Key problems brought about by traditional cleaning methods include negative environmental impact and wear on the substrate. Abrasive systems generate large amounts of waste, damaged fragile surfaces, and the use of chemical solvents produces potentially harmful vapors and liquid waste.

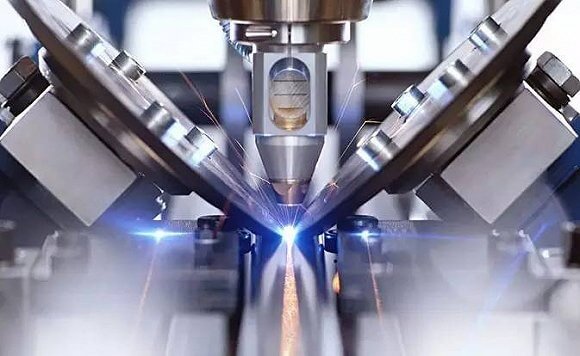

The laser cleaning machine came as a result of the need for a nonhazardous, nonabrasive cleaning method which could be used as a substitute for chemical, manual, and abrasive blasting methods.

Laser cleaning is a process that uses laser technology to remove contaminants such as grease, rust, oxides, etc. from metal and other surfaces. It allows selective removal of contaminants with minimal impact on the substrate.

Here are typical industrial application cases of laser cleaning machines.

Table of Contents

Application Case 1: Rust Removal

Product: angle steel

Material: Q235 (carbon structural steel)

Laser cleaning machine: Standard type

Cleaning efficiency: 1800mm2 / s

Cleaning effect: the rust layer is completely removed, almost no damage to the surface.

Product: Transmission gear shaft

Material: 40Cr (surface quenching and tempering + high-frequency quenching)

Laser cleaning machine: standard type

Cleaning efficiency: 1800mm2 / s

Cleaning effect: the rust layer is completely removed, almost no damage to the surface

Product: Carbon steel pipe

Material: carbon structural steel

Laser cleaning machine: standard type

Cleaning efficiency: 2000mm2 / s

Cleaning effect: the rust layer is completely removed, almost no damage to the surface

Product: Three-jaw chuck

Material: alloy steel

Laser cleaning machine: standard

Cleaning efficiency: 2000mm2 / s

Cleaning effect: the rust layer is completely removed, almost no damage to the surface

Application Case 2: Paint Removal

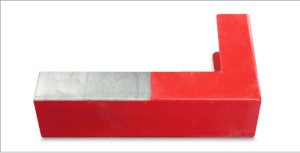

Product: Bent sheet metal

Material: carbon steel

Laser cleaning machine: standard type

Cleaning efficiency: 2200mm2 / s

Cleaning effect: the paint layer is completely removed, and almost no damage to the surface.

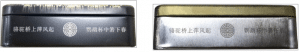

Product: Gift box

Material: cold-rolled steel plate

Laser cleaning machine: standard type

Cleaning efficiency: 1800mm2 / s

Cleaning effect: the paint layer is completely removed, and not damaged to the substrate.

Application Case 3: Welding Pre-treatment and Post-treatment

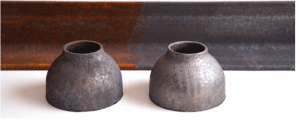

Product: Water pipe connector

Material: alloy cast iron

Laser cleaning machine: standard

Cleaning efficiency: 2200mm2 / s

Cleaning effect: the discoloration layer is completely removed, the surface is bright.

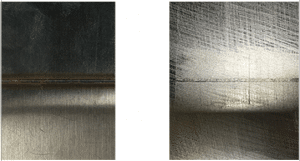

Product: Stainless steel sink

Material: SUS304

Laser cleaning machine: standard

Cleaning efficiency: 2200mm2 / s

Cleaning effect: the oxide layer is completely removed, and the surface is bright.

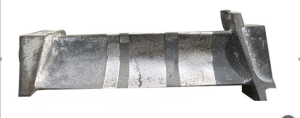

Product: Blower blade

Material: 2Cr13 (casting martensitic stainless steel)

Laser cleaning machine: standard

Cleaning efficiency: 1500mm² / s

Cleaning effect: the cast oxide layer is completely removed, the surface is bright

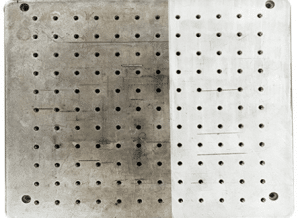

Product: Aluminum alloy plate

Material: 6033

Laser cleaning machine: standard

Cleaning efficiency: 1800mm² / s

Cleaning effect: the oxide layer is completely removed, and the surface is bright

Laser Cleaning Machine for Beginners

MORN LASRE handheld laser cleaning machine

MORN LASRE auto laser cleaning machine

Laser Cleaning Achieved by Laser Marking Machine

Laser cleaning can also be achieved by laser marking machine, check the de-coating process with MORNLASER laser marking machine in below video:

Request an Offer

Click the chatbox on the bottom right side of your screen to get a laser cleaning solution or an offer of MORN LASER laser cleaning machine.