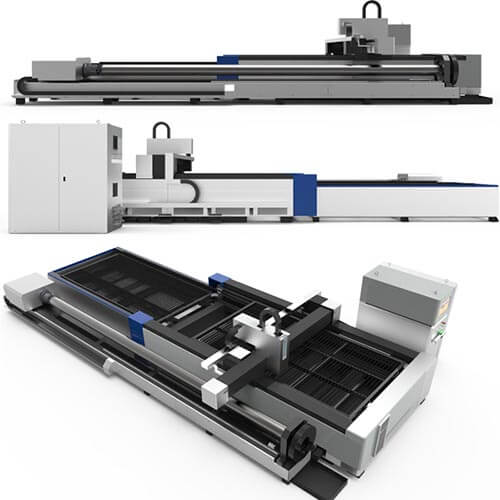

Fiber laser cutting machines have become the mainstream processing and cutting equipment due to their fast speed, high efficiency, low cost, safe operation and stable performance. The continuous on-line of its high-performance state is closely related to the setting of the cutting speed of the equipment.

Table of Contents

Harm Caused By Improper Cutting Speed

Too fast

- Unable to cut, sparks are spraying randomly

- Cause the cutting surface withstripes, andgenerate melt stain at the lower half of the surface

- Cause roughsection , but no melting stains

Too slow

- Cause over-melting condition, rough cutting surface

- The slit becomes wider and melts in the sharp corners

- Affect cutting efficiency

Factors That Affect The Cutting Speed

Material

The metal materials can be cut by the laser cutting machine include aluminum, stainless steel, carbon steel, copper, and alloy materials. Each material has its own properties, and its absorption rate of laser light is also different, so the cutting speed setting should be different.

Thickness

The thickness of the material is different, the time required for piercing and processing will be different. During the cutting process, the thicker the thickness, the greater the laser energy required and the slower the cutting speed.

Output Power

The thickness of the material is different, the time required for piercing and processing will be different. During the cutting process, the thicker the thickness, the greater the laser energy required and the slower the cutting speed.

How to Set The Cutting Speed

Before metal processing, the machine parameters must be set first. Generally speaking, if the parameters are not set well, there will be problem with the cutting speed. Pay attention to the following two points when setting parameters:

Initial velocity

The initial speed is the speed at which the machine starts, it is not the bigger the better. If the setting is too high, the machine jitter will be very large.

Acceleration

The acceleration affects the time it takes from the initial speed to when the machine normally cuts.

The machine is constantly starting and stopping when cutting different patterns. If the acceleration is set too low, it will slow down the cutting of the machine.

How To Judge Whether The Cutting Speed Is Appropriate

The cutting spark of laser equipment can be used to judge whether the feed speed is appropriate.

- If the spark spreads from top to bottom, it indicates that the cutting speed is appropriate

- If the spark tilts backward, it indicates that the feed speed is too fast

- If the sparks appear to be non-diffuse and small, and condense together, it indicates that the speed is too slow

MORNLASER

As a high-tech equipment, MORNLASER’s laser cutting machine has a good human-computer interaction interface, simple and standardized operation. But to always ensure the high-performance operation of the equipment, there are still many details and precautions.

MORNLASER has a professional after-sales service team, which can provide customers with 24/7 fast-response after-sales service, and provide customers with professional and meticulous technical support.