Table of Contents

Should I choose a fiber laser cutter or a plasma cutter?

Fiber laser cutting machine, the mechanical part of the laser cutter head has no contact with the work, and will not cause scratches on the working surface during the work.

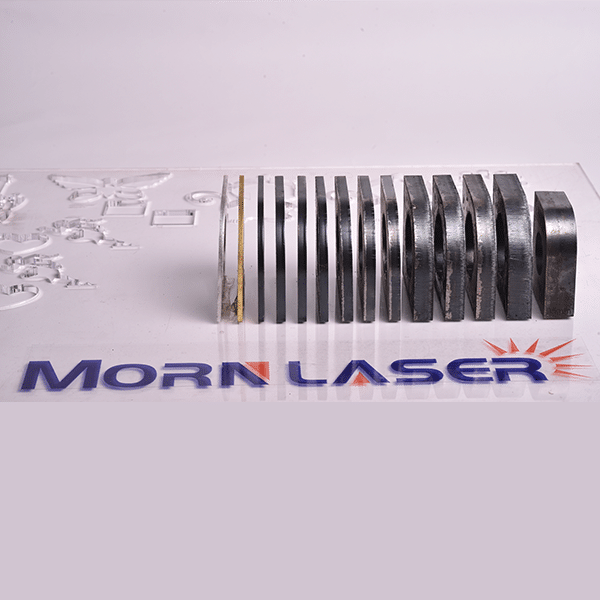

The laser cutting speed is fast, the incision is smooth and level, and there is generally no need for follow-up processing; The cutting heat affected area is small.

Adopted by the development of plasma cutting machine, working gas to plasma arc cutting properties and cutting quality and cutting speed has significant effect, the commonly used plasma arc work with argon gas, hydrogen, nitrogen, oxygen, air, water vapor, and some mixed gas, plasma cutting machine is widely used in automobiles, motorcycles, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structure and so on all walks of life.

Fiber cutting machine and plasma cutting machine compare, fiber is more expensive than plasma in the price, but the cutting quality of fiber is better than plasma, the two machines are used to cut metal, both belong to the metal cutting machine.

Compared with plasma

1, plasma cutting machine surface rough, cutting thick plate has advantages, and the price is low.

2, laser cutting smooth cutting surface, plasma is rough, need to send someone to repair burr. Laser cutting surface smooth, compensation of small precision is relatively high, expensive. In terms of cost, plasma is about a third cheaper than laser.

- The disadvantage of plasma is the slit width, which is about 3mm. The most important part of the plasma is the power supply, which is equivalent to the laser cutting machine. The power consumption of the plasma is quite severe, and the electrode protection of the riser is also quite expensive, especially the electrode hole is very expensive.

- Plasma is often used for cutting thick plates, while optical fiber laser cutting machine is often used for cutting thin plates. Plasma cutting needs to send workers to repair burrs, while laser cutting can be molded once. No secondary processing is required.

Laser cutters and plasma cutters are distinguished in detail

1, laser cutting compared with plasma cutting, laser cutting is much more precise, the heat affected area is much smaller, the slit is much smaller;

- If you want precise cutting, small slit, small heat affected area and small plate deformation, it is recommended to choose laser cutting machine;

- Plasma cutting takes compressed air as the working gas and high-temperature and high-speed plasma arc as the heat source to partially melt the metal being cut and blow away the melted metal with high-speed air flow to form cutting;

- Plasma cutting has a large heat-affected area and a wide slit, so it is not suitable for cutting thin plate, because the plate will be deformed by heat;

- Cutting speed: 1000W laser cutting 2mm thick low carbon steel plate, cutting speed up to 600cm/min.

The plasma cutting speed is slow, the relative accuracy is low, more suitable for cutting thick plate, but the end face has slope.

- Cutting accuracy: The laser cutting incision is thin and narrow, the cutting seam is parallel to both sides and perpendicular to the surface, the size accuracy of cutting parts can reach ±0.2mm.

- Contrast of slit width: Laser cutting is more precise than plasma cutting. The slit is smaller, about 0.5mm.

Plasma cutting slit is larger than laser cutting slit, about 1-2mm.

We believe that in the future development, laser cutting is the absolute world in metal thin plate, including non-metal cutting will be laser cutting will occupy a considerable part of the market.