Table of Contents

This is my European client-real case:

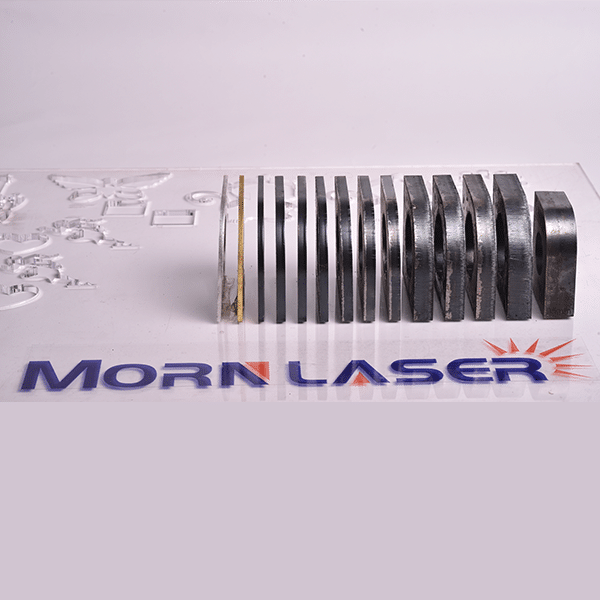

Before using laser cutting, European electrical equipment manufacturers have been using traditional punching machines to manually grind edges and corners and deburr, with low accuracy, numerous failures, and annual turnover. By chance, the boss learned about the laser cutting technology. After comprehensive consideration and repeated consideration, he found that the laser process is far superior to CNC punching equipment in processing speed, and after the cutting is completed, the section is very smooth, without additional manual processing at all, which can greatly reduce cost. After some inspection, the factory began to use fiber laser cutting machines, and the benefits have been greatly improved. The annual turnover has jumped from 2 million to 10 million. Many manufacturers have turned to the factory for on-demand processing. So far, the factory has entered a higher-end and higher Levels of competition!

The development of any industry is inseparable from forward-thinking visionaries who know how to use advanced equipment and advanced technology to replace expensive labor, and know how to save costs to the greatest extent and increase product added value. The rapid rise of fiber laser cutting machines in various industries has resulted in more and more developments and changes in similar industries. More and more industry leaders are beginning to realize that the revolutionary era of laser applications has arrived.

How to choose the right fiber laser cutting machine?

Before answering this question, I need to ask you to do a self-analysis of yourself and your factory:

1, What is the current processing volume of our factory and the market survey of the peripheral external sheet metal processing volume? Then specify these indicators: what sheet? How thick is it? How complex is the processing graphic? Laser processing fit, etc.

2, What is the current output value of our factory and what is the budget for laser cutting?

3, Estimated processing volume and output value of our factory within half a year/one year, and setting of future development direction, etc.

After thinking about these issues, if you have doubts or plan to wait and see, there is no need to read it anymore. Please go back to the beginning of the article by yourself: Why choose fiber laser cutting machine? Motivation determines the outcome of everything. Think clearly why doing is more important than how to do it. If you are more determined to buy a machine, then congratulations, you will gain after reading the following article.

Choosing a fiber laser cutting machine that suits you instead of the cheap laser cutting machine or the fastest fiber laser cutting machine requires comprehensive consideration of fiber laser cutting machine hardware configuration, manufacturer professionalism, price acceptance, after-sales service and added value Wait.

Hardware Configuration:

The fiber laser cutting machine is mainly composed of many subsystems such as light path system, bed system, servo drive system, water cooling system, software control system, and water cooling system. As a whole system, the fiber laser cutting machine requires that the various subsystems must be highly coordinated. Therefore, each component selection of the integrated manufacturer must undergo repeated testing and installation tests, and multiple selections will be considered;

Professional manufacturer:

Due to the vigorous development of the industrial application of laser cutting machines, various CNC punching and plasma manufacturers have stepped into the field of laser cutting machines. The level of fiber laser cutting machine manufacturers varies greatly. Therefore, when choosing a laser cutting machine, you must keep your eyes open and look for manufacturers that focus on laser industrial applications. Dedication can be professional, and professional can be trusted.

Price factors:

As the actual purchaser of fiber laser cutting machines, we are more often in a misunderstanding. We always measure the ratio and price of each company, and always want to choose a company with the highest configuration, the cheapest price, and a brand company. , Entanglement and entanglement, more than half a year has passed, and the peers have made enough money for half a year, but you are still standing still day after day.

The choice of fiber laser cutting machine cannot only consider the price factor. Assuming that based on the price factor, you buy a laser device for a cheap price of 20,000 yuan, but after you buy it, you can’t use it normally and frequently replace parts. Replacement parts alone are more than 2 Ten thousand, let alone the loss caused by the impact of normal production, in 5 years, the loss of a single part has reached 100,000, let alone whether it can be used for that long.

After-sales service:

In all mechanical service industries, after actual use, what the user is most worried about and needs most is the timeliness and continuity of after-sales service. Must ensure the normal operation of the machine to ensure production. Let professional people do professional things, even if there is simple training that can easily handle some subtle problems, it is not as convenient and assured to let professional manufacturers contract after-sales problems.

The high-standard commitment of machinery and equipment after-sales service is not only to give customers confidence in a choice, but also a manifestation of their high standards: from market positioning to mechanical design, from procurement, assembly, quality inspection, and even after-sales Only by demanding a strict system can we stand the test of the market.

Additional value:

Buying machines is buying benefits, buying time, and buying money-making machines;

Buying a machine is also a way of production and management, a broader circle of friends, and even a laser era;

Choosing a fiber laser cutting machine is the most direct and popular way to make money; in a comprehensive way, the added value of this laser cutting machine includes saved material costs, labor costs, time costs, including orders that increase product value. , Including the transformation of production and management methods, more and higher-level business partners, and more importantly, let you walk in the forefront of the times. Choose laser cutting, then you will lead the entire industry.