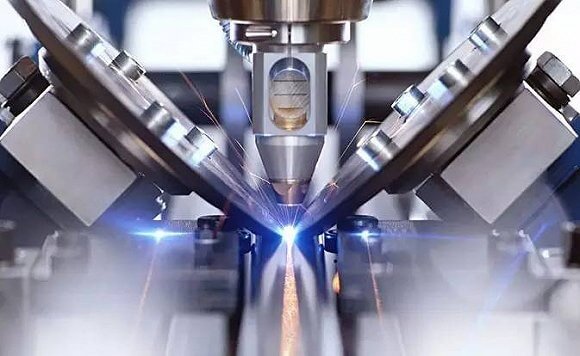

As one of the more popular cutting technologies, laser tube cutting has now been widely used in the processing of fitness equipment. Compared with the traditional tube cutting process, laser tube cutting machine has high processing flexibility and can be customized for different tubes. Also the quality and efficiency are greatly improved compared with the traditional process.

The rapid increase in demand for sports and fitness has also driven the demand for more fitness equipment in terms of quantity and quality. Due to the large amount of pipe processing in the fitness equipment industry, such as spinning bikes, bicycles, sit-ups, children’s scooters, outdoor fitness equipment and other products, all those involve a lot of pipe parts, pipe cutting and punching processes.

Pipe cutting and drilling processes are often needed in manufacturing that fitness equipment. Since many joints are connected in intersecting lines. The traditional processing method such as band saws, drilling machines, and special milling machines can not guarantee its aesthetic appearance and guarantee accuracy, furthermore, it also takes up a lot of manpower cost and time cost of tool material clamping and transfer.

Therefore, the advantages of tube laser cutting machine are gradually highlighted:

- High precision: The traditional pipe cutting is done manually, so each part of the cut is different, and the pipe laser cutting machine uses the same set of fixture system, which is processed and designed by programming software, and the multi-step processing is completed at a time, with high precision .

- High efficiency: The tube laser cutting machine can cut several meters of tube in one minute, which is hundreds of times that of the traditional manual method, which means that the laser processing is highly efficient.

- Flexibility: The tube laser cutting machine can flexibly process various shapes, which allows designers to carry out complex designs, which is unimaginable under traditional processing methods.

- Batch processing: The standard tube length is 6 meters, and the traditional processing method requires very cumbersome clamping, and the tube laser cutting machine can easily complete the positioning of several meters of tube clamping, which makes batch processing a may.

As the pioneer and leader of China’s laser industrialization application, MORN LASER laser has strong R & D strength, and has achieved remarkable results in the industry. The company’s sales network covers key industrial areas across the country and vigorously expands the international market.

In 2020, MORN LASER will continue to increase product research and development, accelerate the upgrade speed, and is committed to providing global users with high-quality products, efficient services and comprehensive laser industry solutions.

As a rising star of laser applications, the sports fitness equipment manufacturing industry has an urgent need for tube laser cutting machines. The tube laser cutting machine can complete the cutting, drilling and contour cutting of various traditional or special-shaped tubes such as round tubes, square tubes, elliptical tubes and D-shaped tubes. Limitation and the cut section of the pipe does not require secondary processing, and can be directly welded, which greatly shortens the production space. The tube laser cutting machine has promoted the transformation of the sports fitness equipment manufacturing industry, and has also opened up an emerging market for the South China Sea!

Products Recommended

Laser pipe cutting machine

- New pipe processing technology, replacing traditional sawing and punching technology;

- Fully automatic, high-efficiency and cost-effective professional pipe cutting equipment;

- It can perfectly cut round tubes, elliptical tubes, square tubes, and rectangular tubes. At the same time, angle steel, channel steel, and rhomboid tubes can also be cut through special clamping;

- Equipped with wireless control box, convenient for remote operation

The diversity of fitness equipment also puts forward high requirements for processing. A variety of specifications and shapes make traditional processing appear to be complicated and inefficient. Fitness equipment companies should closely follow the market development situation, improve production technology, strive to improve product quality, and enhance product market competitiveness.