Table of Contents

Application Case of Mini Laser Cutting Machine in Advertising Industry

Last month we signed a purchase contract with Julie from Quebec, Canada. He ordered a 1500 watt mini laser cutting machine from us for cutting metal nameplates, digital printing and signage. Here we will share the story between us.

We got in touch with Julie in October 2019. After understanding his cutting needs, we made a formal offer. But as every buyer did, our negotiations stopped in a long wait. Julie has received offers from so many suppliers, he cannot judge which supplier is better in a short time.

Six months later, I found Stephane in our company’s customer database. He is a colleague of Julie. Considering that Stephane’s company is a real and very powerful company in the local area, I think I can follow up our business again. I read all the emails about Stephane and did a background check on his company. It happened that our laser supplier lowered the price, so I updated the price to Stephane. What I didn’t expect was that Julie responded to me a week later.

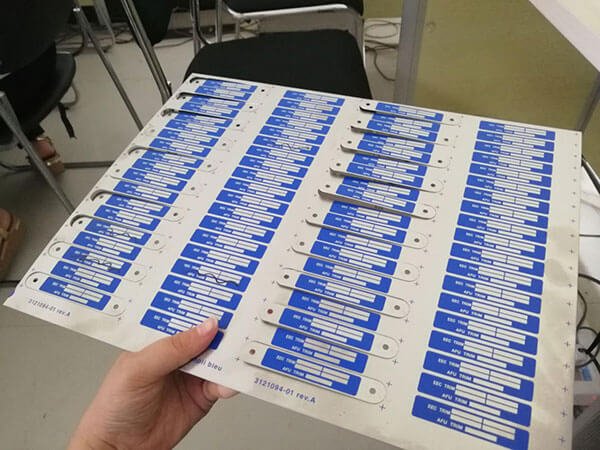

Julie is undoubtedly a very professional buyer. He hoped that we could give him some samples for testing and sent detailed drawings. After discussing with our engineers, we perfected the drawings and bought materials from the material factory for testing. The test result was undoubtedly very successful. We sent the video and pictures we took to Julie. Julie was very satisfied with our test. He asked whether it can be cut on screen printed metal sheets. He will send us some materials so that we can carry out cutting tests according to his drawings. We responded very quickly and sent our detailed address to Julie.

About a week later, we received his materials. Then I confirmed the cutting method and cutting requirements with Julie again, and made an appointment with the factory technician for time and machine. The next day I brought the materials to our workshop to start sample testing.

It was not very smooth at the beginning, and it was not that our machine could not cut his material. On the contrary, the cutting effect of our machine is very good. What embarrass us is the positioning of the materials. There are many patterns on the material, we must ensure that the cutting does not damage any lines, and there is no offset in all cutting positions. This requires that the position of laser cutting must be completely consistent with the graphic position of the software. And our function of manually positioning materials cannot meet his needs. After discussing with our technicians, we suggest to install an auxiliary positioning tooling to help us position the material.

Then we truthfully reflected the test results to Julie, and arranged to ship the sample materials to him. Julie was very satisfied with our test video and praised our honesty. Ask us to renew the offer and calculate the transportation cost of the machine.

Then we truthfully reflected the test results to Julie, and arranged to ship the sample materials to him. Julie was very satisfied with our test video and praised our honesty. Ask us to renew the offer and calculate the transportation cost of the machine.

About two weeks later, after their technicians tested the samples, Julie sent us a formal purchase request. Everything seems to be going very well, but we ignored the impact of the epidemic on us. Since the outbreak occurred in the laser production area, laser output in 2020 has dropped significantly. In order to meet the customer groups who placed orders during the epidemic, laser manufacturers have been working overtime every day to produce lasers after resuming production, which still cannot meet market demand. In desperation, laser manufacturers abandoned the production of low-power lasers. Therefore, we cannot complete Julie’s machine. I reluctantly explained the situation of the epidemic to Julie and provided a solution. I am very grateful that Julie and Stephane understand our situation very well and are willing to spend an extra $2,000 to upgrade to higher power lasers in stock.

I don’t know how to express my gratitude. Behind every order is the joint effort and mutual trust of buyers and sellers. I am so lucky to meet sincere customers like Julie and Stephane. I hope our machine can bring them more customers and money.