Due to the popularity of the metal laser cutting machines, the competition among metal processing fabricators becomes more and more intense, resulting in a decrease in the profitability of the metal laser cutting machine.

Then how to reduce the metal laser cutting cost becomes pretty urgent under the background that the whole fabrication industry needs to transform and upgrade. Metal fabricators should focus their investment on more value-added production processes such as process improvement, efficiency improvement and R&D.

This article will explore the selection of auxiliary gases for metal laser cutting with a purpose to reduce the metal processing cost. Let’s dive into the details.

Table of Contents

Why use auxiliary gas in metal laser cutting?

The use of auxiliary gas in metal cutting has benefits as following:

- Blow away the slags in the coaxial kerf;

- Cool the surface of the processed metals and reduce the heat affected zone;

- Cool the focusing lens, prevent the dust from entering the lens holder and contaminating the lens, and keep the lens from overheat;

- Some cutting gas can also protect the base metal.

Influences of auxiliary gases on metal laser cutting

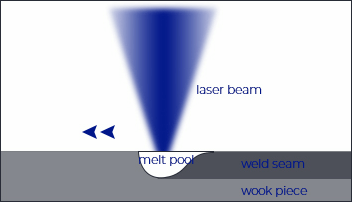

First, let’s take a look at the metal laser cutting process.

The laser generated by the vibrator passes through the lens and gathered at a point to form very tiny light spots. By precise control the distance between the lens and metal sheet, ensure the light spots is stable in the direction of the material thickness. At this time, due to the convergence effect of the lens, the light spots gather laser energy with large power density, usually, the power density can reach 106-109W/cm2. The metal absorbs the spot energy and melts at once. The use of auxiliary gas can blow the molten fluid metal away from the processed sheet and complete the cutting process.

During the whole cutting process, the auxiliary gas mainly works as the driving force to remove the metal fluid away from the sheet. Different gases have different influences on the processed metal sheet and cutting section.

O2, N2 or Air?

Assist gases include oxygen, nitrogen, air — and in rare cases, argon — and are selected based on the type of material being cut, its thickness, and the desired edge quality.

The low pressures and high speeds of oxygen make it ideal for cutting mild steel, while the inert properties of nitrogen provide a clean, precise, oxidation-free cut across all materials. But beyond these basics, metal fabricators must weigh a number of critical factors in order to choose the right assist gas for the job. Indirect labor costs, desired edge quality, gas expense, and laser power all need to be considered before making the cut.

Influences of O2 as the auxiliary gas on metal laser cutting

When O2 is adopted as the auxiliary gas, it will not only blow away the molten metal liquid, but also have an oxidation reaction which will promote the endothermic melting of the metal, so as to achieve the melting of thicker metals. This process significantly improves the processing capability of the laser.

However, due to the presence of oxygen, the cut surface of the material is obviously oxidized. Besides, it has quenching effects generated on the material around the cut surface, which improves the hardness of the metal and has a certain influence on the subsequent processing.

Influences of N2 as the auxiliary gas on metal laser cutting

When the N2 is used as the auxiliary gas, it forms a protective atmosphere around the molten metal liquid, preventing the material from being oxidized, so as to ensure the quality of the cut surface.

However, N2 has no oxidation effect to enhance heat transfer, so it does not help to improve cutting ability like O2.

In addition, the nitrogen consumption is relatively larger, which results in an increase in cutting cost compared to the use of other gases.

Influences of air as the auxiliary gas on metal laser cutting

The air consists of 78% Nitrogen and 21% oxygen.

When using air as an auxiliary gas, the oxidation of the cutting section is inevitable due to the presence of oxygen.

However, due to the presence of a large amount of nitrogen, the oxidation reaction caused by oxygen is not enough to enhance the heat transfer, and the cutting ability is not improved. Therefore, the air cutting effect is between nitrogen cutting and oxygen cutting.

The advantage is that the cost of air cutting is very low. All costs are the power consumption of the air compressor to provide air and the consumption of the filter element in the air pipeline.

Effect of auxiliary gases on metal laser cutting cost

When nitrogen is used as the auxiliary gas, the cross section exhibits a silvery luster.

While air is used as the auxiliary gas, the cross section is pale yellow.

Let’s take a 1.5 mm thick 304 stainless steel as an example to analyze the cutting cost when air and nitrogen are used as auxiliary gases, respectively, as shown in Table 1.

The model used in the comparison is the latest generation of fiber laser cutting machine equipped with a self-developed fiber laser oscillator.

Table 1 Comparison of Cutting Costs

Item | SUS304-1.5 | SUS304-1.5 |

Processing speed(mm/min) | 35000 | 35000 |

Auxiliary gas type | Air | N2 |

Air pressure (MPa) | 0.80 | 0.80 |

Auxiliary gas flow (NL/min) | 296.7 | 296.7 |

Processing time per meter(sect) | 1.7 | 1.7 |

Electricity cost(Yuan/Hr) | 14.675 | 14.675 |

Air compressor Electricity cost (Yuan/Hr) | 12.25 | 5.25 |

Auxiliary gas cost (Yuan/Hr) | 0 | 15.347 |

Subtotal (Yuan/Hr) | 26.9.25 | 35.272 |

Electricity cost (Yuan/m) | 0.012 | 0.012 |

Air compressor Electricity cost (Yuan/m) | 0.006 | 0.002 |

Auxiliary gas cost (Yuan/m) | 0 | 0.015 |

Total (Yuan/m) | 0.018 | 0.029 |

Note:

- In the above cost analysis, the operation ratio of the machine tool is calculated by 70%, and the electric charge is calculated at 1 Yuan/kW. The N2 cost is calculated according to the liquid N2 cost: 1.5 yuan.

- When cutting with air, the power consumption of the air compressor is calculated according to the constant screw air compressor of 17.5kW, 1.26MPa and 2.3m3/min.

- When cutting with N2, the air compressor is still required to supply air to the machine, thus it will also generate electricity cost.

According to the above cost analysis, when cutting with air as an auxiliary gas, the cutting cost per hour can be reduced by 23.7% compared with the use of nitrogen.

The calculation is as below:

Cost reduction=(N2-air)/N2=≈23.7%

This cost decrease can contribute a lot in reducing the overall processing cost of the factory. Furthermore, the power consumption of the air compressor is analyzed on the basis of a constant speed screw compressor.

If permanent magnet variable frequency screw air compressors are used, the power consumption of the compressors can save 50%. The cutting cost of using air can be reduced by 36.2% compared to the use of nitrogen.

Application Range of Air as Auxiliary Gas

- Carbon steel plate/Q235

When cutting with air, if the metal thickness exceeds 1.5mm, there may be burrs produced at the cutting section, but the generated burrs are not sharp enough to scratch the paper during the papering test. What’s more, for different laser powers and different types of vibrators, the maximum thickness with air cutting varies.

- Stainless steel plate / SUS304

When cutting stainless steel plate with air, the cut section produces a yellow oxide layer.

- Aluminum plate/A1050 and aluminum alloy plate/5052

The cutting burrs will be reduced compared to nitrogen cutting.

Table 2 Maximum Thickness of the Plate with Air/O2 Cutting

Material type | 4kW CO2 laser cutting machine | 4kW fiber laser cutting machine | |

Carbon steel plate/Q235 | Air | 3mm | 3mm |

O2 | 20mm | 22mm | |

Stainless steel plate / SUS304 | Air | 3mm | 3mm |

O2 | 12mm | 18mm | |

Aluminum plate/A1050 | Air | 6mm | 2mm |

O2 | 6mm | 8mm | |

Aluminum alloy/ 5052 | Air | 6mm | 2mm |

O2 | 10mm | 16mm | |

Influences of air on cutting quality of carbon steel, stainless steel, aluminum, aluminum alloy

- Carbon steel plate

When using air as the auxiliary gas, the cutting section of the workpiece may appear small burrs, however, those burrs are not sharp, thus, it can be applied to part cutting which has large tolerance for burrs.

- Stainless steel plate

Since air acts as an auxiliary gas, the metal will be oxidized after processing, and the oxide will cause defects such as slags and pores in the weld bead during welding, which will affect the quality of the weld and lead to a decrease in the strength of the welded portion. Therefore, it is necessary to polish the oxide layer of the welded portion to improve the welding quality if the air is used as the auxiliary gas to complete the cutting of the parts. In addition, if it’s an outer part, there may be some influences, since the cutting section will be oxidized, resulting in a yellow oxide layer.

The oxide layer also has an effect on the soldering, and the oxide layer must be ground before the soldering operation can be performed.

The oxide layer also has an effect on the soldering, and the oxide layer must be ground before the soldering operation can be performed.

- Aluminum plate/A1050 and aluminum alloy plate

It can reduce the cutting burrs using air as an auxiliary gas to cut Aluminum or Aluminum alloy. If nitrogen is used, the cutting burrs will be larger.

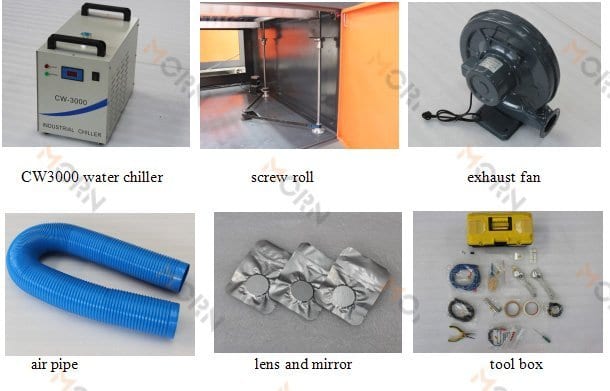

Requirements for gas supply device when using air as an auxiliary gas

When cutting with air, the air pressure needs to be 0.9 MPa.

Considering the pressure level of the air compressor produced by the manufacturer, a screw type air compressor with a rated working pressure of 1.26 MPa and a flow rate of 2.3 m3/min should be selected.

Special attention should also be paid to the quality of the compressed air to ensure that the dryness of the air reaches 99% and the moisture content is less than 1/100.

Therefore, the filter elements in the compressed air pipeline should select reliable brand products, and pay special attention to the timely replacement of the filter;

When selecting the dryer, there are two types of regenerative adsorption dryers and refrigerating dryers on the market. These two dryers have their own characteristics respectively, but if you consider long time use, less maintenance and gas supply stability, etc., it is recommended to choose a regenerative adsorption dryer.

Finally, when selecting the diameter of the compressed air pipeline and pressure reducer, the flow and pressure of the compressor output gas must be satisfied to ensure the stability of the pressure when using compressed air.

In addition, the permanent magnet variable frequency screw air compressor has now been sold in the market. Compared with the current constant speed screw air compressor, it can save 50% of electricity, which can further reduce the cutting cost.

Conclusion

In the increasingly fierce industry competition environment, increase the added value of products by improving the process difficulty of products or improving the industrial design level may be one of the means to sharpen your edge. It is also an effective way to gain competitive advantage by save processing costs under the existing process conditions.

Using air for metal laser cutting can reduce costs and bring more profits to the enterprises thus facilitate enterprise transformation and upgrading.

However, laser cutting with air is not always the best choice, before making the cut, metal fabricators must weigh a number of critical factors in order to choose the right assist gas for the job. Indirect labor costs, desired edge quality, gas expense, and laser power all need to be considered.

Choosing wisely means considering the application from setup to finished piece. Think about how the part is going to be used, and then choose the assist gas based on that.