Table of Contents

How to choose the right laser welding machine?

Laser welding machines are playing an increasingly important role in the ever-changing technological changes. Their environmental protection, pollution-free, simple, and easy-to-operate features are increasingly being valued in modern industrial production. Laser welding machine is commonly called laser welding machine or laser welding machine, mainly used for welding metal. Its non-contact welding method can better complete many difficult welding.

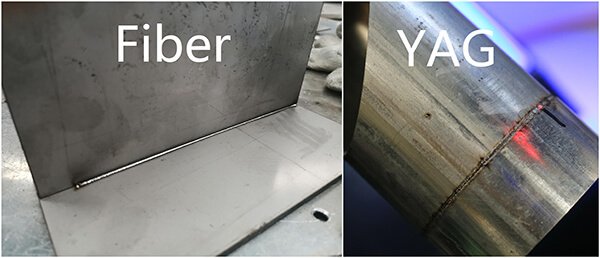

Laser welding machine is mainly divided into three categories. The first type is YAG laser welding machine. The second type is the optical fiber transmission laser welding machine. The third type is the continuous laser welding machine also known as fiber laser welding machine. The main features (advantages and disadvantages) of these three types of welding machines are described below.

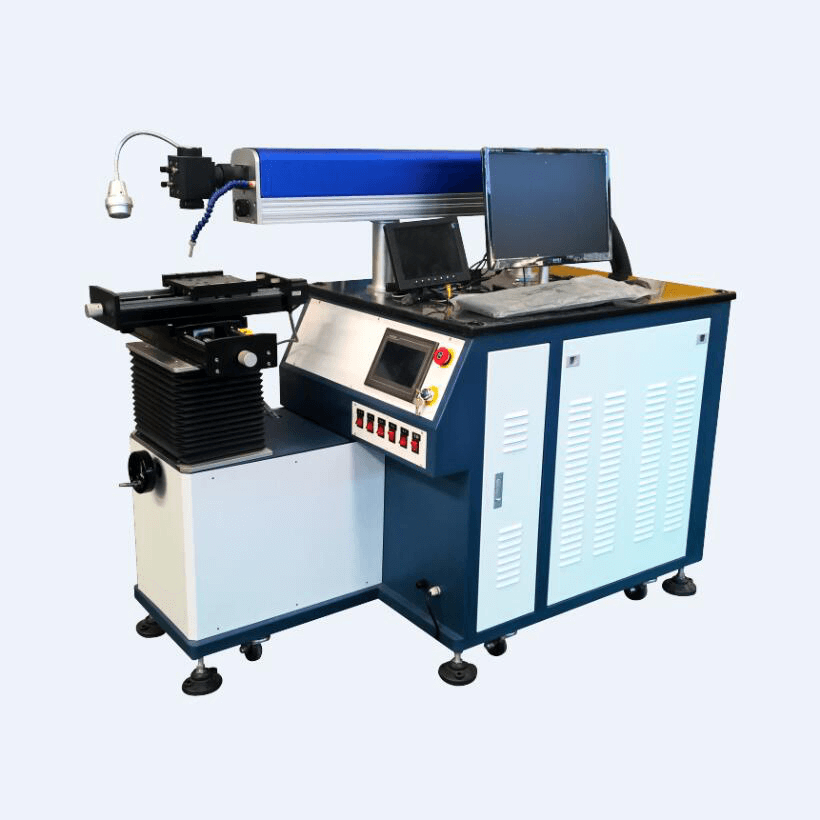

The first type: YAG laser welding machine

YAG laser welding is to weld the workpiece with high-energy pulsed laser. It uses pulsed xenon lamp as the pump source and Nd: YAG as the laser working material. Firstly, the pulsed xenon lamp is premixed by the laser power supply, and the xenon lamp is discharged by the laser power supply to generate light waves with certain frequency and pulse width. The light wave irradiates the Nd: YAG laser crystal through the concentrating cavity to generate laser, and then generates the pulse laser with the wavelength of 1064nm after passing through the resonant cavity. The laser is expanded, reflected (or transmitted through optical fiber) and focused Then it radiates to the surface of the workpiece to melt the workpiece locally to realize welding. The frequency, pulse width, moving speed and moving direction of the pulse laser needed in welding can be controlled by PLC or industrial PC, and the laser energy can be controlled by adjusting the current size, laser frequency and pulse width.

Advantages:

- 1.High depth-width ratio. The weld is deep and narrow, and the weld is bright and beautiful.

- 2.Due to the high power density, the melting process is very fast, the heat input of the workpiece is very low, the welding speed is fast, the thermal deformation is small, the heat affected area is small.

- 3.High density. In the process of weld formation, the weld pool is constantly stirred and gas escapes to form a porous penetration weld. The high cooling rate after welding makes the weld microstructure fine, and the weld strength, toughness and comprehensive performance are high.

Disadvantages:

- Relatively high energy consumption and power consumption, the power per hour is 16-18KW.

- The solder joints are not uniform in size.

- Slow welding speed.

- The laser tube often to replace, about half a year to replace.

The second type: optical fiber transmission laser welding machine

Optical fiber transmission laser welding machine is a kind of laser welding equipment that combines the high-energy laser beam into the optical fiber, transmits it to the parallel light through the collimator, and then focuses on the workpiece for welding. For the inaccessible parts of welding, the flexible transmission non-contact welding is carried out to have greater flexibility. The laser beam of optical fiber transmission laser welding machine can realize the time and energy splitting, and can process multiple beams at the same time, which provides conditions for more precise welding.

Advantage:

- It is convenient to use CCD and laser transmission system.

- The energy distribution of the welding spot is uniform, which has the best spot for welding characteristics.

- Optical fiber transmission laser welding machine is suitable for spot welding of various complicated welding seams, various devices, and seam welding of thin plates within 1 mm.

- Special automatic chemical fixture can be customized to realize the mass production of products.

Disadvantages:

- High energy consumption and relatively low power consumption. The power consumption is about 10kwper hour.

- The welding speed is relatively slow.

- The penetration depth is shallow, so it is difficult to realize deep welding.

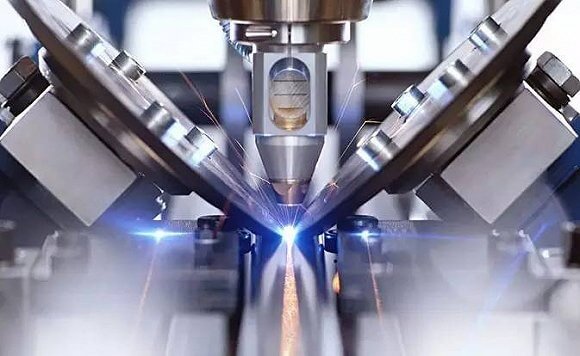

The third type: fiber laser welding machine

Fiber laser welding machine is a continuous laser directly produced by a high-power fiber laser, which is different from pulsed lasers. The fiber laser welding machine has good light output and stable performance.

Advantage:

- The laser beam quality is excellent, the welding speed is fast, the efficiency is high, the welding is not deformed, the color does not change, and the welding seam is firm and beautiful.

- Industrial PC control, the workpiece can move on a plane trajectory, and can weld any plane graphics composed of points, straight lines, circles, squares or straight lines and arcs.

- The longest life of all welding machines.

- Highelectro-optical conversion rate, low energy consumption, long-term use can save users a lot of processing costs.

- 5. The equipment has high reliability and can be processed continuously and stably for 24 hours to meet the needs of industrial mass production and processing.

- 6. Due to the small size of the machine and the soft light path, it can be used with most tooling and automation equipment

Disadvantages:

Compared with other welding equipment, the price is slightly higher.

Above are the description about the classification, advantages and disadvantages of laser welding machines. Hope they can help you choose the right laser welding machine.