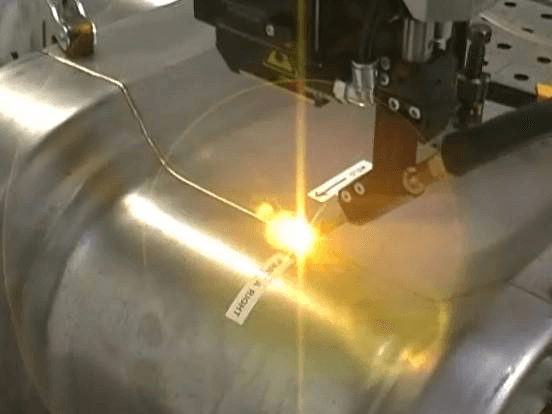

Fiber Laser Cutter is one of the most extensive processing methods in the laser processing industry. The whole machine is stable and reliable, with good dynamic performance and strong load capacity. It is a high-tech product integrating laser cutting, precision machinery, numerical control technology and other disciplines. It has the characteristics of high speed, high precision, high rate and high cost performance.

Table of Contents

Protective measures of the machine

Designate safety administrators, determine their scope of responsibility, and conduct safety operations and safety protection education for laser processing operators.

Designate laser safety management areas, and set up warning signs at the entrances and exits of the management areas, including: the power of the laser processing machine, the type of laser, prohibiting outsiders from entering, and protecting eyes, etc.

When the laser processing machine is not in use, the switch key should be pulled out and kept by a dedicated person to avoid harm caused by misoperation by idle personnel.

The fume gas and laser working gas generated during the processing should be discharged to the outdoors through the exhaust pipe, and all gas cylinders should be placed neatly and firmly.

User common sense

The operator of the laser processing machine must be specially trained to reach a certain level, and can only operate on duty with the consent of the safety administrator.

The operator of the laser processing machine or the person approaching the laser during laser use should wear appropriate laser protective glasses and protective clothing. In the protective glasses area, there must be good indoor lighting to ensure the smooth operation of the operator operating.

In order to protect the operator, a processing room or protective screen must be provided. The processing room should be equipped with a device to prevent laser diffusion and protect the safety of the operator; when the processing room is opened, the laser shutter should be closed.

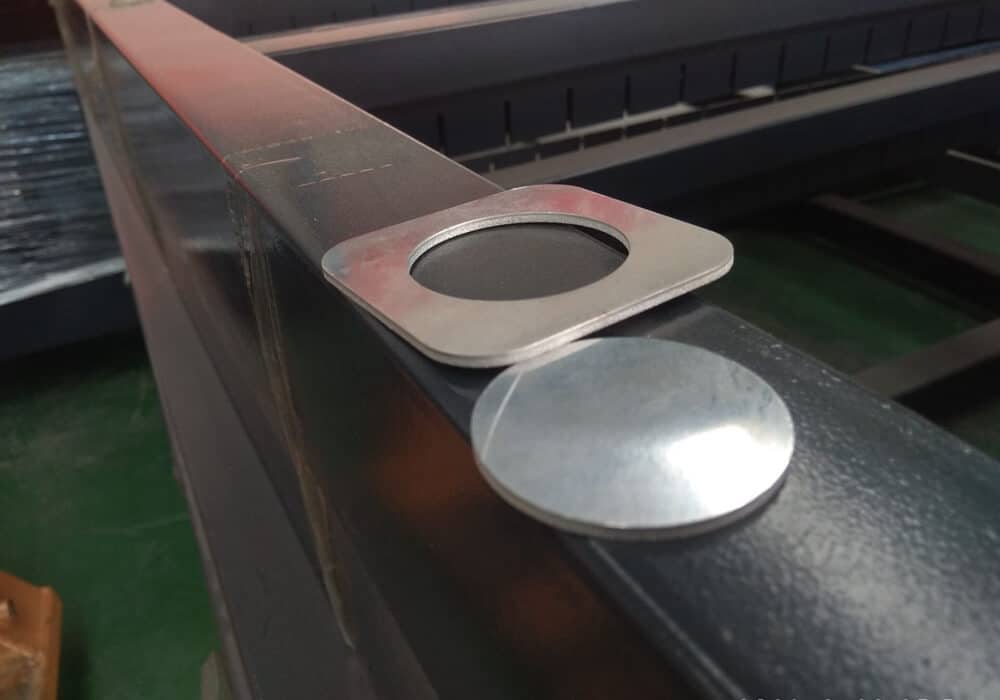

1. Necessary protective equipment for laser cutting machine.

The typical protective equipment for fiber laser cutting machines is laser protective goggles, because protective goggles that prevent laser damage to human eyes can be divided into reflection, absorption, diffraction and composite types according to their protection principles. Of course, They will filter and protect according to the laser radiation wavelength of the laser cutting machine to achieve the protection of the laser cutting machine laser of the human body, which is also a safer and convenient protective equipment on the market.

2. Self-protection against the radiation of fiber laser cutting machine.

If the human body is sufficiently healthy, it can resist the slight radiation of the cutting machine. Therefore, operators should pay attention to eating more carrots, bean sprouts, tomatoes, lean meat, animal liver and other foods rich in vitamin A, C and protein, and often drink green tea and so on. Because these foods can help humans to better protect the eyes, and the human body can better protect the human body under the conditions of radiation from the cutting machine.

When using a fiber laser cutting machine, the operator must not only learn to operate correctly, but also protect the use environment of the equipment. We must master our own protection and take protective measures.