Over the past decade, fiber lasers have revolutionized industrial materials processing because of their unique combination of performance, reliability, and cost advantages. Fiber laser sources have displaced many traditional metal cutting methods in existing applications, and they have made possible new applications that could not be addressed with previous technologies. One of the outstanding applications is that fiber laser cutting machine is capable of processing reflective metals with favorable results.

What are reflective metals?

“Highly reflective metal” is a common word that almost all metal processing practitioners know. But what it means in essence? To figure out what is reflective metals, firstly it is important to know the constituents of metals. Take Aluminum and Silver as examples, they are highly reflective and can reflects 95% visible light. Laser cut and marked aluminum and silver products are widely used in windows, jewelry, solar mirrors, decorative materials. Other reflective metals like gold, bronze, copper and brass are also hard to laser cut using fiber lasers. Stainless Steel is also considered to be a reflective metal especially when an object made of steel is given a mirror polish. All these reflective metals have to be processed by fiber laser sources.

How to cut reflective metals?

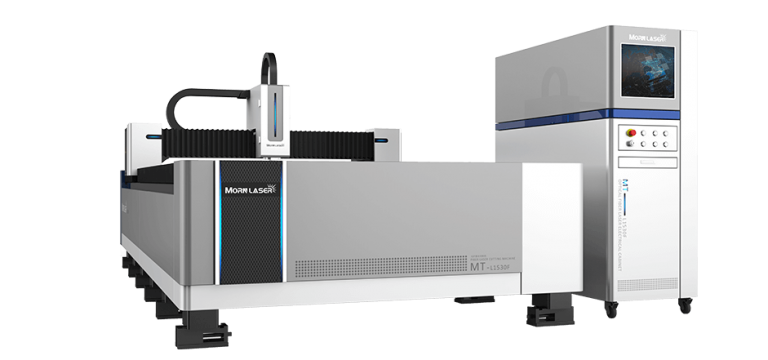

Laser processing on reflective metals needs special fiber laser sources. As the reflected beam will damage the laser machines, nLIGHT fiber laser source is adopted by MORN® fiber laser metal cutters to cut reflective metals. Fiber lasers are the most modern, swift and cost effective way to cut thin reflective metal sheets. As these lasers do not use mirrors and delicate lenses, the reflection from metals like copper, aluminum and brass do not damage the cutting equipment. So Fiber laser technology is the best way to cut reflective metals.

Advantages of MORN® fiber laser cutter for reflective metal sheets:

- Stable processing of polished stainless steel, aluminum, brass, and copper: nLIGHT fiber lasers are especially configured on our fiber laser cutting machine specializing in cutting high reflective sheet metals. This fiber laser source incorporates a proprietary back-reflection isolator that protects all modules from back-reflections generated by the workpiece. The whole cutting process is safe and stable, without any damage to the laser source.

- Highest uptime with the lowest cost of ownership: our fiber laser metal cutting machine design enables end users to manage maintenance and service regularly, which results in higher machine uptime, lower cost of ownership, and a greatly improved customer experience.

- Improved cutting performance: our fiber laser metal cutting machines are designed for precision metal parts manufacturing industries. Featured with faster processing of fine features, and better processing quality through minimal heat affected zone, they have been widely welcomed by customers. More features and advantages of our fiber laser cutters, you can read this post.

Now that you know how to deal with reflective metals, you can take up this task with ease. If there is any problem during your manufacturing process, please contact us or leave your message below. We will give quick response and professional laser solution to your questions!