Table of Contents

Configuration suggestions for high power fiber laser cutting machine part A

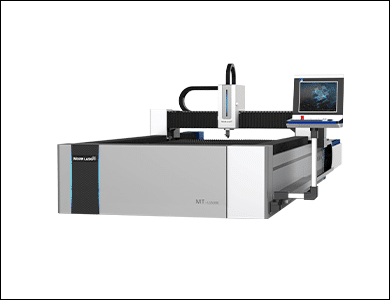

With the maturity of 10,000-watt fiber laser cutter technology, the thick sheet cutting has a better laser solution. However, some customers are not familiar with the configuration and operation of the 10,000-watt ultra-high-power fiber laser cutting machine. Therefore, today’s we will give some suggestions for selection, installation and maintenance and precautions of fiber cutting machine.

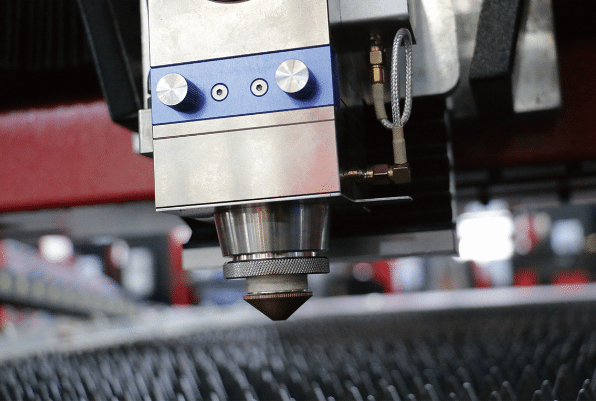

Laser head model selection

Connector model: At present, the mainstream of 10,000-watt fiber laser output head is Q+ and QD, and the cutting head should be the same when you choose it. For now we recommend you choose German Precitec brand that is more stable for fiber laser cutting machine using.

Laser head installation

Environmental requirements: clean room or clean bench above 1,000 level;

Tools: microscope with more than 100 times;

Auxiliary accessories: absolute alcohol or IPA, cleaning cotton swabs, dust-free cloth, masking tape, a full set of inner hexagon, screwdriver, utility knife;

Others:

- Before installing the head for fibre laser metal cutting, make sure that the internal cavity and lens of fiber laser cutter head are clean and the crystal and periphery of the laser output head are clean;

- The installation of the output head of the 10,000-watt fiber laser into the cutting head and the inspection of cleanliness must be carried out in a dust-free environment of more than 1,000 times, and a microscope of more than 100 times should be used for inspection.

The more details as follows:

- Ensure that the inside of the fiber laser cutting head is clean;

- Remove the metal protective cover of the laser output head;

- Fix the laser output head horizontally and aim it at the microscope;

- Clean the periphery of the laser output head;

- Remove the crystal protection ring of the laser output head;

- Adjust the microscope to make the end face of the crystal clearly visible;

- Check the entire end face of the crystal. When it is found to be dirty, wipe it clean with a cotton swab moistened with absolute alcohol;

- After ensuring that the laser output head crystal is clean, insert the output head horizontally into the cutting head;

- Lock the laser cutting head and seal the connection with tape;

- Install the cutting head to the cutting machine, move at high speed, and check whether there is dust falling on the lens through the laser red light;

- Make sure that the fiber cutting head is clean before outputting laser cutting.

Laser head maintenance

- Before using the fiber laser cutting head, it is recommended to wrap a layer of tape around the laser cutting head (use to tear off the glue without residue) to avoid dust in the gap from entering the inside of the cutting head during later maintenance;

- Once the lens inside the fiber cutter head is dirty or damaged, it is recommended to use a replacement method, and it is not recommended to take it out for cleaning to avoid secondary and more serious pollution;

- In addition to replacing the lower protection lens, the laser cutting head can be operated on the fiber laser cutting machine. The replacement of the upper protection lens and the collimating focus lens must be performed in a dust-free environment with a level of 1,000 or more;

- To check the lens of the 10,000 watt cutting head, first use white paper to check whether there are black spots in the red light of the 10,000 watt fiber laser, then output the laser at low power, check whether the spot is a little bit with black photosensitive paper, and finally take out the lens to check under a microscope.

Laser head test

- Whether the calibration of laser cutter is correct or not;

- Whether the focus adjustment is consistent with the actual focus of the monitoring;

- Whether the actual zero focus is at ±1mm focus position;

- Whether the cutting effect of different thickness and different material plates is normal;

- For long-time cutting, whether the temperature of the lens and cutting head is stable, whether there is a thermal lens in the lens, and whether the cutting effect is consistent.

The next time we will introduce more about other configuration of high power fiber laser cutting machine. Hope it can help you know the machine better. If you have any interests about laser machine, you can also contact with us directly.