For most amateurs, laser engraving, laser marking and laser etching may work in the same way and produce similar products. And indeed these three technologies can be used interchangeably in some circumstances, but they do have their own characteristics and usages respectively. This article will give an explanation on the main differences among them.

1. Laser Engraving

Based on computer numerical control (CNC) technology, laser engraving works in a way that the laser beam removes the surface of the materials selectively as per the patterns output from the computer. And then an image or pattern will be appeared on the surface of materials. It differs from laser marking and etching in 5 ways:

- According to the material surface and how much you remove, laser engraving can be divided into etching, laser ablation and deep laser engraving.

- This can engrave a wide range of materials, such as plastic, leather, metal, glass, etc.

- Best for personalization and customization.

- This is the fastest laser marking way.

- Do not touch the surface of materials during engraving process.

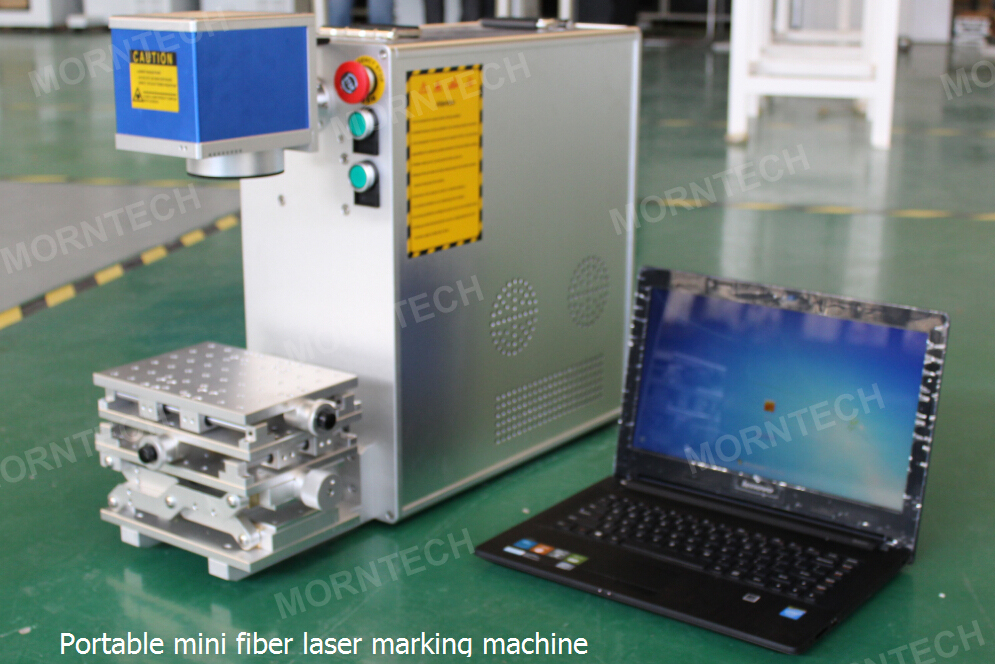

2. Laser Marking

As one of the most widely used application fields of laser technology, laser marking is mainly used in advertisement industries, construction industries and signage production industries. It’s a process where laser beam works on the surface of a material, changing its appearance subtly and permanently. From millimeter level to micron size, laser marking can process various characters, symbols and patterns, which plays a meaningful role in anti-fake systems. It differs from laser engraving and laser etching in the following 4 ways:

- It consists of annealing, carbon migration, foaming and coloration.

- It’s less common than laser engraving or etching.

- It’s usually used in medical device industry.

- It’s ideal for marking logos, bar codes, UID codes and other identification objects.

3. Laser Etching

As a subset of laser engraving, laser etching is a process that the heat produced by laser beam melts the surface of materials. This heat has a pretty high temperature which causes the materials to raise a mark, with the depth being no more than 0.001”. It differs from laser engraving and marking in the following ways:

- It changes the reflectivity of the materials and enhances contrasts between marked areas and unmarked areas.

- Less productive than laser engraving and marking and not suitable for mass production.

Even though these three types of laser technology all have their advantages and disadvantages in processing materials, they are indispensable and contributory to modern industries and society.

For more details for laser engraving, laser marking and laser etching, please feel free to contact us and we will provide you professional laser advice via our experts and the industry partners.