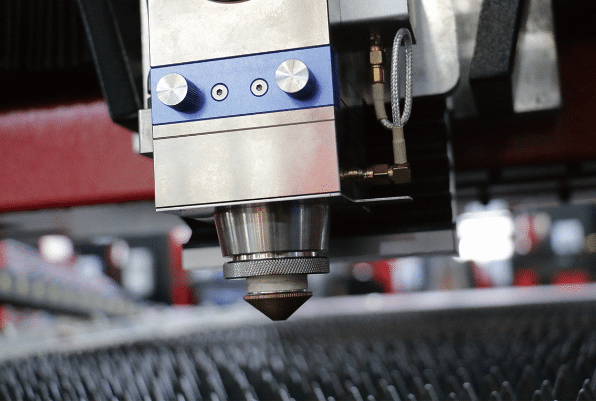

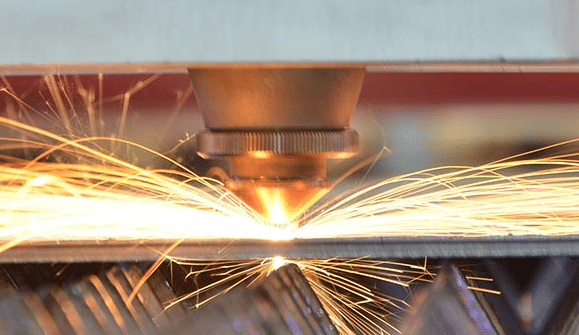

As the core component of the fiber laser cutting machine, the cutting head is a laser output device, which is composed of a nozzle, a focusing lens and a focusing tracking system. In order to ensure the normal operation of the fiber laser cutting machine, cleaning and maintenance of the laser head have become the top priority. The following is the daily cleaning and maintenance steps of the fiber laser cutting machine cutting head organized by MORN LASER for you.

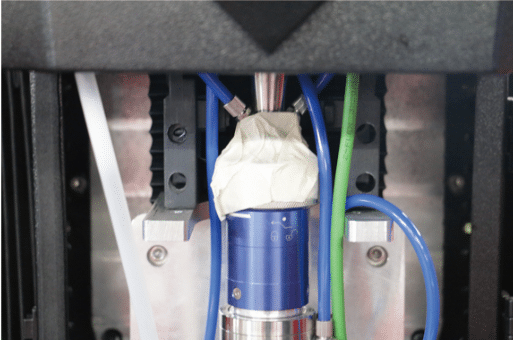

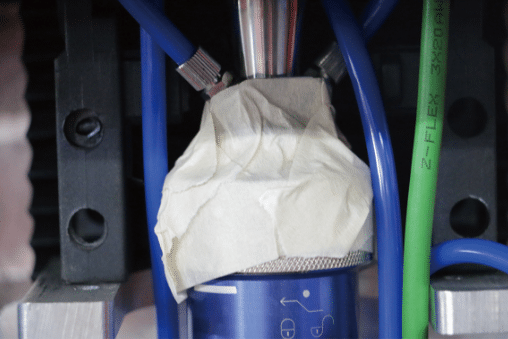

- Cutting head Sealing

In order to prolong the service life of the cutting head, after the installation and commissioning of the equipment, the upper part of the cutting head can be sealed with masking tape.

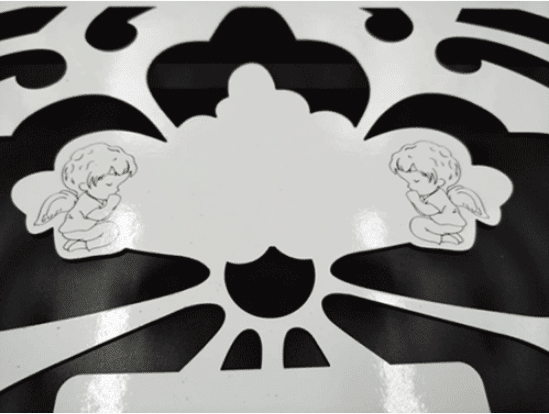

- Calibrate laser to the center the nozzle

Check whether the laser is emitted from the center of the nozzle before use every day. If not, please calibrate again and adjust the laser to the center of the nozzle.

If the light is not in the center, it will cause unstable cutting and generate burrs on the edge.

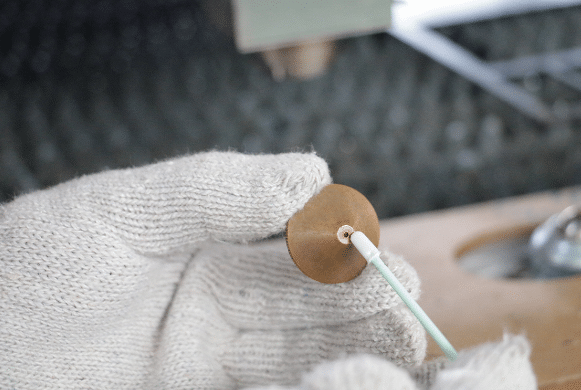

The adjustment method is to a stick transparent tape on the light outlet of the nozzle, and then emit the laser to see if the spots are offset, remove the transparent glue, as shown in below figure.

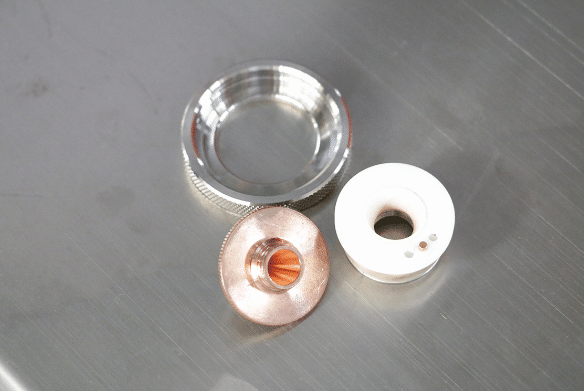

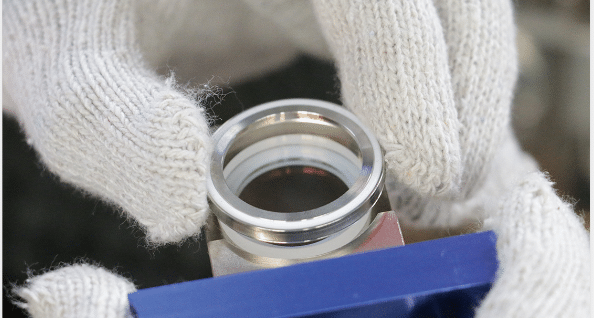

- Check ceramic ring and the nozzle

Check the roundness and cleanliness of the ceramic ring and the nozzle before each cutting. If there is foreign matter, clean it with a cotton swab and isopropyl alcohol.

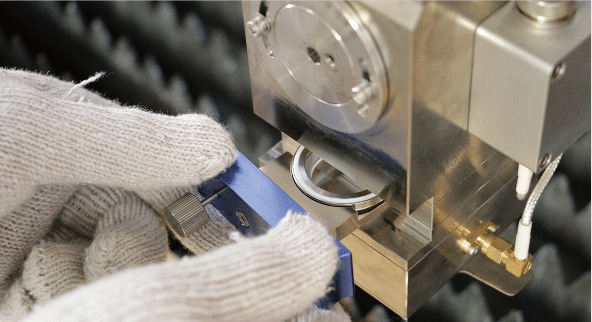

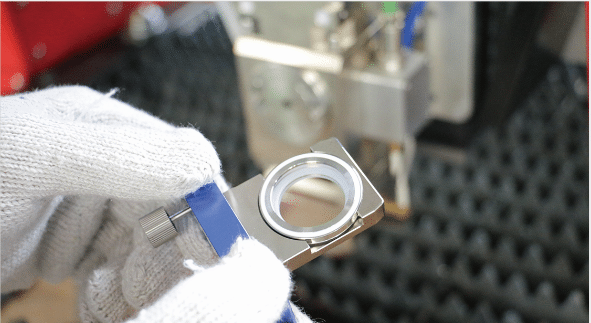

- Check the protective lens

Check the protective lens to see if it is dirty or if water mist appears. Use a cotton swab dipped in isopropyl alcohol or analytically pure (more than 99.5%) to wipe it, make sure there is no trace of water.

Warm reminder of MORN LASER: fiber laser cutting machine must be maintained regularly in order to better display its performance and use for a longer time.