For the application of metal laser cutting machine, the quality of cutting is the primary condition to consider. With good cutting quality, metal laser cutting machine can create value for the metal fabricators. Therefore, it is necessary to master the factors that affect the cutting quality. Then what factors can affect the cutting quality of metal laser cutting machines? Let’s dive into the details.

Table of Contents

Effect of Cutting Speed on Metal Laser Cutting Quality

The cutting speed is inversely proportional to the density (specific gravity) and thickness of the material being cut.

Proper cutting speed ensures smooth cutting lines, a smooth transition of the cutting section, and no melting of the lower part of the workpiece.

Effect of too high speed on metal laser cutting quality

- May cause cutting failure with sparks all around see Figure 1.

- Some areas can be cut off while others cannot.

partially cut off, partially not

Cutting effect of too fast speed (back of workpiece)

- The cutting section is rough.

- The cutting section has a diagonal stripe path, and excessive slag is generated in the lower half of the workpiece.

Effect of too low speed on metal laser cutting quality

- May lead to over-melted sheet metal and rougher cutting fracture surface.

- The kerf will be wider which may lead to lower cutting precision, and the small rounded corner or sharp corners may be melted.

- Low cutting efficiency influences production capacity.

Appropriate metal laser cutting speed selection

The feed speed can be judged from the cutting spark. The sparks will be diffused downwards in normal cutting, and when the speed is too high, the sparks will be banked; In case the sparks are not diffused but gathered together, it indicates that the feeding speed is too low.

Effect of Nozzle on Metal Laser Cutting Quality

The airflow condition will be different based on different nozzle designs, which will affect the cutting quality directly.

Main functions of the nozzle

The role of the cutting nozzle is

- To prevent the debris such as the melting material from rebounding upwards and entering the nozzle to damage the lens.

- To control the area and size of gas diffusion, it plays a role in controlling the quality of the cut.

Effect of nozzle height on the metal cutting quality

When cutting normally, the following height of the nozzle (distance between the nozzle and the workpiece) generally should be kept at 0.8mm-1.2mm.

Too low height may result in a collision of sheet metal and nozzle, and too high height will result in gas diffusion, causing many residues at the cutting bottom surface.

Furthermore, in order to ensure high-quality cuts during the use of the metal laser cutting machine, the height of the cutting nozzle to the surface of the cut workpiece must be kept substantially the same.

Modern laser cutting machines are equipped with an inductive or capacitive sensor feedback device to automatically adjust the distance between the two to a predetermined height range.

Effect of nozzle diameter on metal laser cutting quality

Due to the difference of metal sheet, power, and auxiliary gas, the choice of nozzle aperture will also change accordingly.

The nozzle has a diameter of φ1.0 mm, φ1.5 mm, φ2.0 mm, φ2.5 mm, φ3.0 mm, and the like. At present, the nozzle aperture is often used in two sizes: φ1.5 mm and φ2 mm.

In general, when the nozzle diameter is small, the gas velocity is high, and the molten materials eliminating ability is strong. It is suitable for thin plate cutting, by which, the fine cutting section can be achieved.

When the nozzle diameter is large, the gas velocity is low and the molten materials eliminating ability is poor. It is suitable for cutting thick plates at a low speed.

In case a nozzle with a larger aperture is used to cut the thin sheet rapidly, the residue produced may be spattered upwards, damaging the protective lens.

Effect of nozzle deformation on metal laser cutting quality

During the cutting process, when the nozzle collides with or rubs against the workpiece, the nozzle is easily deformed. The deformed nozzle will affect the concentricity of the center of the nozzle with the laser beam.

When the center of the nozzle and the laser beam are in different axes, there will be the following adverse effect:

- It will affect the quality of cutting section. The auxiliary gas blown out of the deformed or melt nozzle is not uniform in volume, causing cutting section burnt or melt on one side. This could be even worse when cutting metal sheets with thickness above 3mm. Sometimes, it cannot cut through.

- It will affect the quality of sharp corners. When to cut sharp corners, local over-melting is likely to occur. When cutting thick slabs, it may not be able to cut off.

- It will affect the perforation. The perforation is unstable, the time is not easy to control. The penetration of the thick plate may cause over-melting, and the penetration condition is difficult to control. The perforation of the thin plate is less affected.

Therefore, the nozzle should be placed carefully and should not be damaged to avoid deformation; the melts on the nozzle should be cleaned up in time. Meanwhile, the nozzles should be highly accurate when manufactured and properly installed. If the conditions are changed during cutting due to poor nozzle quality, the nozzle should be replaced in time.

Effect of Ceramic Ring on Metal Laser Cutting Quality

The ceramic ring is an important part of the cutting head of the metal laser cutting machine. Its main function is to transmit the electrical signals collected by the laser head nozzle, which plays an important role in the normal and stable operation of the laser cutting machine.

The laser ceramic ring structure is mainly composed of ceramic body, stainless steel parts and copper needles. The ceramic body is mainly used to maintain the insulation of the laser head body. The stainless-steel piece is used to ensure sufficient contact with the nozzle, thereby transmitting an electrical signal to the copper needle, and the copper needle transmits an electrical signal to the transmission line, the signal is then sent to the controller by the circuitry inside the laser head.

We often encounter equipment failures for no reason, laser head hitting the working surface and other faults. In fact, it is caused by the instability or loss of the electrical signal caused by the poor laser ceramic ring.

Then how to select ceramic rings?

- Choose ceramic ring with gold plated copper needle. In order to reduce the loss during signal transmission, the copper needle of a good ceramic ring is electroplated with pure gold because gold has the best conductivity.

- Check the quality of the ceramic body. The upper and lower faces of the ceramic body should have a high degree of parallelism. At the same time, the tapered surface of the upper part of the ceramic body should have a high degree of smoothness, and there should be no bumps or scratches, otherwise the eddy current may be easily generated and the cutting effect may be affected.

- Check assembly quality. The stainless-steel piece should be closely attached to the ceramic body, and there should be no lifting, deformation or gap.

Ceramic rings, nozzles and protective lenses are small but important consumables for laser cutting machines, choose the right product, not necessarily the best, but must ensure the quality, in order to protect the laser cutting Protection

Effect of Laser Power on Metal Laser Cutting Quality

Laser power has a decisive influence on the cutting process and quality.

Choosing the right cutting power for cutting, the cutting section will be smooth and no melting.

- If the laser power is too small, the heat is insufficient, and the temperature of the molten product near the lower edge is lower, and the viscosity is higher so that it cannot be completely blown off by the high-pressure airflow and stays on the lower edge of the cutting surface to cause dross. In severe cases, it is not even possible to cut and form an incision.

Dross caused due to too small power

- If the laser power is too large, the heat input is too large, so that the melting range of the workpiece is larger than the range that can be driven out by the high-pressure airflow, and the molten metal is not completely blown off by the airflow to generate over-burning.

Over-burning and wide kerf caused due to too large power

Effect of Focal Length of Lens and Focus Position on Metal Laser Cutting Quality

Short focal length lenses are suitable for high-speed cutting thin materials, whereas long focal length lenses are suitable for cutting thick workpieces.

We define the focus position as 0 on the top surface of the workpiece. The focus is positive above the top surface of the workpiece and the focus is negative below the top surface.

The thicker the workpiece and the higher of the focus, but the height of the focus should be kept in certain range. If it is out of range, it will not be cut or even cut through.

When the positive focus cuts 16mm carbon steel, if the focus is too high, and the lower surface of the section will be covered with melts; if the focus is too low, and the lower surface of the section will be covered with oxide scale

Positive focus 16mm carbon steel cutting section

When cutting 8mm stainless steel, it is suitable to use negative focus cutting. The focus position is below the surface of the plate, the cutting surface is uniform, and the cutting section is good. However, when cutting the right angle, it is easy to reflect blue light and the cutting ability is limited.

Negative focus 8mm stainless steel cutting section

Customers can choose the right focus cutting method according to the different effects of positive and negative focus in cutting stainless steel and carbon steel, combined with their own processing needs, so as to maximize the production efficiency.

Effect of Auxiliary Gas on Metal Laser Cutting Quality

The auxiliary gas can not only blow away the slag in time but also play the role of cooling the workpiece and cleaning the lens. Different auxiliary gases can be used to change the cutting speed and the surface quality of the kerf. It is of great significance for the cutting of special metals.

Selection of auxiliary gas

Generally, compressed air is suitable for the cutting of aluminum, non-metallic and galvanized steel sheets, which can reduce the oxide film and save costs to some extent. It is used when the cutting plate is not very thick, and the requirements of cutting end face is not too high, such as some sheet metal chassis, cabinets, and other product industries.

Nitrogen is an inert gas that prevents oxidation of the cut end face of the product during cutting and prevents combustion (it is easy to occur when the sheet is thick. Nitrogen can be selected for products that require high cutting end faces and are not treated. For example, some decorative industries, aviation special parts such as aerospace;

Oxygen mainly acts as a combustion aid, which allows the laser cutting machine to increase its speed during cutting and thicken the cutting thickness. Oxygen is suitable for thick plate cutting, high speed cutting and very thin plate cutting, such as some large carbon steel plates and some thick carbon steel structural parts, can use oxygen.

Effect of auxiliary gas purity on metal laser cutting quality

The purity of nitrogen affects the quality of the cut. Water will cause damage to the laser, so the gas level should be at least 4.5.

Practice has shown that A 2% reduction in oxygen purity reduces the cutting speed by 50% and results in significantly worse cut quality.

Effect of auxiliary gas pressure on metal laser cutting quality

1) When the pressure of the cutting gas is too high, the cutting surface is rough and the slit is wide; meanwhile, the cut section is partially melted, and a good cutting section cannot be formed.

2) When the pressure of the cutting gas is insufficient, the melt is generated during cutting, and the cutting speed cannot satisfy the production efficiency.

Effect of Processing Material on Metal Laser Cutting Quality

The treatment of the surface of the processing material has a negative effect on laser cutting such as galvanized, painted, anodized or covered with layered plastic film, etc. Zinc-treated sheets may result in slags on the edges.

Plates with rusts, oils, embroidered spots should be cleaning first and then cut; in case of unable to be cleaned, the power and pressure of auxiliary gas should be increased to avoid the incomplete cut.

If there is a rusty area or an oxide layer on the surface, the contour of the cut will be irregular and many breakpoints will appear.

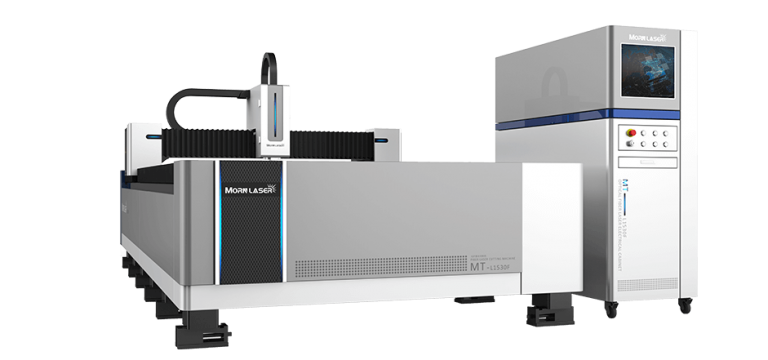

The above is the effects of the external factors of metal laser cutting machines on the cutting quality of the workpiece. However, the important factor of the cutting quality lies in the quality of the metal laser cutting machine itself, so it is necessary to choose a powerful manufacturer to buy equipment. Jinan MORN LASER has 20 years of experience in the laser cutting machine manufacturing industry. With strong technical strength, it has established a good reputation in the industry. Welcome customers to consult more details.