Metal industry now has sprung up like mushrooms due to the high demand for metallic products and high precision equipment, such as elevators, metal advertising signage, and metal cabinets. Metal cutting, therefore, posed a rapid development period in which metal cutting machines are largely demanded accordingly. If you chance to start up your metal cutting business with a metal cutter, then you really need to think about which kind of machine is the best deal.

We believe before beginning your business, you must have investigated some relative information about metal cutting and got familiar with something about laser cutting machines, the most mainstream cutting technology in the modern metal cutting sector. After that, you may search for laser cutting machine suppliers and select your machine, in which process you may be at a loss or confront the confusing situation on how to choose the best laser cutting machine for yourself. In view of this, here we would like to offer you some guidelines to help with your selection.

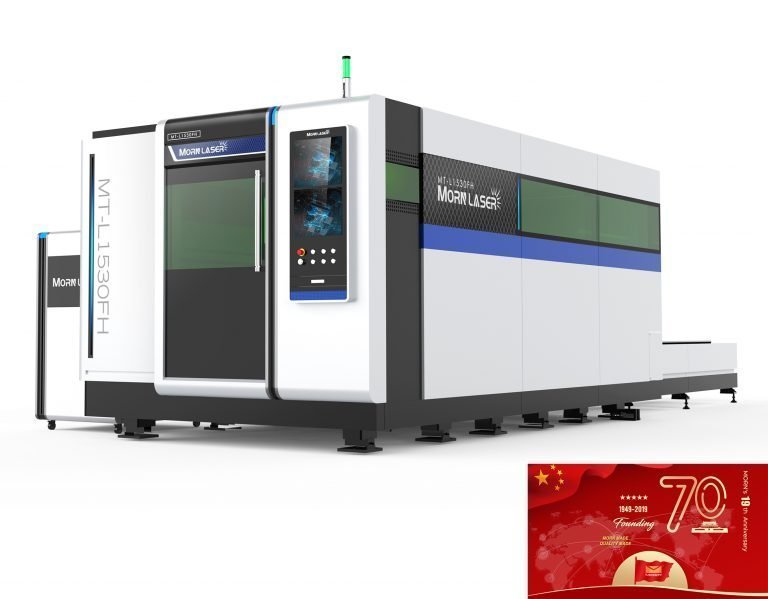

Firstly there are mainly two types of laser cutting machines in the current market: fiber laser cutting machine and CO2 laser cutting machine, except for which some other unpopular cutting machines will not be mentioned here. To make a choice between these two types, you should first make sure which metal type you want to cut, whether it’s sheet metal or thick plate, and what your budget is.

Fiber laser cutters are best for sheet metals cutting with pretty high precision and quality, and especially at a lower cost. And CO2 laser cutting machines are the leader of thick plates cutters, but with more operation cost and maintenance cost. This is the major difference of them, and you can dive into more details on our website to make a better option.

Also please do remember that never let the suppliers make the choice for you. They are accustomed to saying their machines are the best than others and can meet all your cutting need. In a word, to buy a suitable metal cutting machine, you should clearly know your condition (business plans, metal types to cut, budget, workplace environment, market potential, etc.), and then according to your condition analysis, choose a cutting machine that can be perfectly in line with your requirements.