The automobile industry is a comprehensive industry developed on the basis of many related industries and related technologies. Now the laser welding machine production line has appeared on a large scale in the automobile manufacturing industry and has become one of the outstanding achievements of the automobile manufacturing industry. Many automobile manufacturers use laser welding and laser cutting processes. High-strength steel plate laser welding assembly parts are increasingly used in automobile body manufacturing due to their excellent performance. Because of the large volume and high degree of automation in the automotive industry, laser welding equipment will develop in the direction of high power and multiple channels.

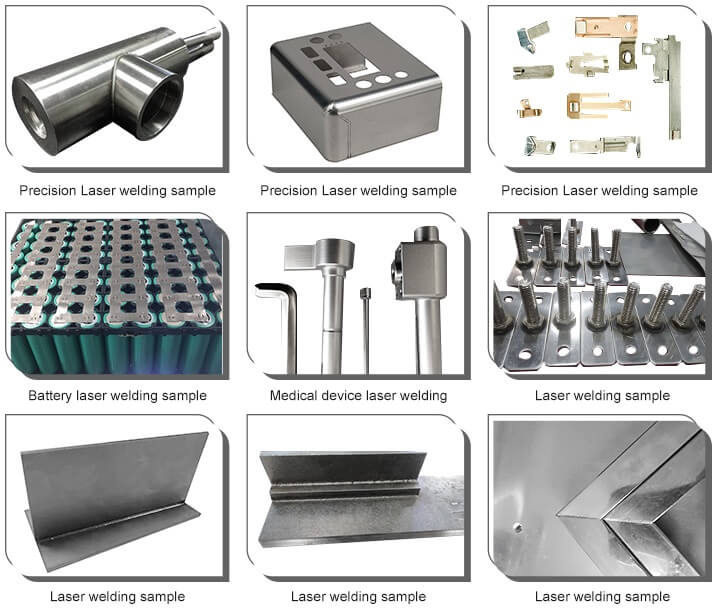

Laser welding machine is a thermal processing technology that uses laser beam as heat source. Compared with electron beam plasma beam and general mechanical processing, laser welding machine has small laser focal spot, high power density, and can weld some alloy materials with high melting point and high strength. And many other advantages. For example, in the automotive industry.

- Car body welding:online laser welding in the automotive industry is widely used in the assembly and connection of body stamping parts. The main applications include laser welding of the roof cover, luggage lid laser welding and frame laser welding; another important laser welding application of the body is the laser welding of body structure parts (including doors, body side frames and pillars, etc.) . The reason for using laser welding is to increase the strength of the car body and to solve the difficulty of conventional resistance spot welding in some parts.

- Laser tailor-welded plates of unequal thickness:the use of laser tailor-welded plates of unequal thickness in car body manufacturing can reduce body weight, reduce the number of parts, improve safety and reliability, and reduce production costs.

- Welding of gears and transmission parts.In addition, various parts of the gearbox can be welded on this equipment, especially the differential case and drive shaft in the car gearbox, which are often joined and welded after the production of individual parts. Become.

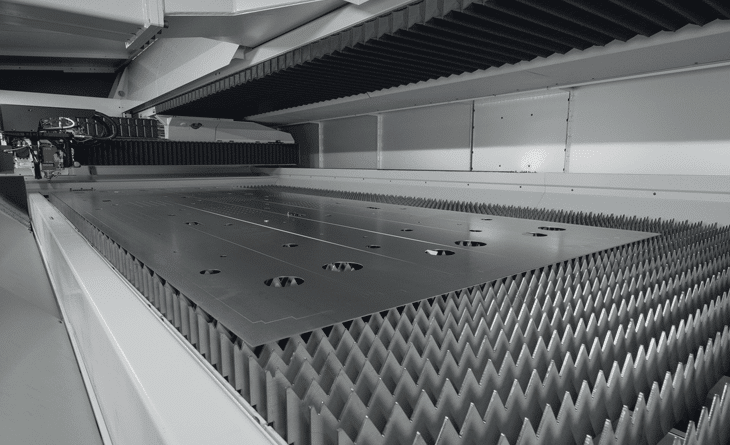

In order to adapt to the welding of various parts, there is a spacious maintenance door inside the equipment, which is very convenient and time-saving for replacement or maintenance. A new conveying method is adopted, which greatly improves the flexibility of the workpiece conveying channel, and greatly reduces the replacement time in small batch production.

The auto parts laser welding machine adopts a dual-station work platform, intelligent operation of robots, and is equipped with a wobble welding head. It collimates parallel light through a collimator lens and focuses on the workpiece to perform welding. With a simple universal instrument, it can perform flexible transmission and non-contact welding on the welding precision parts that are inaccessible to large molds, which has greater flexibility in operability.

Table of Contents

Product features of laser welding machine for auto parts:

- Using Yaskawa or other manipulators, equipped with fiber lasers, the production efficiency is greatly improved.

- The flexible work platform can design fixture combinations according to customer needs to meet the needs of automated welding production.

- Continuous wave output, good welding compactness and high strength.

- The laser heat is concentrated, the welding speed is fast, and the thermal deformation is small.

- Non-contact, atmospheric welding process. Because the energy comes from the laser, the workpiece has no physical contact, so no force is applied to the workpiece, and the magnetic field has no effect on laser welding.

- Due to the low average heat input and high processing accuracy, reprocessing costs can be reduced. In addition, laser welding operation costs are lower, which can reduce workpiece costs.

- It is easy to realize automation, and can effectively control the beam intensity and fine positioning.

Morn laser welding machine equipment exerts superior performance in the production and application of automobile parts, which is of great significance to the improvement of automobile manufacturing level.

Morn Laser is a high-tech enterprise integrating R&D, production and sales of professional laser complete equipment. Committed to providing global users with a full range of solutions such as laser intelligent cutting equipment, welding equipment, and automated production lines. Its fiber laser cutting machine, three-chuck laser pipe cutting machine, handheld laser welding machine, automatic laser welding machine, and robotic laser welding machine have been used by many customers in the automotive industry. At the same time, we can also develop new products according to market demand, continue to innovate, and meet the diversified requirements of customers.