How to evaluate whether a laser engraving machine can work well or not? Or whether a laser engraving machine is worth being invested as a money-making aided tool. For these questions, you may find answers in the following 6 guidelines.

I. Specify your work nature

Please do not think that a single laser engraving machine is able to finish all jobs assigned. The purpose of classifying laser engraving machine into different models is to deal with different kinds of processing plans. For example, if you buy a top-level laser engraving machine to engrave double color plates or buy a large-scale laser engraver to engrave seals, then not only it will be a great waste of money and energy, but will also result in unsatisfying results. Therefore, you must talk to your suppliers sufficiently about your job content, including the texture, dimensions, thickness and weight of processing materials, engraving results and more.

II. Choose the right model

After you have a clear positioning on your work nature, it’s time to choose the right laser engraver model. According to your business, like an advertisement, furnishing, building materials, mining and so on, you should pay heed to the wattage, working area, accessories and technical support of the machine. In a word, precision and efficiency are the main aspects that constitute the ultimate goal of all considerations.

III. Try to engrave something before place an order

In order to personally see the engraving results and guarantee your investment return, it’s advised to try to engrave some materials you will process in future jobs. It can be conducted by the salesman or yourself, from which you can calculate the engraving efficiency, observe the results and have a good understanding of the engraver’s performance. Then, good or not, both will reflect in your mind.

Ⅳ. Contract signing

The first thing after the purchasing plan is done is to sign a sales contract with the supplier. You should carefully confirm the lase engraver model, configuration, price, time and way of delivery, warranty terms, payment type, etc. Once the contract is signed, you will pay some deposit as per the contract.

Ⅴ. Delivery

When the engraver you bought is delivered to you, technicians should verify whether there are damages on the machine and check accessories shipped with the machine. After examination, you should install the engraver in the right place and test its work performance according to the user manual. If all is right, you will pay the rest money to the supplier.

Ⅵ. Processing problems

a. To ensure the engraving precision, please heed the rationality of processing technology in addition to the engraver itself.

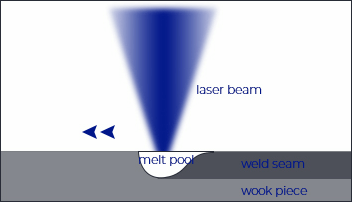

b. As the quality and precision of the laser head also have a great impact on processing precision, to choose a proper laser head is key to your jobs.

c.The operator of the laser engraver is the most subjective element in the whole processing work so that his/her working proficiency and responsibility play an important role in processing precision.

d.The wear and tear of a machine is unavoidable with time going by, which can also reduce the precision of engraving results.