Table of Contents

How can the laser cutting machine be maintained correctly?

Although high-quality after-sales service can provide some basic guarantees, regular and comprehensive maintenance is the most important thing to truly extend the service life of the laser cutting machine, so as to achieve a real low investment and high return. So how can we properly maintain the laser cutting machine?

1. Cleaning of various components

In order to ensure that the laser is always in a normal working state, after two weeks of continuous operation or when it is not used for a period of time, the components in the optical path such as the laser lens should be checked first before starting to make sure that the optical components are free from dust pollution, mildew and other abnormal phenomena , If there is any abnormal phenomenon mentioned above, it should be cleaned and cleaned in time to ensure that the optical components will not be damaged under strong laser irradiation. (If the operating environment of the equipment is relatively clean, the above inspection can be extended to one month or even longer accordingly). Details information as follows:

- Replacement of circulating water and cleaning of water chiller.

The chiller needs to use distilled or purified water, but not mineral water.

It is worth noting that in the environment of high temperature or relatively humid environment, the laser should always pay attention to observe whether there is “condensation” caused by the low water temperature on the cooling water circulating pipe or laser concentrating cavity. The phenomenon of “condensation” will cause damage to the end face of the YAG crystal, resulting in a decrease in output power and even failure to emit light. If there is “condensation”, immediately stop using the laser cutting machine. After the moisture on the surface of the concentrating cavity is naturally dried, re-check the condition of the YAG optical surface to determine whether to clean the YAG rod. Check that everything is normal before turning it on again. Pay attention to properly adjust the lower limit set temperature of the high temperature controller before starting up.

- Fan cleaning:

When the fan in the machine is used for a long time, a lot of solid dust will accumulate in the fan, which makes the fan generate a lot of noise, and is not conducive to exhaust and deodorization. Dust will also deteriorate the insulation performance of electrical components and cause electrical breakdown, which will increase the wear of the motion system, reduce the accuracy, and make the light output of the optical path system weaker or even unable to emit light. When the fan suction is insufficient, the fan needs to be cleaned. The surface of the equipment can be wiped clean with a rag, and the inside of the equipment can be flushed with a long-bristled brush and a high-pressure air gun to flush the interior clean.

3) Lens cleaning:

The protective lens on the machine is easy to be stained with dust or other contaminants, which affects the cutting accuracy and causes the loss of the laser or the damage of the lens. Generally, it is necessary to wipe the protective mirror carefully with absolute alcohol in about a week (according to the frequency of use of the laser cutting machine).

At the same time of cleaning:

- The lens should be wiped gently, and the surface coating should not be damaged;

- The wiping process should be handled gently to prevent falling;

- When installing the protective lens, be sure to keep the concave surface down;

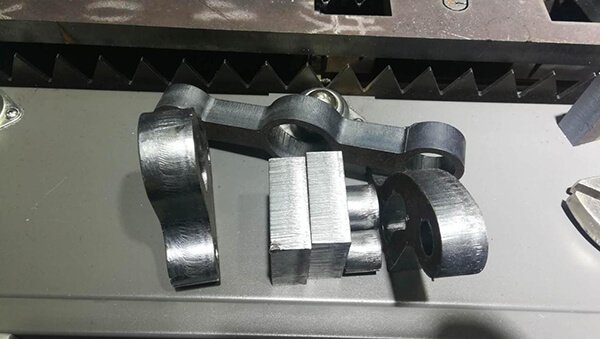

4) Guide rail cleaning:

Guide rails and linear shafts are one of the core components of the equipment. In order to ensure the high processing accuracy of the machine, the guide rails and linear axes are required to have high guiding accuracy and good motion stability. During the operation of the equipment, a large amount of corrosive dust and smoke will be generated by the processed parts, and these smoke and dust will be deposited on the surface of the guide rail and linear shaft for a long time, which will cause many adverse effects on the processing accuracy of the equipment, and will cause the Corrosion spots are formed on the surface of the linear shaft, which shortens the service life of the equipment. The machine guide rails should be cleaned every half a month, and the machine should be turned off before cleaning.

2. Fastening and lubrication of screws and couplings

After the motion system works for a period of time, the screws and couplings at the motion connection will loosen, which will affect the stability of the mechanical motion. During the operation of the machine, it is necessary to always observe whether the transmission parts have abnormal noise or abnormal phenomena, and tighten the screws one by one with tools at intervals. The first tightening should be about one month after the equipment is used.

Since the laser cutting machine is particularly sensitive to vibration, the working environment should be far away from places where there are vibration sources such as punching presses, heavy objects, etc., and anti-vibration pads can be installed to avoid environmental impact on the machine. In addition to tightening the adjusting screws, some bearings of the laser cutting machine need to be regularly lubricated (except oil-impregnated bearings). Use a clean soft cloth to wipe off the floating soil on the bearing, use a needle tube to suck the oil into the needle tube, and then use the needle to slowly inject the bearing, and then slowly rotate the bearing when filling the oil.

3. Heat protection and heat removal

An increase in temperature will reduce the insulation performance of the equipment and deteriorate the parameters of the components. It is usually stipulated that the working environment of the cutting machine should not exceed 40℃, and 20~25℃ is the most suitable.

4. The optical path needs to be checked before work

The optical path system of the laser cutting machine is focused by the mirror and the lens together or only by the lens. All the mirrors and lenses are mechanically fixed, and there is the possibility of offset, which usually does not happen when it is not working. Offset, vibration will produce slight offset during exercise, so regular inspection is required. Maintenance method: The user checks the coaxial optical nozzle before work every day to determine whether the optical path is normal. The optical mouth is coaxial once a day, and the inner optical path is once half a year.

5. The matters needing attention in the daily maintenance process

1) The suction device should be inspected and cleaned regularly, and the fan duct should be cleaned, otherwise the dust will quickly contaminate the lens and laser tube, which will easily oxidize the mechanical and electronic components and cause poor contact;

2) The power of the electricity grid needs to match the equipment itself;

- The dirt and dust on the machine body, cutting head, sensor and other parts should be removed in time to keep the appearance of the machine clean;

- The combustibles (such as glove rags, etc.) in the machine should be cleaned up in time to prevent fires during cutting;

5) The iron slag on the hopper waste car should be cleaned up in time to ensure that the cutting waste can fall smoothly;

6)Before carding the machine every day, carefully check whether the pressure of the working gas

7)and the reducing valve are working properly to avoid insufficient air pressure, which will affect the quality of the cutting section;

8)Before use, check the connection of each air pipe of the cutting head to determine whether there is leakage of cooling water to ensure the normal supply of gas and cooling water;

9)During the debugging process, a black metal material with good absorption performance should be placed on the optical path of the laser output as a beam terminator to prevent fire accidents.

Only by correctly mastering these five tips for maintaining the laser cutting machine can the laser cutting machine have a longer life, so as to truly achieve low cost and high return.