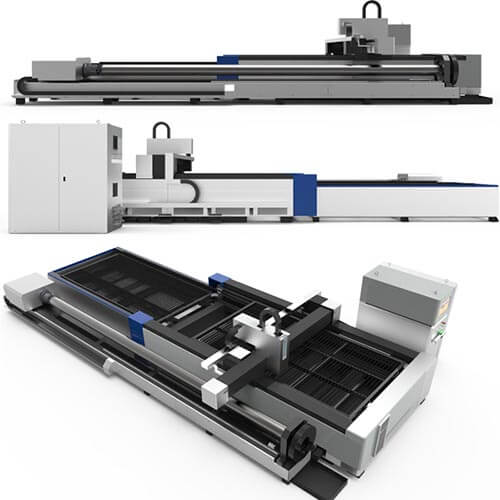

MORN LASER often visits the customer site to overhaul the laser cutting machine from time to time, to see whether the laser cutting machine is normal, which parts need to be repaired, and whether the cutting head is still at the normal calibration level, etc. The damaged laser cutting machine of the parts can be directly and obviously manifested, but it is difficult to judge whether the laser cutting head is within the normal calibration level, so what methods can we find out?

Table of Contents

1. Stability

As the most precise part of the fiber laser cutting machine-fiber laser, its performance is stable, and the service life of key components can reach 100,000 hours, so the output is very stable and does not appear deviation during the working process. When the laser is not very stable for a certain period of time and there is a small problem in the output, it can be judged with a high probability that it is not within the calibration level, and then it can be overhauled.

2. Verticality

For the fiber laser cutting machine, when the program is programmed, the cutting head will complete the cutting task according to the instructions of the program, so there will be no deviation in verticality. The verticality of the cutting edge is very important. The cutting edge deviates from the place specified by the program instruction, so that the cutting prototype does not meet the actual demand.

3. The width of the slit

The laser cutting machine is focused into a small spot, so that the focal point can reach a high power density. The material is quickly heated to the degree of vaporization, and evaporates to form a hole. As the beam and the material move relatively linearly, the hole continuously forms a width Very narrow slit. The above can meet this requirement under normal circumstances, but when the laser head calibration fails, satisfactory narrow slits cannot be cut out and the entire line is not on a horizontal line.

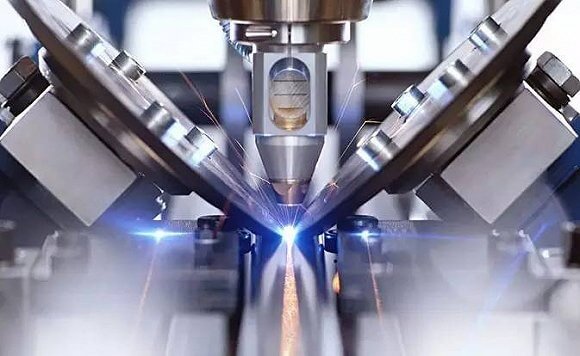

4. Coaxiality judgment

During the calibration process of the fiber laser cutting machine, if the center of the airflow and the center of the beam are not on the same axis, the sparks will sputter unevenly in all directions when cutting the carbon steel plate. Carry out the carbon steel plate drilling test again to observe whether the spark sputtering is uniform, and if it is not uniform, make adjustments. After many repetitions, the coaxiality of the air flow center and the beam center will be adjusted to an ideal state.

5. Roughness.

The laser cutting section will form vertical lines. The depth of the lines determines the roughness of the cut surface. The shallower the lines, the smoother the cut section.

6. Grain

When cutting thick plates at high speed, the molten metal will not appear in the cut below the vertical laser beam, but will spray out at the rear of the laser beam. As a result, curved lines are formed on the cutting edge, and the lines closely follow the moving laser beam. In order to correct this problem, reducing the feed rate at the end of the cutting process can greatly eliminate the formation of lines.

In addition to the above, there are many phenomena that can determine whether the fiber laser cutting machine is calibrated, such as verticality, etc., regardless of which problem is determined, you should report for repair in time to avoid unnecessary losses.