. Unlocking the secret of marking in color by carefully controlling beam parameters has also facilitated fiber lasers’ ability. MOPA fiber lasers are competent to mark colors on stainless steel to quickly mark a growing range of challenging materials. Just contact us to learn more about the versatility of MOPA fiber laser.

More companies than ever before are investing in fiber lasers. While the automotive industry was undoubtedly the early adopter, this relatively new solution is being snapped up across the board and when you consider the advantages, it’s easy to see why.

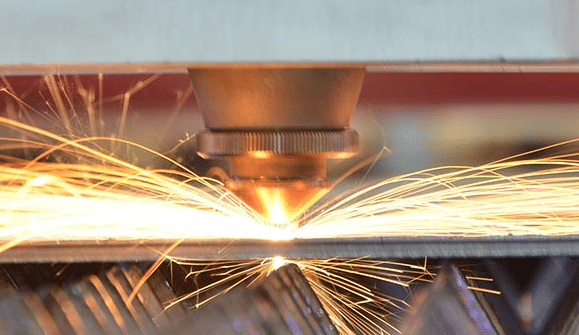

1. Extra speed

The sheer speed of fiber laser markers makes them the first choice for customers looking to increase efficiency. They’re the fastest laser marking technology at their wavelength, delivering marking times of less than one second for some applications.

2. Energy efficiency

Despite being faster, fiber lasers are energy-efficient compared to the alternatives. Not only does this result in reduced power consumption, but it also helps make the system simpler, smaller, and more reliable. Fiber laser technology uses basic air cooling rather than an additional chiller unit, which would be costly and cumbersome. With many businesses finding both cash and floor space in short supply, compact and efficient fiber laser marking solutions are proving to be the right fit.

3. Longer life

Fiber lasers have an expected life of around 100,000 hours, which means about 45 years’ use. Saying that, will companies still be using the same fiber laser in 45 years? I doubt it! Regardless, this option does deliver an impressive return on investment.

4. Laser power

Because of the duration of power delivery by the technology, fiber laser marking solutions are ideal for deep marking. Rather than delivering a continuous stream of energy, fiber lasers deliver extended pulses. They deliver energy over a longer period of time, which is ideal for marking deep, durable marks. A good practical example is in manufacturing automotive brake systems.

To learn more about the latest in laser marking technology, please contact us today. The world of laser technology is constantly changing and new innovations are being introduced every day. We would like to share that world with you.