Table of Contents

How to judge the welding effect of laser welding machine?

Nowadays, laser welding machines are widely used, and there are numerous types of laser welding machines in the market. Although laser welding machines are widely used, the most worrying problem for users is how to identify the welding quality, and how to control laser welding machines is also very important for the welding effect, so how to judge the welding effect of laser welding machines?

I. Understand the welding method of laser welding machine

There are two commonly used laser welding methods, one is pulse laser welding, which is mainly used for welding single-point fixed continuous and thin materials, and forming round solder joints during welding; The other is continuous laser welding, which is mainly used for welding and cutting large and thick parts, and a continuous weld is formed in the welding process. Generally speaking, the selection of welding materials, laser welding machine and machining table are the main factors affecting the laser welding effect.

II. The judgment of melting phenomenon in the welding process

Whether or not the melting phenomenon can occur in the welding process and its degree of strength mainly depends on the time, power density and peak power of laser acting on the material surface. By controlling the above parameters, various welding processes can be carried out by laser. In laser welding, the beam focus position is one of the most critical control process parameters. Under certain laser power and welding speed, the maximum penetration and good weld shape can be obtained only when the focus is in the best position range.

III. Monitoring of tensile strength

The tensile strength can be monitored, and the problem of laser welding machine can be judged according to the inspection result. If there are problems such as poor welding and virtual welding of solder joints during processing, it may not be all the problems of the welding machine at this time, perhaps the materials are unsuitable. Re-weld after changing the materials or changing the waveform setting of the laser welding machine, and then evaluate the effect.

IV. The selection of laser welding machine frequency

Generally, when using laser welding machine, the frequency parameters will be adjusted as much as possible according to the customer’s requirements for efficiency. Frequency plays a great role in the requirement of welding efficiency, especially for some precise laser welding machines, when galvanometer and scanning system are used, the role of frequency will be even greater. How to adjust to the appropriate frequency will be a technical problem, but the role of frequency will also be related to other aspects, so it is necessary to have an overall effect in order to have a perfect welding effect.

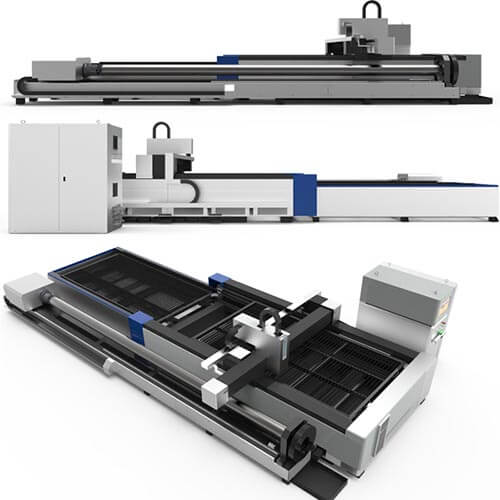

The fiber laser welding machine produced and sold by MORN LASER has the characteristics of good beam quality, thin spot and flexible installation, which provides conditions for more precise welding. Professional real-time energy feedback technology is adopted to ensure the stability of laser energy. Using optical fiber for transmission can be matched with different welding tables according to the requirements of different products. It can realize spot welding, butt welding, lap welding, seal welding, seam welding and penetration welding, etc., with high depth-width ratio, small weld width, small heat affected zone, small deformation, fast welding speed, smooth weld without air holes, no treatment or only simple treatment after welding, accurate control, small focusing spot, high positioning accuracy and automatic laser welding. Mainly used for stainless steel, aluminum alloy, steel, aluminum, gold, silver and other metals, welding of the same material and welding of different materials; Widely used in precision 3C digital products, instrumentation, medical equipment, hardware and electrical appliances, jewelry, kitchen and bathroom, electronic components, auto parts, craft gifts and other industries.