Table of Contents

1. Installation of optical fiber laser cutting equipment

1.1 Preparation before equipment installation

- Communication before equipment arrival. In order to successfully complete the installation and debugging of optical fiber laser cutting equipment, the manufacturer’s technical personnel need to communicate with the customer in advance. Preparations include:

ⅠSilt requires the customer to contact the forklift or train of the corresponding tonnage of the equipment in advance to prepare for the arrival and unloading of the machine. The customer needs to arrange a person to track and participate in the training, including machine arrival inspection, machine installation, machine operation debugging, machine maintenance and matters needing attention, etc

Ⅱ Customers need to prepare the purity of 99.9% oxygen, purity of 99.99% nitrogen or clean oil-free air, and other air sources (the higher the gas purity, the better the cutting quality), for the convenience of the machine debugging and use.

Ⅲ Customers will often process or plan to process the thickness of the stainless steel or carbon steel plate ready, easy to machine debugging, and cutting use.

Ⅳ The customer needs to book the installation location of the machine in advance to facilitate the installation of the machine.

Ⅴ Customers are required to prepare 2 barrels or about 40 L of pure water, plasma water or distilled water for easy installation and use of the machine.

Ⅵ The machine needs to be effectively grounded. The customer should book the grounding device or place in advance to facilitate the installation of the grounding wire.

Ⅶ The customer needs to prepare the electronic layout of relevant cutting graphics in advance, so as to facilitate the use of the debugging sheet.

Ⅷ The customer should prepare relevant lubricating oil in advance. It is recommended to use the Great Wall heavy load vehicle gear oil 90 GL-5, check the lubricating oil amount regularly, and add lubricating oil in time.

Ⅸ The customer needs to prepare the power supply and decide the type of circuit breaker according to the power of the equipment.

- Personnel organization and training. Optical fiber laser cutting equipment is expensive, during its first installation and commissioning, it should cooperate with relevant technical engineers for installation and commissioning. Units that need to install equipment should make careful preparations before the engineer arrives, so as not to affect the installation and debugging schedule. The work includes:

ⅠThe operator of optical fiber laser cutting equipment needs to be carefully selected. In the selection process, according to the operation skills of the personnel, CNC operators should be selected and equipped with good knowledge of numerical control, flexible and agile reactions, and a sense of responsibility.

ⅡThe main responsibilities of the equipment monitoring personnel are to prepare and implement plans and measures to prevent damage that may be caused by the laser beam; The setting and management of the laser control area, the control of device operation keys; Equipment inspection, maintenance, and service record keeping.

ⅢConduct safety education on the equipment.Basic knowledge of laser, dangerous voltage, and other related knowledge, and after a complete machine operation training. The appointment of equipment operators should also be considered thoroughly. The equipment operators should be appointed by the laser equipment monitoring personnel, have the basic knowledge of hazard handling, laser, and dangerous voltage, and other relevant basic knowledge, and have been fully trained in machine tool operation.

1.2 Installation process of optical fiber laser cutting equipment

– When installing optical fiber laser cutting equipment, mechanical equipment such as crane or forklift should be appropriately applied to it. At the same time, personnel installing optical fiber laser cutting equipment should also make careful planning and preparation for installation and debugging.

– Main procedures for installing optical fiber laser cutting equipment:

- Arrange customer service personnel in advance to coordinate the pre-burying work of the machine foundation according to the actual situation, and communicate with customers to carry out foundation construction according to the foundation drawings.

- Carefully check the appearance of the equipment after its arrival the deformation of gold, and the equipment parts to check, after confirmation can be signed to the logistics personnel.

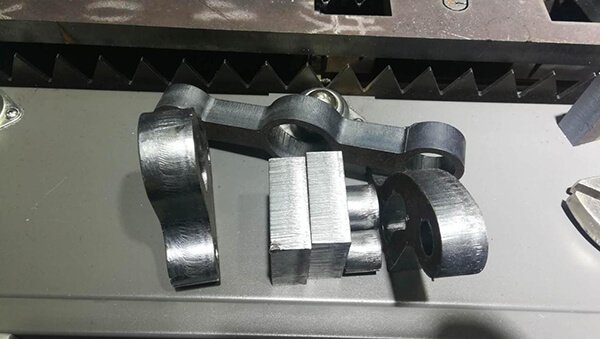

- After the acceptance of the equipment foundation, place and install the pad or the floor. Most of the installation of the pad requires welding.

- Lift the equipment or use the forklift to adjust the equipment and position it accurately.

- Install the foot and fix it by secondary welding after adjusting the level.

Once you have completed the above steps, you are ready to debug.