The increasing awareness of environmental protection has brought enormous challenges to the development of cleaning industry around the world. Responding to this situation, various cleaning technologies that are conducive to environmental protection have emerged, among which laser cleaning machine is becoming more and more popular for industrial sectors.

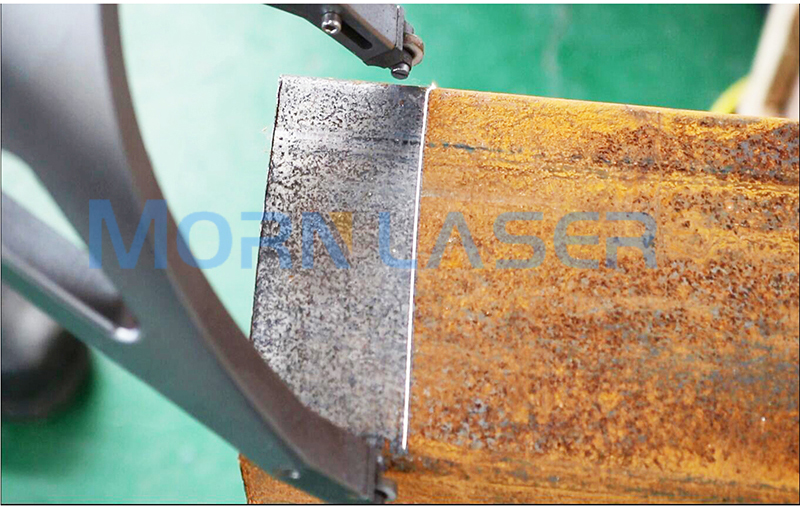

The so-called laser cleaning technology refers to the use of a high-energy laser beam to illuminate the surface of the workpiece, so that the dirt, rust or coating on the surfaces is instantaneously evaporated or peeled off. Laser cleaning is a new technology based on the interaction between laser and materials. Unlike traditional mechanical cleaning, chemical cleaning or ultrasonic cleaning (wet cleaning process), laser cleaning machine does not require any CFC-based organic solvents that can destroy the ozone layer and damage the environment. Laser rust removal tool provides a green cleaning method with no noise, harmless to the human body and the environment.

Compared with traditional cleaning methods, laser cleaning has distinct advantages:

- It is efficient, fastand cost-effective with low heat load and mechanical load on the substrate. The whole cleaning process won’t damage the original material, only contamination or rust is removed from material surface;

- It is safe and reliableas it won’t damage the health of operators;

- It can remove various coatings of different thicknesses and ingredients;

- The cleaning process is easy to be automatically controlled.

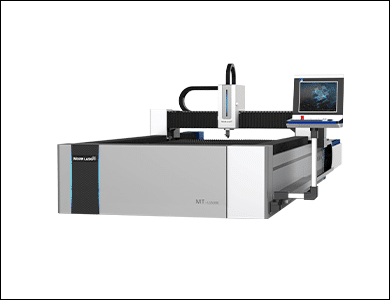

Laser cleaning machine is also called metal cleaning machine or laser rust removal machine. MORN laser cleaning machine is an advanced product in the laser system. The laser cleaner adopts a very stable and durable fiber laser source with no lamp replacement. This new Q-switched laser (also known as ultra-pulsed laser) provides an excellent tool for mold cleaning, pre-treatment of part joints, and removal of cladding which requires strong power and accuracy. The perfect laser design also provides an easy solution for a wide range of industrial applications. MORN laser cleaning machine 200W offers high efficiency, stability, and virtually maintenance-free operating systems in construction and design. The self-cooling laser source not only produce no pollutants, has no consumables, but is also easy to set up and operate.

Major applications of laser cleaning system include:

- Precision mold cleaning;

- Selective paint and welding spot removal;

- Oxides, oil, grease & production residues removal;

- Historical relics conservation.

In the next posts, we will talk more about laser cleaning technology and laser cleaning machines. You can also leave your questions below to find more information about our laser products.