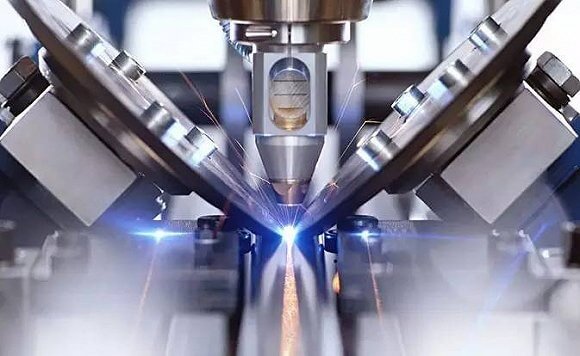

The fiber laser cutting machine will generate a lot of heat when processing sheet metal parts. Under normal circumstances, the heat generated by cutting will diffuse into the processed sheet metal along the slit to get sufficient cooling.

In the metal fiber laser cutting machine, the outside of the hole can be fully cooled, but the small hole inside the single hole has a small space for heat diffusion and the heat energy is too concentrated, which causes overburning and slagging. In addition, in the cutting of thick metal, the molten metal accumulated on the surface of the material and the accumulation of heat generated during the piercing will cause the auxiliary airflow to be turbulent and excessive heat input, which will cause overburn.

Table of Contents

How to solve the problem of burning edge and slagging

The solution to overburn when cutting carbon steel small holes with fiber laser cutting machine: In carbon steel cutting with oxygen as the auxiliary gas, the key to solving the problem lies in how to suppress the generation of oxidation reaction heat. It is possible to use auxiliary oxygen during perforation and switch to auxiliary air or nitrogen to cut after the delay. This method can process small holes up to 1/6 thickness.

The pulse cutting conditions of low frequency and high peak output power have the characteristics of reducing heat output, which helps to optimize the cutting conditions. Setting the conditions to a single pulse laser beam, high peak output with high energy intensity, and low frequency conditions can effectively reduce the accumulation of molten metal on the surface of the material during the perforation process and effectively suppress heat output.

The solution in fiber laser cutting aluminum alloy and stainless steel cutting: In this type of material processing, the auxiliary gas used is nitrogen, and there will be no burnt edges during cutting. However, due to the high temperature of the material inside the small hole , The slagging phenomenon on the inside will be more frequent. An effective solution is to increase the pressure of the auxiliary gas and set the conditions to pulse conditions with high peak output and low frequency. When the auxiliary gas uses air, it is the same as when using nitrogen. It will not overburn, but it is easy to slag on the bottom. The conditions need to be set to high auxiliary gas pressure, high peak output, and low frequency pulse conditions.

Influencing factors of laser cutting surface roughness

The surface roughness of laser cutting mainly depends on the following three aspects:

①Intrinsic parameters of the cutting system, such as spot mode, focal length, etc.;

②Adjustable process parameters during cutting, such as power size, cutting speed, auxiliary gas type and pressure, etc.;

③The physical parameters of the processed material, such as the absorption rate of the laser, the melting point, the viscosity coefficient of the molten metal oxide, and the surface tension of the metal oxide. In addition, the thickness of the workpiece also has a great influence on the surface quality of laser cutting. In contrast, the smaller the thickness of the metal workpiece, the higher the cut surface roughness level.

In order to obtain a better surface quality level, process parameters such as laser power and cutting speed must be optimized many times. Generally speaking, for materials with the same characteristics and thickness, the process parameters have a set of optimal cutting process parameters. Different cut surface qualities will also be obtained. Metal materials have low melting point, high thermal conductivity, low melt viscosity, and low surface tension of metal oxides. It is easy to obtain high surface quality during laser cutting.

It is easy to measure the surface quality of the laser cutting machine flat plate, but it is difficult to directly measure it when performing fine processing or cutting some complex patterns. The surface quality can only be controlled by optimizing the test parameters. Therefore, in order to facilitate automatic cutting, the corresponding relationship between the external optimization parameters and the surface quality level should be established.