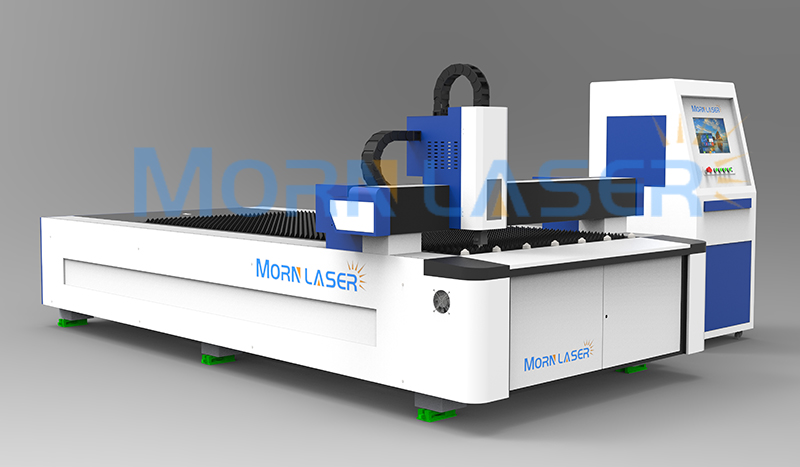

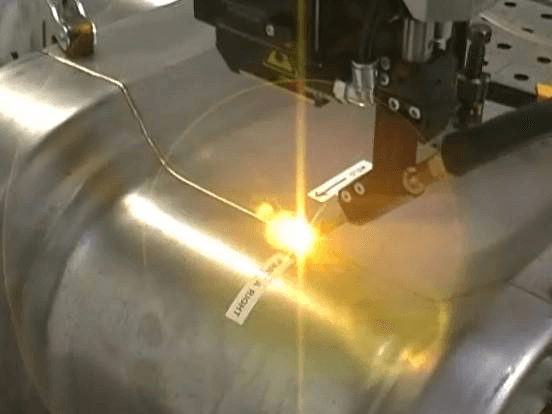

Fiber laser cutting machine is a kind of laser cutting method that uses a fiber laser generator as the optical source. Fiber laser is a new type of laser beam that is newly developed in the world. It outputs a high-energy-density laser beam which focuses on the surface of the workpiece, melting and vaporizing the area illuminated by the ultra-fine focal spot. Then the spot is moved by the numerical control mechanical system to achieve automatic cutting with high speed and high precision.

For beginners who are new to the fiber laser cutting machine, they will be in trouble when encountering poor cutting quality. How to adjust the machine in the face of numerous parameters? Let’s have a look at the solution!

The parameters that can affect the cutting quality mainly include: cutting height, cutting nozzle model, focus position, cutting power, cutting frequency, cutting duty cycle, cutting pressure and cutting speed. Hardware conditions include: protective lens, gas purity, sheet metals quality, focusing mirror and collimating mirror.

In the case of poor cutting quality, it is recommended to conduct a general inspection on the fiber metal cutting machine first. The main inspection content and orders are:

- Cutting height

The actual cutting height is recommended to be between 0.8-1.2mm. If it is not accurate, calibration is required.

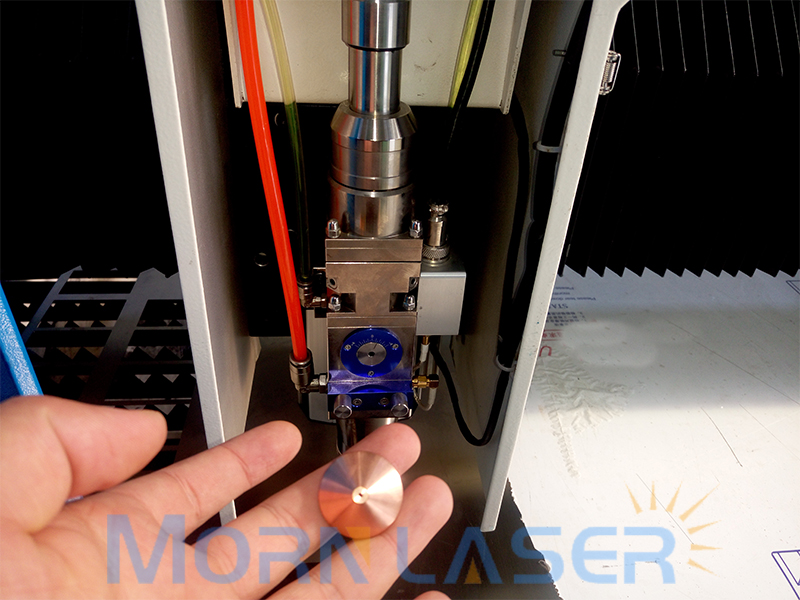

- Nozzle inspection

Check whether the nozzle model and size are wrong. If it is correct, check if the cutting nozzle is damaged, or if the roundness is normal.

- Optical center

It is recommended to use a cutting torch with a diameter of 1.0mm for optical inspection. When checking the optical center, the focus is preferably between -1 and 1mm. The light spot thus produced is small and easy to observe.

- Protective lens

Check whether the protective lens is clean and free of water, oil and slag. Sometimes the lens is fogged because of the weather or the cold auxiliary air.

- Focal point

Check whether the focal point is set correctly. If it is an auto-focusing cutting head, be sure to check if the focus is correct.

After the above 5 items are checked and there are no problems happening, the parameters should be modified according to the cutting effect.

How to adjust the parameters according to the cutting effect? We will talk about this question in the next post. No matter you are a beginner or an experienced fiber laser metal cutter operator, cutting quality is always a key point that relates to your business productivity and profit margins. At MORN LASER, we are specialized in providing efficient and cost-effective laser cutting solutions for you.

For more information on our professional laser engraving & cutting solutions based on a wide variety of materials, please pay close attention on our posts or write to technic09@morntech.com to get quick response.