Introduction to MOPA fiber laser color marking

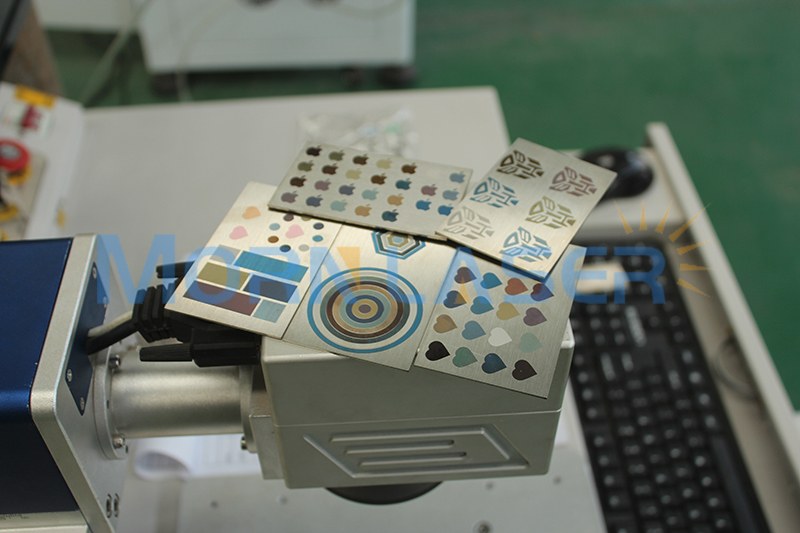

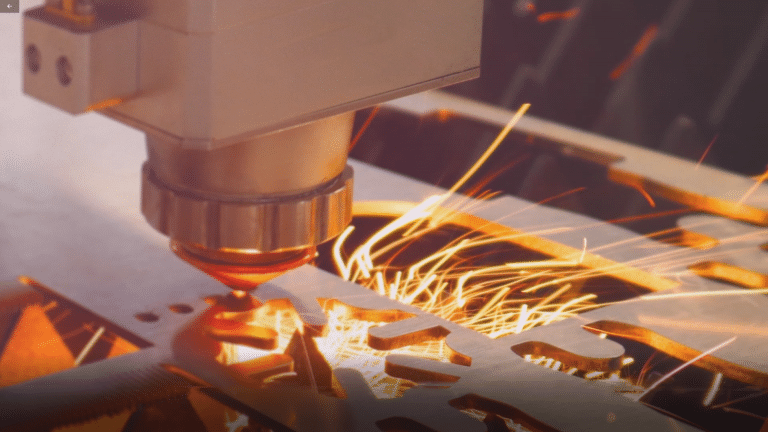

The use of fiber laser color marking is not a particularly new technique as it has been recognized for over 10 years. This technique was originally identified as a viable process for use on craft metal work and jewelry. With a decade of rapid development and innovation, color marking by MOPA fiber laser has been maturely employed in both industrial and commercial activities.

There is now a greater interest in this process as manufacturers of consumer goods are looking for new techniques and finishes to provide product differentiation. This application insight looks at a variety of materials that are color mark-able including titanium and stainless steel, and explores the benefits and parameters of the Pulsed Fiber Laser in relation to this application area.

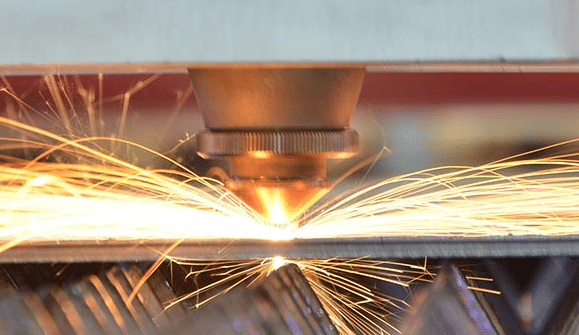

MOPA fiber lasers utilize semiconductor diodes as the pumping mechanism and a doped fiber optic cable as the gain medium. For these fiber lasers, the doped fiber optic also serves as the resonator. MOPA fiber lasers are much more reliable and efficient than previous laser technologies. With these laser systems, you know you are getting the best technology on the market.

MOPA fiber laser marking application

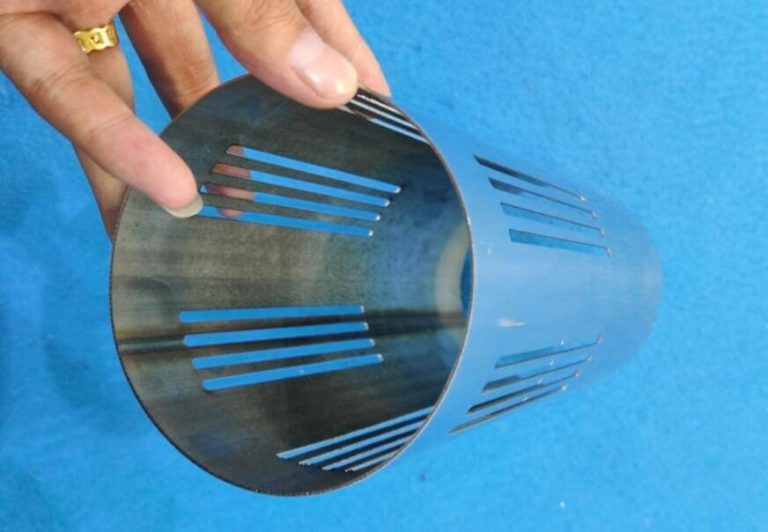

There are a wide range of materials that are known to be color mark-able including: stainless steel, titanium, chrome plate and transition metals. The specific material grades and surface finishes can have an impact on the marking process and the thickness of the material.

Stainless steel product

s are often marked with numbers, bar codes/two-dimensional code, patterns, etc., to meet the product traceability or aesthetic needs. Laser marking is green, efficient and flexible, and can be permanently retained. Laser color marking for stainless steel has provided a new and efficient solution which also allows you to mark, etch or engrave on a wider variety of surfaces.

At MORN, we strive to continuously provide our customers with the most innovative and high-quality laser marking, engraving and etching technology available. This means that each of our laser marking systems comes equipped with the latest MOPA technology.

With our MOPA laser marking machines, you have maximum flexibility and better pulse duration control no matter the project. Our technology allows you to utilize selectable wave forms and an expansive frequency range, offering greater peak power at high frequencies.

For more information, please visit our website to find a suitable laser solution for your business, or leave a message below to get answers for your laser questions.