Laser cutting of metal has been around for a couple of decades now, but there still appears to be some confusion of which laser is suitable for which application. Although metal can be successfully cut using plasma or water jet cutting machines, when it comes to accuracy and consistency it has to be a fiber laser cutting machine.

Today’s manufacturing industry is majorly concentrating on precision and pace of manufacturing the component. It is the fact that different tool is required to perform different operations on the component, hence there is a time factor involved in changing the tool. This ultimately results in loss of time which incurs cost. To minimize this time, fiber laser metal cutting machines have been introduced in the metal manufacturing industry. Here, the machine doesn’t get in contact with the materials, which means there is no wear and tear of tool, where the cost of renewing tool is zero.

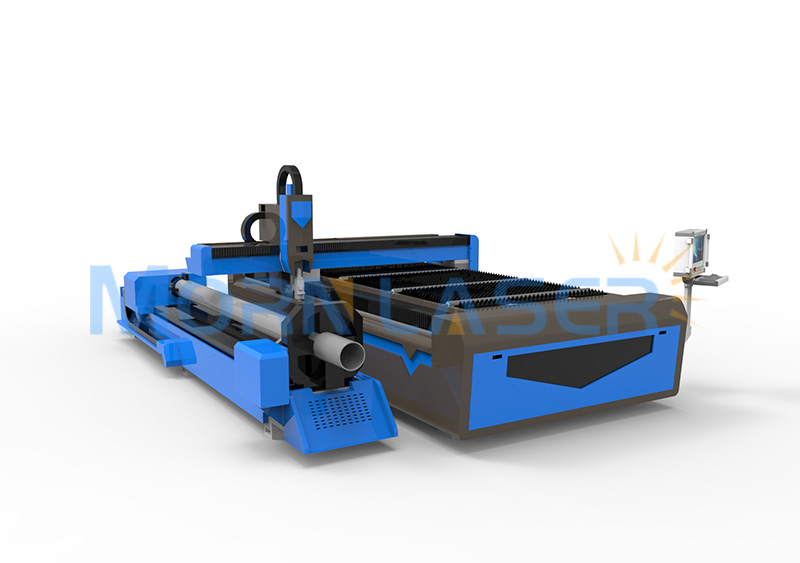

There is a huge market for laser machines in industrial activities as the manufacturers are realizing the advantages of switching to the laser technology. We at MORN promote fiber laser machines which reduce time and cost of manufacturing, which is advantageous to the manufacturer as well as the buyer.

The benefits of a fiber laser cutting system include:

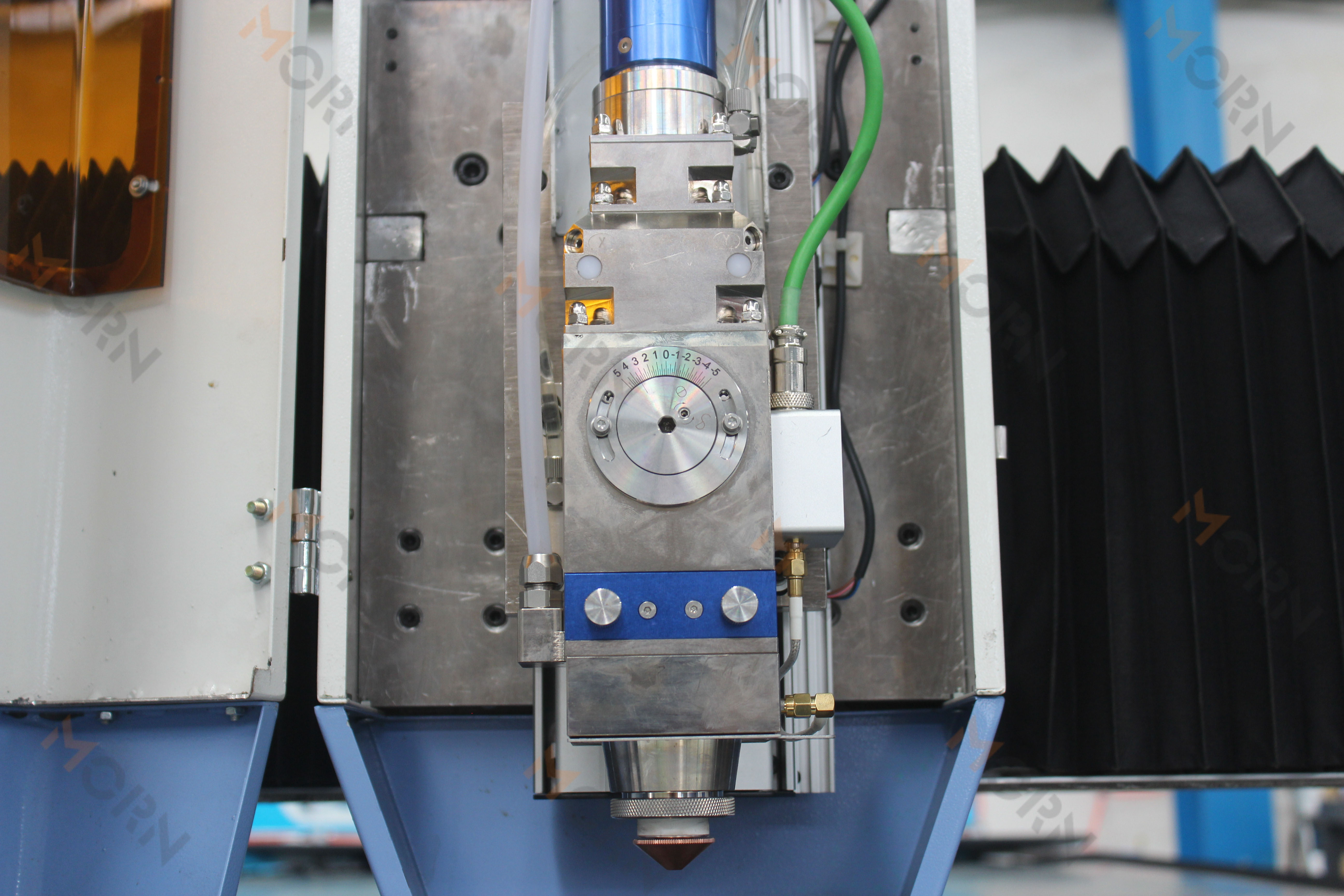

- There are no moving parts or mirrors in the light generating source. This reduces the maintenance requirements and operating costs.

- The electrical efficiency is high which results in lower running cost.

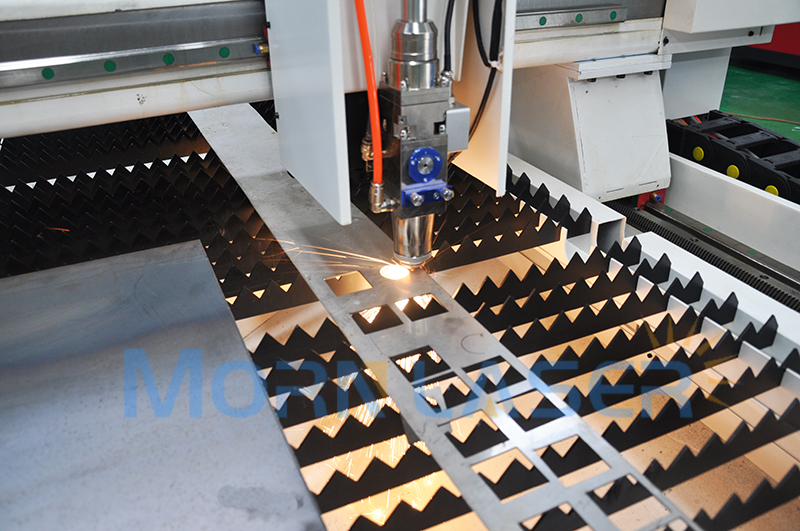

- The speed of cutting thin materials is high.

- It has the ability to cut reflective materials and there is no problem of back reflection.

What is the reason that more and more entrepreneurs decide to buy cutting machines that cut in fiber laser technology? Just one thing is certain – the price is no reason in this case. The cost of this kind of machine is the highest. So it must offer some possibilities that make it technology leader.

This article will be a recognizing of all cutting technologies working terms. It will be also a confirmation that a price is not always the most important argument for investment. On the other side there will present some useful information which can be helpful during the choosing the best model of fiber laser cutting machine.

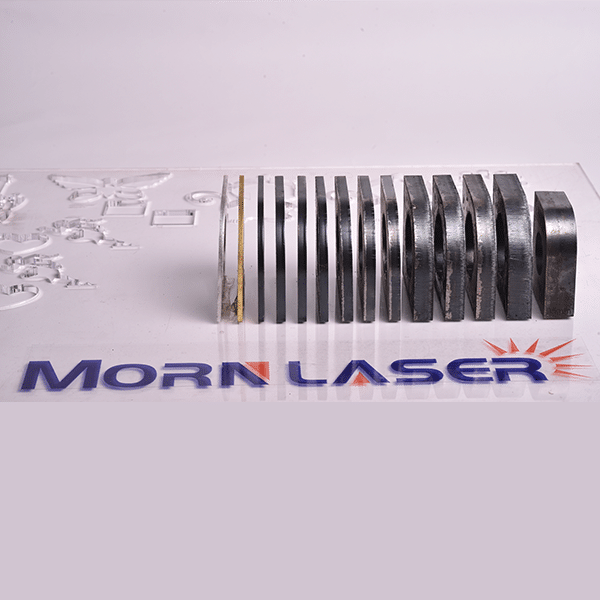

If you would like to analyse cutting precision of a fiber laser cutting machine for metals, the fiber laser is the best technology. It is even 12 times better than plasma cutting and 4 times better than water cutting. So, the fiber laser cutting will be the best solution for the companies that need get the masterpiece of precision, even for the most complicated elements. The one of reason of this level of precision is very narrow cutting gap.

Nowadays, the fiber laser cutting technology is the most universal method for metal parts and components manufacturing industries. It can cut a lots of materials – metals, glass, wood, plastic and many other. It is also the master of precision and look of cut out elements. If you use thin materials often, the fiber laser metal cutting machine is the most optimal choice for you.

When you made a decision and chose fiber, you must think about the model. It doesn’t mean the machine manufacturer’s analyse only. It means parameters. There are many parameter combinations that determine the best choice of solution for your business. Now, there will be a major combined various parameters: lasers power, cutting speed and material thickness, which can basically decide your fiber laser cutting performance.

If you do correct analysis of market, you can avoid many mistakes when choosing a fiber laser cutting system. You should know the newest solutions. Any doubts you should discuss with specialist. This approach to the purchase of the fiber laser machine gives you a real possibility to avoid wasting of money and make your advantages stronger.

For more information about MORN fiber laser cutting machine, please contact us and let us know your concerns. We are looking forward to working with you for a most suitable fiber laser solution for your business.