Table of Contents

The benefits of using laser welding to repair molds

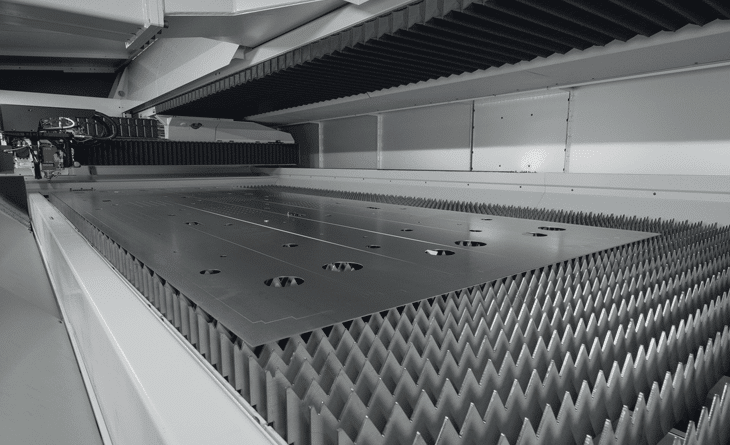

In terms of repairing molds, fiber laser welding technology makes up for the shortcomings of traditional argon arc welding technology in repairing welding fine surfaces, avoids the two thresholds of thermal strain and post-processing, and greatly saves the mold production cycle.

Mold repair

Mold plays an extremely important role in modern industry, and its quality directly determines the quality of the product. However, problems such as corner collapse, deformation, wear, and even breakage often occur during mold use. In order not to delay production, the mold needs to be repaired. At present, the most used methods for repairing molds are these two: fiber laser welding process and argon arc welding repair.

Repair of fiber laser welding process:

Laser welding is welding using a laser beam focused by a high-power coherent monochromatic photon stream as a heat source. This welding method usually includes continuous laser welding and pulsed laser welding. The advantage of laser welding is that it does not need to be carried out in a vacuum, but the disadvantage is that the penetration is not as strong as electron beam welding. Accurate energy control can be carried out during laser welding, so that the welding of precision devices can be realized. It can be applied to many metals, especially to solve the welding of some difficult-to-weld metals and dissimilar metals. It has been widely used for mold repair.

Argon arc welding repair:

Use the arc burning between the continuously fed welding wire and the workpiece as the heat source, and the gas shielded arc sprayed from the torch nozzle for welding. At present, argon arc welding is a common method, which can be applied to most major metals, including carbon steel and alloy steel. MIG welding is suitable for stainless steel, aluminum, magnesium, copper, titanium, zirconium and nickel alloys. Because of its low price, it is widely used for mold repair welding. However, it has disadvantages such as large welding heat affected area and large solder joints. Precision mold repair has been gradually replaced by laser welding.

Features of using fiber laser welding machine equipment to repair molds:

- It can realize spot welding, butt welding, stitch welding, sealed welding, etc., with high aspect ratio, small weld width, small heat affected zone, small deformation, and fast welding speed.

- Micro welding is possible. After the laser beam is focused, a small spot can be obtained, and it can be accurately positioned, which can be used in the assembly welding of micro and small workpieces that are automatically produced in large quantities.

- It can weld refractory materials such as titanium, quartz, etc., and can weld heterogeneous materials with good results.

- It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, when the laser passes through the electromagnetic field, the beam will not shift; the laser can be welded in vacuum, air and certain gas environments, and can be welded through glass or materials that are transparent to the beam.

- It can weld hard-to-access parts and non-contact long-distance welding, which has great flexibility. Especially in recent years, the use of optical fiber transmission technology in YAG laser processing technology has made laser welding technology more widely promoted and applied.

- High-power laser welding machine, which can realize various styles of laser welding machine and repair for thicker materials.

Morn laser

As an early manufacturer of laser welding machines, MORN Laser has always put the quality and application of laser welding machines in the first place. We always take “Quality is Social Responsibility” as our corporate purpose, and constantly research better welding solutions.

Our main products are laser welding machine, laser cutting machine, laser marking machine, laser cleaning machine, etc. MORN laser is waiting for you!