Table of Contents

8 Important Components of Fiber Laser Cutting Machine

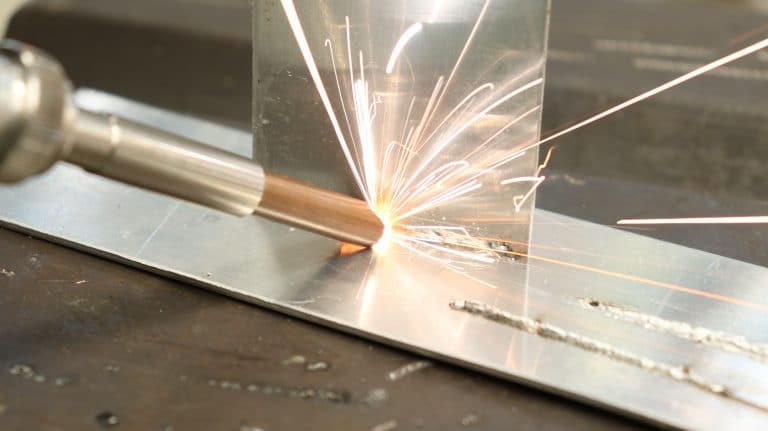

Fiber laser cutting machine outputs high-energy-density laser beam which is concentrated on the surface of the workpiece, therefore the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by the CNC mechanical system to achieve automatic cutting by irradiating position, fast speed and high precision.

Laser cutting processing has replaced the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to the cutting pattern, automatic typesetting, saving material, smooth cutting, and low processing cost.

Its excellent performance, extremely high speed, high conversion rate and many other advantages has made it widely used in machining and machinery manufacturing industries, among which the most typical are sheet metal cutting, kitchenware, electric cabinet, automotive car field, and so on.

Core Components of Fiber Laser Cutting Machine

1. Fiber laser source

It is the most core component of fiber laser cutting machine, and it is also the “power source” for fiber laser cutting machine to realize cutting operation. Compared with other types of lasers, fiber lasers have the advantages of higher efficiency, longer service life, less maintenance, and lower cost. The widely used best laser source brands are Raycus and IPG.

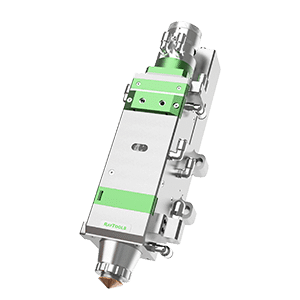

2. Laser Cutting Head

The cutting head of the laser cutting machine is a laser output device, which consists of nozzle, focus lens and focus tracking system. The cutting head of the laser cutting machine will travel according to the set cutting track, but the height of the laser cutting head needs to be adjusted and controlled under different materials, different thicknesses, and different cutting parameters. Usually manufacturer will equip with Raytools laser head at low-mid power machines. For high power from 8KW to 12KW normaly equip Germany Precitec laser head.

3. Servo Motors

Servo motor refers to an engine that controls the operation of mechanical components in a servo system. It is an auxiliary motor indirect speed change device. The servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. The high-quality servo motor can effectively ensure the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutting machine. For example, Japan Yaskawa is reliable high quality servo motor brand.

4. Water Chiller

The chiller is the cooling device of the laser cutting machine, which can quickly and efficiently cool the laser source, laser head and other devices. The current chillers all contain input and output control device switches, as well as advanced functions of cooling water flow, high and low temperature alarms, and their performance is more stable. S&A is one of the hotsell industrial water chiller.

5. Air Cutting System

The air cutting system of fiber laser cutting machine mainly includes air compressor, filter device and air dryer. Among them, there are two kinds of air sources: bottled air and compressed air. Air cutting is ecocomical than other gas cutting, the reason to use air cutting is to save gas consumption cost comparing to Nitrogen.

6. Host

The bed, beam, table, and Z-axis system of the laser cutting machine are collectively referred to as the host. When the laser cutting machine performs cutting, first put the workpiece on the bed, and then use the servo motor to drive the beam to control the movement of the Z axis. The user can adjust the parameters according to their own needs.

7. Control system

It mainly controls the machine tool, realizes the movement of X, Y, Z axis, and also controls the output power of the laser.

8. Stabilizer

Connected between the laser, CNC machine tool and the power supply system. Mainly play a role in preventing external grid interference.

Therefore, when we choose laser equipment, we don’t only consider the characteristics of our product materials, but also consider the performance of the laser equipment, so that we can find the laser equipment suitable for our industry products. MORN Laser focus on providing customer high quality reliable equipment, for more details please browse here: http://www.morntech.com/fiber-cutting/