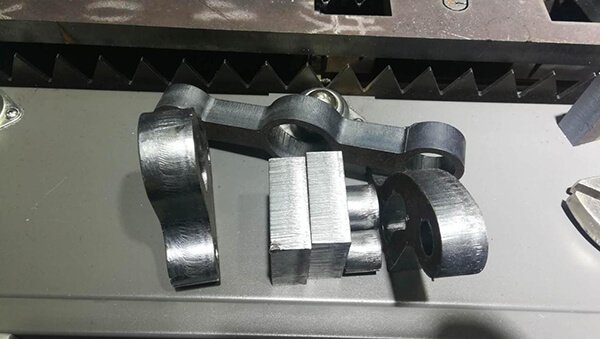

Compared with traditional cutting methods, fiber laser cutting machine has obvious advantages. Due to its high precision and obvious narrow slit effect, laser cutting adopts non-contact technology. With the development of the manufacturing industry, the quality of laser cutting is increasingly required. Especially in the aviation field, when performing 3D laser cutting on complex curved sheet metal parts, it is necessary to adjust the posture and process parameters of the laser head in real-time according to the curvature of the curved surface to ensure the cutting quality. Through the simulation system, the staff can not only intuitively grasp the laser cutting process to ensure the reliability of the processing code but also optimize some cutting process issues to ensure the cutting quality. In actual cutting, in order to meet the processing needs of different types of metal plates, various three-dimensional laser cutting platforms should be used for processing according to the size, processing accuracy, and shape characteristics of the plate. At present, the virtual site construction efficiency of laser cutting simulation software is low, platform switching is complicated, learning costs are high, the implementation of cutting traces is lacking, and the process processing module is not perfect. This article analyzes how to set fiber laser cutting machine parameters and quality control.

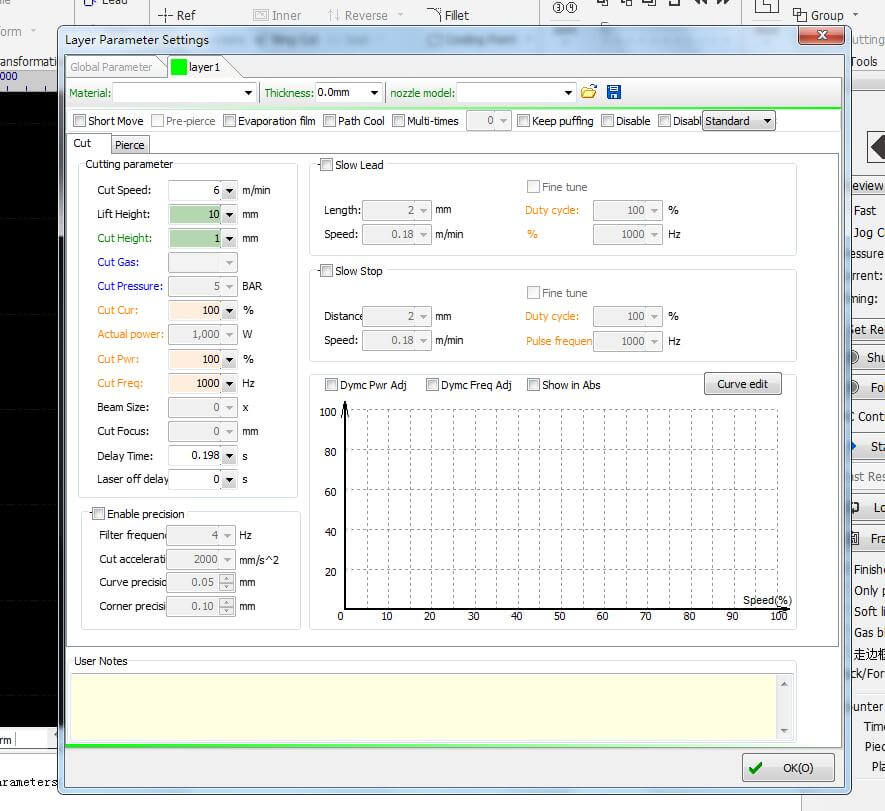

Parameter setting of fiber laser cutting machine

Fiber laser cutting machine parameters include cutting speed, power, gas cutting, etc. Laser cutting analyzes the cutting quality and cutting efficiency separately, and analyzes the impact of different types, but through the combination of laser cutting to achieve the various parameters required for the best configuration, different factories will accord the cost structure, quality and efficiency are paid special attention to and weighed to a certain extent.

Cutting speed

Laser cutting machine’s laser head can move along the part shape in unit time. The higher the laser cutting speed, the shorter the cutting time, and the higher the laser cutting production efficiency. However, when other parameters are fixed, the laser cutting speed is not linearly related to the cutting quality. Reasonable cutting speed is a range value. Below this range value, the energy of the laser beam remains too much on the surface of the part to cause excessive combustion. If the range value is exceeded, the energy of the laser beam is too late to completely melt the part material, resulting in the cut is impenetrable.

Laser power

Laser output power is the output energy of the laser system, and laser cutting represents the ability of the laser beam to melt materials per unit time.

Focus position

The laser output is finally focused on the point with the highest power density through a special lens. The focal spot diameter is proportional to the focal depth of the focusing lens. The focus of fiber laser cutting machine is set according to different thicknesses at different positions. The correct focus position is an important condition for obtaining stable cutting quality. The cutting quality of laser cutting is related to the laser beam but also related to the characteristics of the laser beam focusing system, that is, laser cutting the size of the laser beam after focusing has a great influence on the quality of laser cutting.

Gas support pressure

An incision is formed in the gap. Proper air pressure can help speed up the laser cutting speed, and the size of the auxiliary gas pressure also affects the cutting efficiency of the fiber laser cutting machine. If the thickness of the laser cutting material increases or the cutting speed is slow, the gas pressure should be appropriately reduced. Cutting with lower air pressure can prevent frosting.

Nozzle distance

The focused laser is applied to the surface of the part through a copper nozzle. The distance between the workpiece and the laser nozzle is called the distance of the nozzle. The distance from the nozzle to the part is measured based on flow and pressure. The blowing force of the gas that is too far away is too large, and the exhaust gas flow is too large, which will affect the splash. The appropriate distance is 0.8-1.0mm. Choose different types of nozzles according to different material thicknesses.

For example: 3 mm thickness material, adjust focus position -4 mm, nitrogen cutting pressure 12 Pa, nozzle distance 1 mm, fiber laser cutting machine’s power 3000 W, cutting speed 12 m/min, because various parameters are adjusted well, cutting conditions are good, and various test, when the parameters are adjusted to the most suitable condition, the cutting surface is smooth.