Table of Contents

The characteristics and application of tube and sheet laser cutting machine

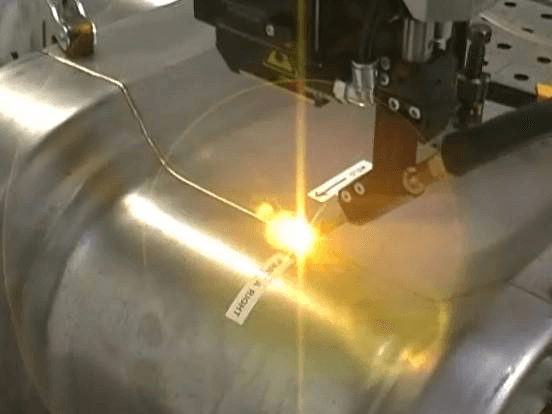

Tube laser cutting machine is different from the single plate or tube laser cutting machine. The tube and tube integrated laser cutting machine has fast cutting speed and small slit width. It has the double cutting function of plate and tube, and can realize the automatic cutting and processing of upper and lower materials.

Laser cutting machine manufacturer plate and tube combined optical fiber laser cutting machine applicable industry:

Widely used in sheet metal processing, aerospace, aviation, electronics, electrical, high-speed rail and subway parts, auto parts processing, grain machinery, textile parts, ships, metallurgical equipment, elevators, household appliances, kitchen supplies, tool processing, decoration, advertising and other metal materials processing and manufacturing industries.

Plate tube main characteristics of fiber laser cutting machine can not only reduce cover an area of space, also can reduce the cost, is a double cut sheet and pipe needs the user’s ideal choice, the use of advanced brand fiber laser and electronic components, guarantee the stability of the equipment, pipe cutting device, offer sheet and pipe double cutting function; It is convenient for drawer type to collect debris and workpiece and clean up.

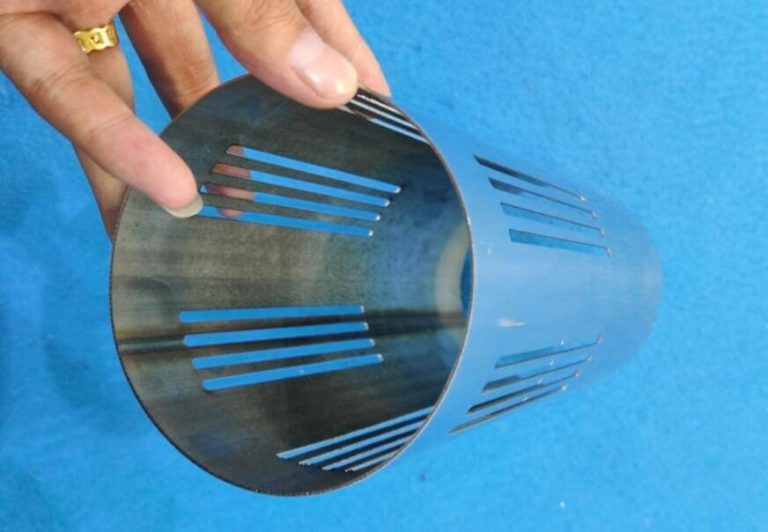

It can cut stainless steel, carbon steel, galvanized plate, aluminum plate, copper, brass and other metal materials with high speed and high precision. It is also suitable for cutting square pipe and flat round pipe. It can punch holes, cut graphics and cut intersecting line (at any Angle), and the loss of the machine can be greatly reduced compared with the general optical fiber laser cutting.

There are two advantages:

One is flexibility.

How can a tube-plate integrated fiber optic laser cutter be called flexible? You can cut it any way you want, it cuts in stainless steel in a programmed shape, and the laser cuts in the direction. The shape to be machined can be changed flexibly through computer programming. The flexibility of the tubesheet integrated fiber laser cutter supports more and more personalized processing, thus reducing the number of molds used.

The second is precision.

Compared with the traditional flame cutting, water cutting and other processing equipment, tube plate integrated optical fiber laser cutting machine cutting of sheet metal precision is much higher, at the same time, as mentioned above, may occur in the manufacturing process of different materials in small scale deformation, tube plate integrated optical fiber laser cutting machine can be adjusted according to the deformation, and it is also a lot of traditional craft.

Application of tube and plate integrated laser cutting machine in tube and plate processing:

Can high speed and high precision cutting stainless steel, carbon steel, galvanized sheet and aluminum plate, copper, brass and other kinds of metal materials, and is suitable for cutting square tube, round tube, rectangular tube, oval tube, oval tube, slitting, punching, cutting the curve graphics, cutting (arbitrary Angle), and the wastage of the machine to reduce general laser cutting machine to a large extent.

Tube plate integrated laser cutting machine features:

- Small size, light weight, suitable for outdoor work, low energy consumption, no need for drawing and simple operation;

2, can open inside, outside, “X” and “Y” groove, suitable for the center of the pipe is not good;

- Double sprocket structure has a longer life, flexible track is rough for steel pipe and has strong deformation adaptability.

Application scope of tube-plate integrated laser cutting machine:

Can cut steel pipe, stainless steel pipe, cast iron pipe, etc., suitable for natural gas pipe, petroleum pipe, city gas pipe, large diameter chemical, water pipe, etc. Widely used in sheet metal processing, aerospace, aviation, electronics, electrical, high-speed rail and metro accessories, auto parts processing, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgy equipment, elevators, household appliances, kitchen supplies, tools, processing, decoration, advertising and other metal materials processing and manufacturing industries.