In summer, as the temperature rises, there is a gradual increase in atmospheric moisture. Summer is a season of a high incidence of fiber laser failures. According to statistical results, most failures of high-power fiber lasers are closely related to the user’s operation sequence and equipment operating environment. MORN LASER today will provide some preventive measures for your fiber laser maintenance.

Table of Contents

Preventable Failure Mechanism

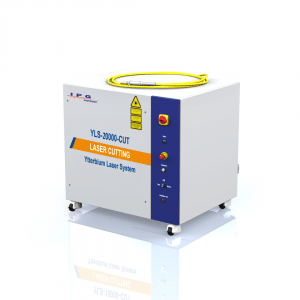

Fiber laser is a device that converts electrical energy into light energy. The internal structure is relatively complicated, involving multiple disciplines and fields such as light, machine, electricity, etc. While there are far less preventive maintenance requirements with fiber lasers, cleanliness and strict adherence to factory optic cleaning and maintenance procedures and performing those tasks in a controlled, dust-free environment are critical to a fiber’s successful operation.

Its use environment must be satisfied, and own protective measures can effectively play a protective role. If there are omissions in the boot sequence, enclosure sealing, and water temperature setting, the electronic and optical devices inside the laser that are cooled by water may cause surface condensation due to the temperature difference between the inside and the outside, thereby reducing the performance of the laser and even damaging the laser.

Scientific Preventive Fiber Laser Maintenance in Summer

Enclosure tightness

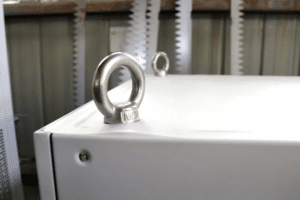

The cabinet of the fiber laser adopts a closed design, and the air conditioner or dehumidifier is installed. The purpose is to ensure that each component in the cabinet is in a relatively stable and safe temperature and humidity environment. If the cabinet is not in a sealed state, the high-temperature and high-humidity air outside the chassis can enter the interior of the cabinet. When the air meets the internal water-cooled component, condensation will occur on its surface, causing possible damage. Therefore, the following aspects should be paid attention to when checking the enclosure tightness:

It should be noted at this time:

- Whether each cabinet door exists and closes tightly;

- Whether the top lifting bolt is tightened;

- Whether the protective cover of the unused communication control interface at the rear of the cabinet is closed, and whether the protective cover that has been used is fixed.

Boot sequence

Since the fiber laser enclosure cannot be completely sealed, and the air conditioner inside will stop running when the power is turned off at night. If the room is not equipped with air conditioning or the air conditioner does not work at night, the external hot and humid air can gradually penetrate into the cabinet. Therefore, when restarting the fiber laser next morning, please pay attention to the following steps:

It should be noted at this time:

- Turn on the laser power supply (without light) and let the cabinet air conditioner run for about 30 minutes;

- Start the matching water chiller, wait for the water temperature to adjust to the preset temperature, and turn on the fiber laser switch;

- Perform normal processing.

MORN LASER reminder: If possible, under the premise of ensuring safety, keep the cabinet air conditioner running at night. Or install the fiber laser in the air-conditioned room and keep the air-conditioning continuous and stable operation (including at night).

Water temperature setting

The cooling water temperature has a direct effect on the electro-optical conversion efficiency, stability, and condensation. Normally, the cooling water temperature is set as follows:

It should be noted at this time:

- The temperature of the low-temperature water (cooling fiber laser module) should be set at around 21 degrees Celsius.

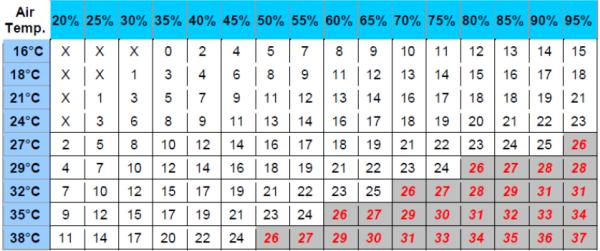

- For fiber lasers above 2500W, the temperature of DI water (cooling optics) should be set between 27 degrees Celsius and 33 degreesCelsius. This temperature should be adjusted according to the ambient temperature and humidity. Generally speaking, the ambient temperature, the higher the humidity is, the higher the DI water temperature should be. The basic principle is that the DI water temperature should be above the dew point. The dew point table is as follows:

The dew point table gives the dew point temperature (℃) according to the humidity and temperature. The cooling water must be higher than the dew point temperature to prevent condensation.

Conclusion

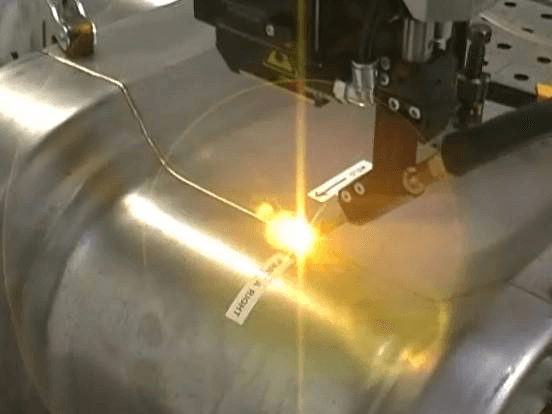

The climatic characteristics of each season are very different. The fiber laser cutting machine is a piece of relatively high-precision and expensive processing equipment. Scientific and orderly maintenance against climatic characteristics can effectively avoid small problems in the fiber laser cutting process and increase the service life of the laser cutting machine.

If you have any questions about repairs and maintenance of fiber lasers or other problems with fiber laser cutting machines. Welcome to consult our engineer. MORN LASER is dedicated to serving you.