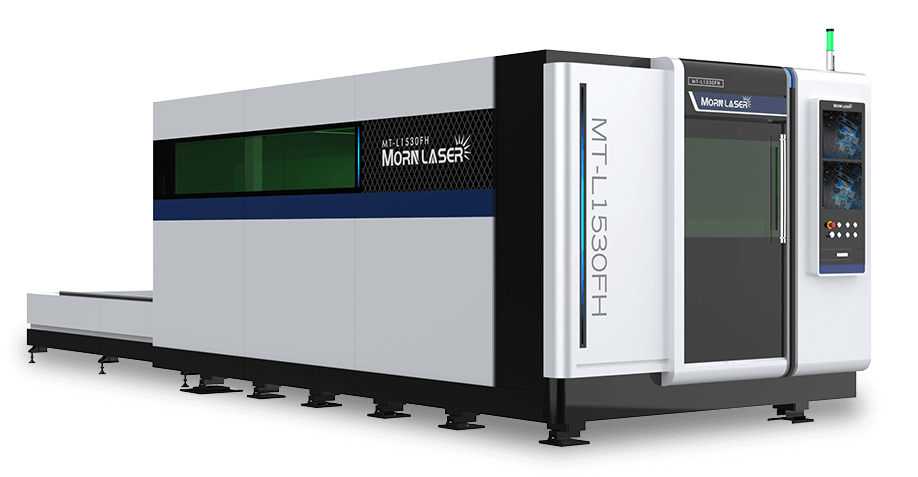

With the continuous development of the laser industry. More and more laser equipment appears in people’s lives and work. It keep ahead in market share and serve for global industries.

Fiber laser cutting machine is a laser cutting machine that uses a fiber laser generator as the source. Fiber laser is a new type that is newly developed in the world. It outputs high-energy-density laser beam, which is concentrated on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by a CNC mechanical system. Realize automatic cutting by irradiating position, fast speed and high precision.

In order to extend the service life of the machinery and maximize the efficiency of the equipment, it is necessary to process and maintain the machinery frequently. Here are some guidelines, please kindly check as below:

Table of Contents

Whole machine maintenance

—Using a cleaning veil to wipe foreign objects such as internal and external dust after get off work every day, , and the receiving trolley to clean up waste materials to maintain the overall clean and beautiful appearance of the equipment.

—Replaced the blade according to the usage (generally half a year) . In order not to affect the cutting effect and thin plate cutting, the blade material is carbon steel plate.

Cleaning and maintenance of transmission part

—Check the dust cover of X and Y axis every day for burns and damage.

—Cleaning the iron filings on the dust cover and rail rack.

—Check whether there is oil leakage from the lubricating oil pump every week, or an alarm occurs when the oil level is too low, and add lubricating oil in time.

—Cleaning the lead screw guide of the Z axis with a clean cotton swab every half month, and apply a proper amount of lubricant after cleaning.

Pneumatic maintenance

Checking the nitrogen gauge, oxygen gauge and each gas path joint every day to prevent air leakage.

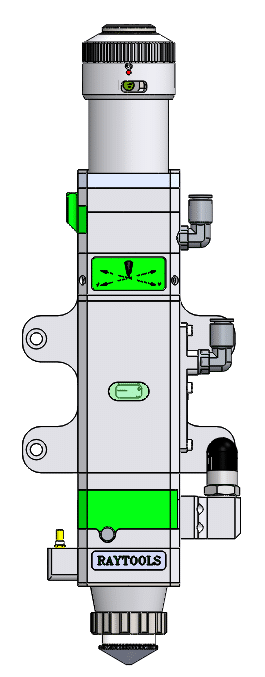

Laser head maintenance

—The protective lens module of the laser head needs to be checked daily.

—The collimation module and the focus block are inspected every three months.

Laser source maintenance

The laser source is a high-precision component and can basically be maintenance-free. Largely affected by environmental factors. Drain the cooling water every day; when the machine is in use, the water chiller is always on; add antifreeze coolant, etc.

Water chiller maintenance

—Clean the filter weekly to ensure good ventilation and heat dissipation;

—Every week, observe whether there is water leakage at the back of the water cooler and the various water connections of the bed;

—Changing the cooling water every three months:

- Open the drain, unscrew the filter and clean the filter;

- After the cooling water in the water chiller is completely drained, add pure water or distilled water to the water injection port.

Control cabinet maintenance

There are a variety of electrical components inside the control cabinet. It is recommended to remove the dust inside the control cabinet every three months. The equipment need powered off before dust removal. Do not touch any wiring terminals within 5 minutes to avoid injury. Use a clean veil to clean up various electrical devices and cables inside the control cabinet.

While doing the daily maintenance of the equipment, if any parts are damaged during the use of the machine, they must be replaced in time. This is not only a protection for the machine itself, but also to ensure that the laser cutting machine always maintains a Ideal cutting effect.