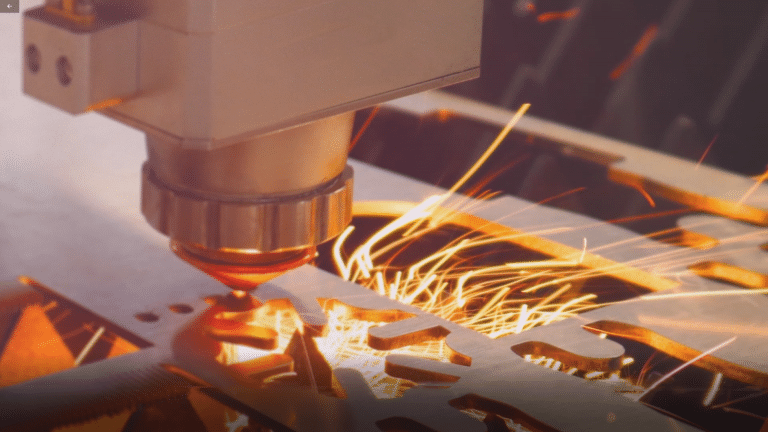

In the process of cutting metal with a laser cutting machine, various problems can occur, which seriously affects work efficiency. How should we overcome it? This post will summarize some solutions to the common problems in metal laser cutting.

Table of Contents

Solutions to Thick Metal Sheet Perforation Issue

Generally speaking, for any kind of thermal cutting technique, it is necessary to drill a small hole in the metal sheet, except for a few cases which can start from the edge of the sheet. Previously, a hole is punched out with a punch pin in the laser stamping machine, and then the laser was used to cut from the small hole.

Therefore, there are two basic methods for perforation with a laser cutter without a stamping device.

Pulse perforation

A pulsed laser with high peak power is used to melt or vaporize a small amount of material.

Air or nitrogen is commonly used as auxiliary gas to reduce hole expansion due to exothermic oxidation. The gas pressure is lower than the oxygen pressure at the time of cutting.

As an outcome of the resulting steam pressure, small particles are flung from the drilling hole. Each pulsed laser produces only a few small particles, which gradually goes deeper, so thick metal sheet perforation usually takes a few seconds.

Once the perforation is completed, the auxiliary gas is immediately replaced with oxygen for cutting.

In this way, the perforation diameter is much smaller, and the perforation quality is better than that of blasting.

The laser used for this purpose should not only have higher output power, more importantly, better beam time and space control characteristics.

In addition, pulse perforation requires a more reliable pneumatic control system to achieve gas type, gas pressure switching and perforation time control.

In the case of pulsed perforation, in order to obtain a high-quality incision, the transition technique from pulse perforation when the workpiece is stationary to constant speed continuous cutting of the workpiece should be taken seriously.

In theory, it is usually possible to change the cutting conditions of the acceleration section: such as focal length, nozzle position, gas pressure, etc., but in practice, it is unlikely that the above conditions are changed due to too short a time. In industrial production, the method of changing the average laser power is mainly adopted. The specific methods are as follows: (1) changing the pulse width; (2) changing the pulse frequency; (3) changing the pulse width and frequency at the same time. The actual results show that the (3) effect is the best.

Blasting perforation

After the material is irradiated by the continuous laser, a pit is formed in the center, and then the molten material is quickly removed by the flow of oxygen coaxial with the laser beam to form a hole. Generally, the size of the hole is related to the thickness of the plate. The average diameter of the blasting perforation is half of the thickness of the plate. Therefore, the blasting hole of the thicker plate has a larger hole diameter and is not round, and it is not suitable for parts with high requirements (such as oil mesh seam pipe), but only scraps. In addition, since the oxygen pressure used for the perforation is the same as that at the time of cutting, the splash is large.

Solutions to Generation of Burrs When Cutting Low Carbon Steel with Metal Laser Cutting Machine

According to the work and design principle of laser cutting, the following reasons are the main reasons for the burr of the workpiece:

- The focus is not in the right position, the focus position test should be performed to correct the offset

- The output power of the laser is not enough. It is necessary to check whether the laser generator works normally. If normal, check whether the output value of the laser control button is correct and adjust it accordingly.

- The cutting line speed is too slow, and the linear speed needs to be increased during operation;

- cutting

- The purity of the gas is not enough, and it is necessary to provide high-quality cutting working gas;

- The laser focus shifts, the focus position test needs to be performed, and adjust the offset accordingly.

- Instability occurs due to long-time running of the laser cutting machine, you should shut down the machine and restart it.

Solutions to Generation of Burrs When Cutting Stainless Steel and Aluminum-Zinc Plates with Metal Laser Cutting Machine

In the occurrence of this situation, you should first consider the factors that may cause burrs during the cutting of low carbon steel. However, you should not simply increase the speed, because it may result in the incomplete cutting of stainless steel and aluminum-zinc plates.

This issue is particularly serious when processing aluminum-zinc plates. In this case, comprehensive consideration should be given to other factors of the machine tool, such as whether the nozzle should be replaced, the rail movement is unstable, etc.

Solutions to Incomplete Cut of Metal Sheet

The incomplete cut of metal sheet is mainly caused by the following reasons:

- The nozzle of the laser head does not match the processing plate thickness, replace the nozzle.

- The laser cutting linear speed is too fast, reduce the linear speed;

- The nozzle sensing is not allowed to lead to the laser focus position. If the error is too large, it is necessary to re-detect the nozzle sensing data, which is easy to appear when cutting aluminum.

Solutions to Generation of Abnormal Sparks When Laser Cutting Low Carbon Steel

This will affect the quality of the cut section. In this case, if no problems with other parameters, the following cases should be considered:

- wear of nozzle in the laser head, replace it in time. In the case of new nozzle shortage, increase the gas pressure for laser cutting.

- the thread at the joint between the nozzle and the laser head is loose. In this case, stop the cutting quickly, check the connection state and screw the thread tightly.

Small Hole Deformation during Metal Laser Cutting

This is because the pulse perforation is used when machining small holes with high power laser cutting machine, which causes the laser energy concentrated in a small area, resulting in burnt of non-processed area and deformation of the hole.

In this case, change the pulse perforation (soft puncture) method to blasting perforation (normal puncture) in the processing program.

For small power laser cutting machine, pulse perforation should be adopted in the small hole processing to obtain a good surface finish.

Hope those solutions will help you solve your problems in metal laser cutting. If you have any questions, welcome to contact us for further discussion.