MORN LASER recently released 2019 new design of its metal laser cutting machines. Among which, Affordable Metal Laser Cutting Machine, one highly-integrated model is specially designed to cater to the rising needs of advertising industry. Aesthetically pleasing, it is affordable whilst quality guaranteed. This post will discuss the advantages of laser metal cutting in advertising industry, details of MORN LASER Affordable Metal Laser Cutting Machine for Advertising Industry and how it benefits the metal fabrication of the advertising industry.

Here is the outline:

- Advantages of Laser Metal Cutting in Advertising Industry

- MORN LASER Affordable Metal Laser Cutting Machine for Advertising Industry: Affordable without quality compromised

- How MORN LASER Affordable Metal Laser Cutting Machine Benefits Advertising Industry

Metal, as an important processing material, is not new in advertising industry. A variety of gorgeous metal signs, metal billboards, metal lightboxes, etc. have become part of the public. Metal products are durable and practical, bright and colorful, and offer a sense of grandeur, luxury, exquisiteness, and heaviness.

As the “protagonist” in the advertising industry, the metal signs can bring the simplest, most direct and effective publicity effect to the enterprise. Metal signs are not only used for outdoor publicity but also widely used in company logos, car logos, image walls, etc. Their durability can last 6-10 years outdoor, and more indoor. In addition, they can be creatively made into different shapes. More and more companies and institutions choose metal signs to establish their business image.

To take a lead in today’s highly competitive advertising market, a suitable highly efficient metal cutting machine is required for perfect processing, which not only retains the characteristics of the metal, but also ensures the precision of the processing.

Table of Contents

Advantages of Laser Metal Cutting in Advertising Industry

As a large and promising consumer industry, the processing of thin metal in the advertising industry has always been the focus. When people are happy that traditional mechanical cutting equipment can cut out various advertising words, they are inevitably bothering by its shortcomings such as low processing efficiency and precision, tool wear, material waste and other problems, which make the improvement of technology and equipment imminent.

The emergence of laser cutting equipment has undoubtedly injected new life into the advertising industry. It not only helps metal fabricators save operation costs but also increase production efficiency, precision and flexibility. Compared to conventional metal cutting methods, laser metal cutting has the following advantages:

- High cutting quality

Laser cutting presents certain advantages over plasma cutting as this process is more precise and uses less energy when cutting steel and aluminum sheets. In addition, a 7KW machine, are now approaching plasma machines in their ability to slice through thick metal sheets.

It can realize precise cutting of workpieces with small material volume and high precision. Furthermore, it creates narrow slits (the width of the slit is generally 0.1-0.2 mm), and smooth cutting edge, the roughness of the cutting surface is generally controlled within Ra6.5. Normally, laser cut metal products has no need for secondary rework.

- High cutting efficiency

Laser cutting has obvious advantages over saw cutting and waterjet cutting in terms of speed. As a flexible, non-contact, profiling tool, the laser can cut from any point in the material to cut in any direction which the sawing cutting is difficult to reach. The speed of waterjet cutting is extremely slow, and carbon steel cut by waterjet is easy to rust, water pollution is serious.

- Low operation cost:

There is no “tool” in contact with the material to be processed during laser cutting so there is no tool wear of the conventional cutter. Computer programming can be used to cut products of different shapes to maximize the utilization of materials so as to reduce the metal wastes. The metal to be cut directly and does not need to be fixed by a fixing device, thereby ensuring flexibility and maneuverability in the laser cutting process. Furthermore, the vibration is small and pollution-free during the laser cutting process, which effectively protects the heath of the operator.

MORN LASER Affordable Metal Laser Cutting Machine for Advertising Industry: Affordable without quality compromised

Although the laser cutting machine demonstrates many advantages over traditional methods, still many metal fabricators are hesitating in bring it in house. One of the main reasons that stopped them from going further is the high machine price.

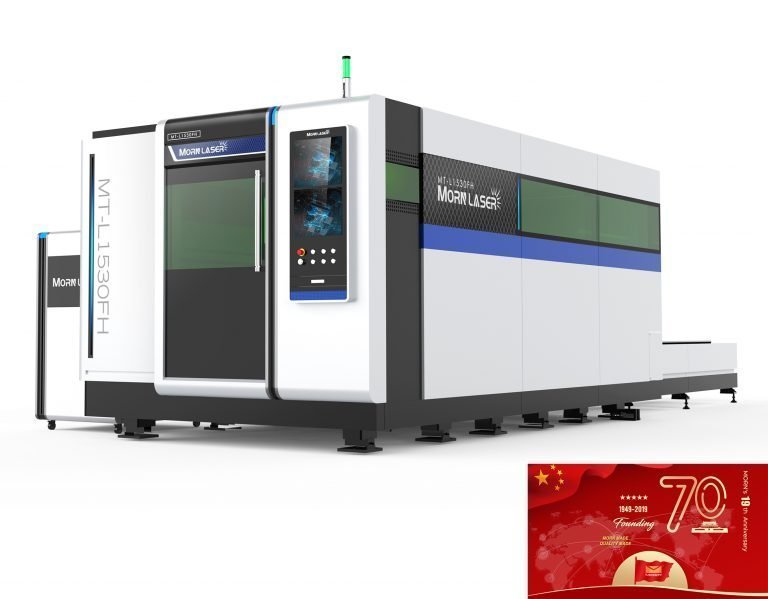

MORN LASER, after investigating the characteristics of the metal cutting in advertising industry and improving the machine production costs, has developed one Affordable Metal Laser Cutting Machine for Advertising Industry. This laser cutter is cost-effective and rightly hit the needs of the metal fabricators. It can meet the high-efficiency cutting and hollowing out of most metal materials, and is a good helper for metal processing in the advertising industry. Let’s have a look at the details.

- Structure and appearance

The new design is compact and eye-pleasing. The whole machine is highly integrated. The control screen, control cabinet are integrated into the machine body which further cut floor area. This will benefit shops with limited processing space.

- Quality assurance by configurations

Domestic first-class laser source-Raycus

With the continuous maturity of domestic laser technology and the sharp drop in price,

the mainstream laser source of low-power metal laser cutting machine (below 1000 watts) is domestic first-line brands such as Raycus. Since 1KW laser can cut the thickness of up to 10mm CS, 5mm SS, 3mm aluminum and copper, which fully satisfies most metal sheet processing requirements in advertising industry.

With 100,000 hours of lifetime and excellent beam quality, Raycus laser source performs very stably in the whole metal processing.

Switzerland Raytools Cutting Head

- Configurable

How MORN LASER Affordable Metal Laser Cutting Machine Benefits Advertising Industry

MORN LASER affordable laser cutting machine can be widely used for multiple processing of advertising industry.

- Signboard sheet metal cutting

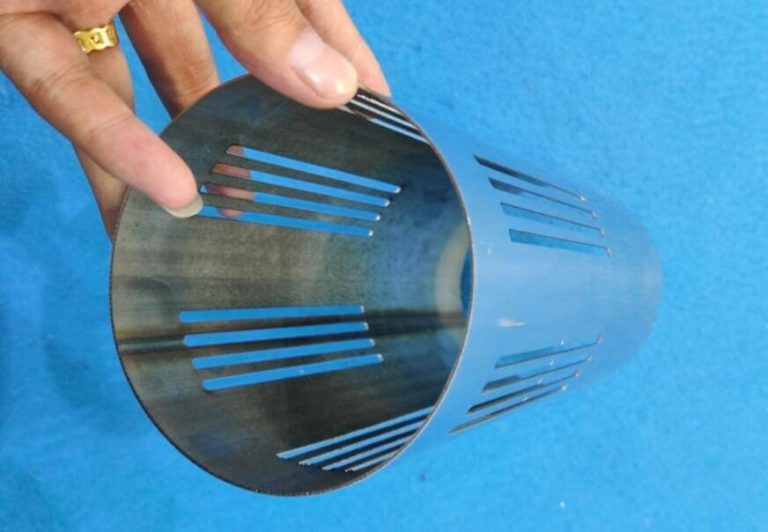

Going out, street signs and signage are the best tools to guide the road. But there is an advertising sign that looks like a street sign, but it is actually a billboard. Advertising signboards usually require a thin metal material, and the laser can be used to quickly and precisely cut thin metal sheets.

- Advertising light box metal sheet cutting

The advertising light box combines the advantages of neon light, which can effectively improve people’s visual impact and achieve a good publicity effect. The fiber laser cutting machine is suitable for the processing of various thin metal materials such as iron, stainless steel, titanium gold, and copper. After laser cutting, the metal plate of the advertising lightbox can be directly painted and welded without secondary processing.

- Advertising metal display stand cutting

The advertising metal display stand combined with the creative company LOGO can increase product promotion. The use of laser to cut a variety of metal display frame thin metal plate, with the late electrostatic spraying, baking process, to achieve exquisite, durable and durable product effects.

A design-filled signage allows you to not only love the space in front of you, but also the “brand” that fills the planning sense. Just abandon the old antiques, signboards without planning beauty, use the signboard of the laser hollowing skills, low and intrinsic.