The working speed of a laser engraving and cutting machine is now attracting increasingly more attention of laser operators. Since it closely concerns the work efficiency and productivity of your laser business. Hence laser operators are always looking for ways to increase productivity. Are you running your laser as efficiently as possible? Here are a few tips and tricks you can use to ensure that you are operating your laser at its highest potential.

1. A Dual Source Laser System is Worth Considering.

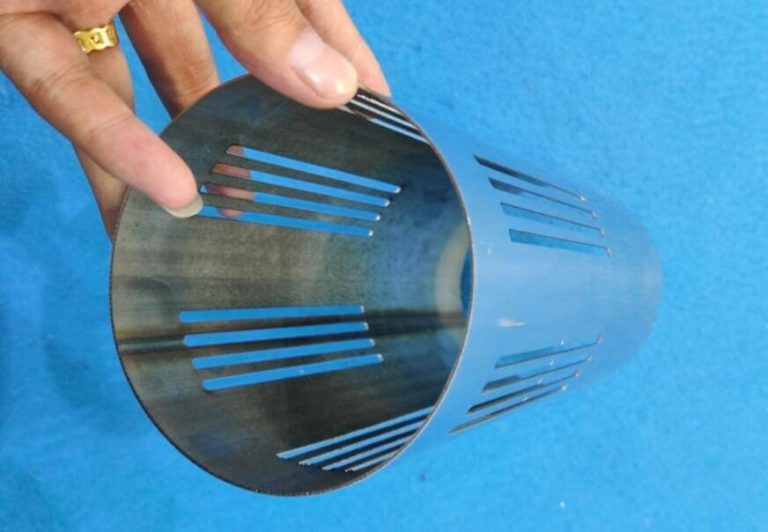

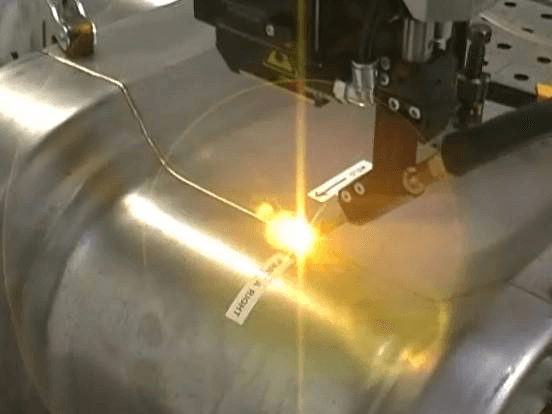

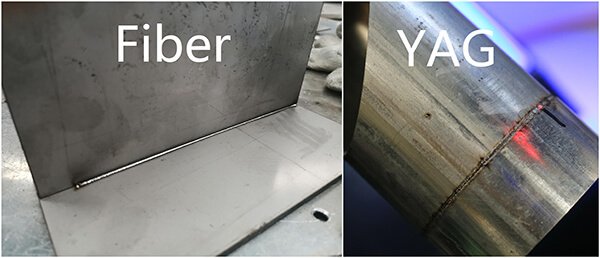

The CO2 laser engraver is a very versatile frequency of laser and works well with wood, acrylic, plastic, glass, marble and much more. What the CO2 systems don’t do, however, is engrave depth into metal, which is where the addition of the fiber laser source comes into play. Depending on the system, you either can switch out the sources, or they both operate in tandem, and you just choose when you want to use each source.

If you have limited shop floor space, a dual source system can also be a very appealing option. If you have the space for only one machine, then a dual source is a great way to maximize/double the productivity of your machinery without needing to expand your physical work space.

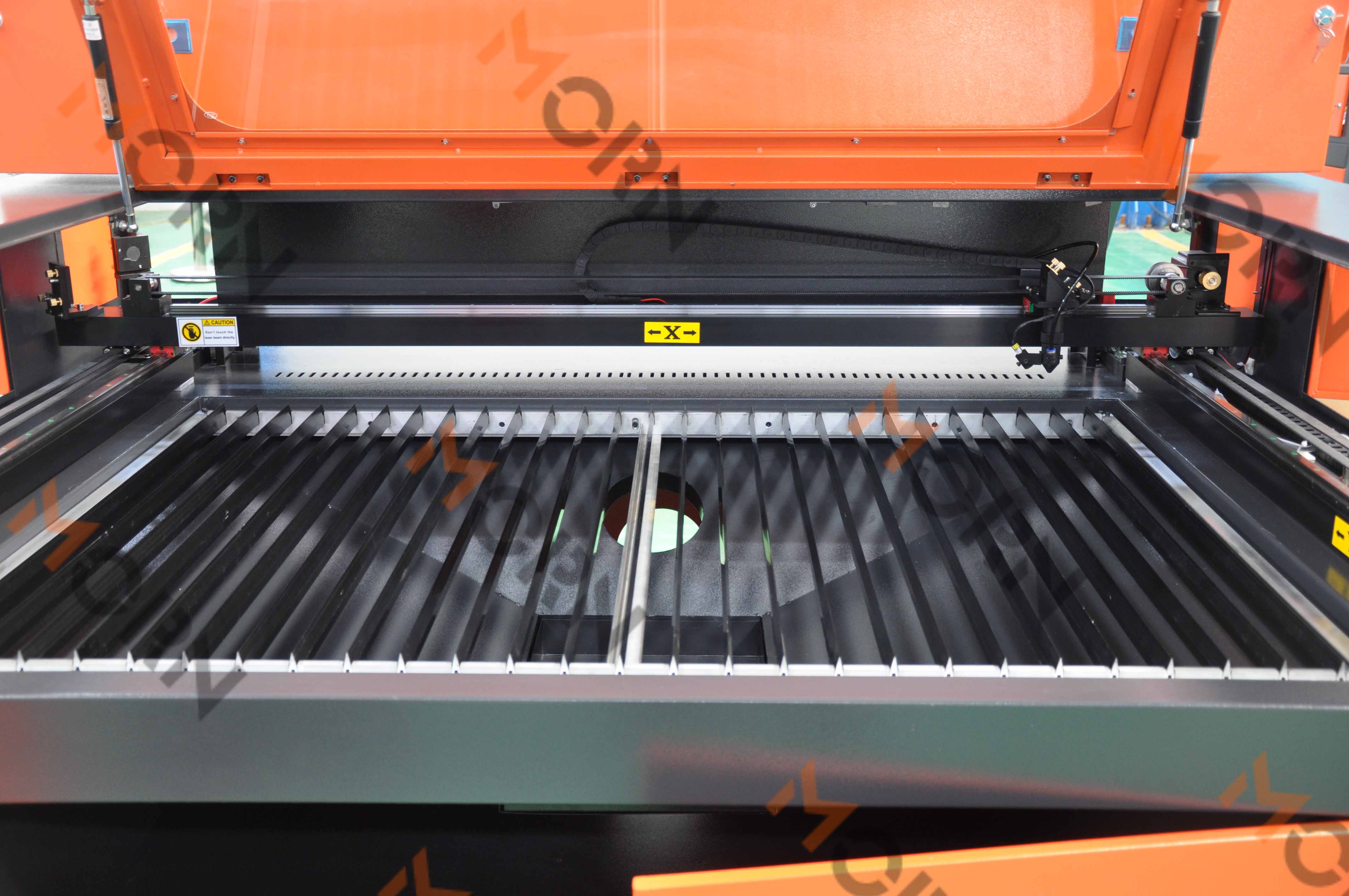

One thing that will reduce production time is printing multiples. If you have a project that requires engraving more than one item of the same or similar design – like plaques or coasters – print multiple pieces at once, instead of one at a time. We’ve found that by engraving in batches, users experience up to a 37% increase in time savings. How many you can engrave at once will depend on your table size, so to do this, you need to expand the page size in your graphic design program to match the full table size of your laser. You can then fill up an entire table with a particular piece and engrave them all in one run. Using a jig to properly space out the items can be helpful as well. At MORN, our engineers are always ready to provide custom laser solution for every application.

Resolution is another factor to consider when you want to increase throughput. A clear image is important in any engraving job, but the higher the DPI is, the longer an item will take to engrave. DPI refers to dots per inch, and the higher the DPI the closer together the engraved dots are going to be. This results in a highly detailed engraved image, but may take longer than you’d like. By lowering your engraving resolution a bit, you can increase your time savings by up to 33% or more. Do not reduce the resolution markedly, or the laser engraving machine will not produce satisfying results. Trying to find a balance that can both engrave good laser works and takes less time to produce.

If you are considering expand your laser business by upgrading you laser systems, we are ready to offer professional and customized solutions for you according to your work requirement. Just contact us for more details about our CO2 lasers or fiber lasers!