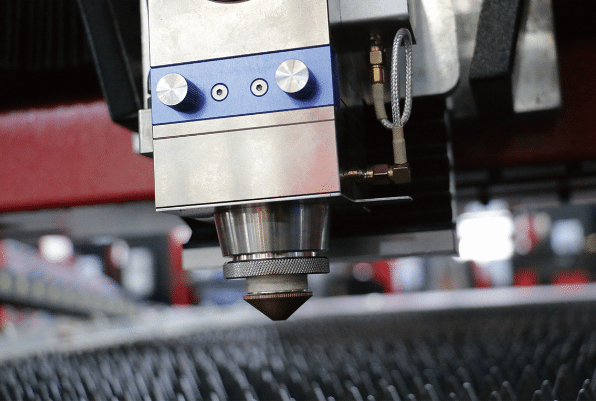

Function setting of laser pulse spot welding:

The heat input of this function welding repair is extremely small, the welding repair is accurate, and the precise and small parts can be easily repaired.

Table of Contents

Welding characteristics:

- 1. Small heat-affected zone, no need for pre-heat treatment

- 2. There is no deformation, no pores, and trachoma.

- 3. Accurate and precise can weld small and precise geometric areas, the smallest wire can be 0.1-0.2mm.

- 4. It is convenient and flexible to use, and can be directly repaired on-site, which can avoid expensive separation of the workpiece or repair part.

- 5. It can be used to repair cracks, chippings, edges and corners, sand holes, and mold wear.

- 6. Use different hardness materials to obtain different hardness after welding. Welding can also be performed on the toughness of the cold die and the cutting edge of the tool, eliminating the cumbersome process of preheating and heat preservation of ordinary argon welding.

Application in the mold industry

- Injection mold

- Stamping mold

- 3 Die casting mold

- 4 Rubber mold

- 5 Copper alloy mold

Application in the foundry industry

This welder also has a good surface in casting defects. The pores, slag holes, and shrinkage holes in the casting process can be repaired quickly and accurately.

It has excellent repair effects on defects such as ductile iron, gray iron, stainless steel, etc., fast welding repair speed, no color difference, or small color difference after welding, suitable for the needs of factory-scale production. It is recognized that the machine tool track surface which is more difficult to repair has also been solved ideally.

Application in various workpiece parts repair industry

This machine can perfectly repair shafts, teeth, and other workpieces.

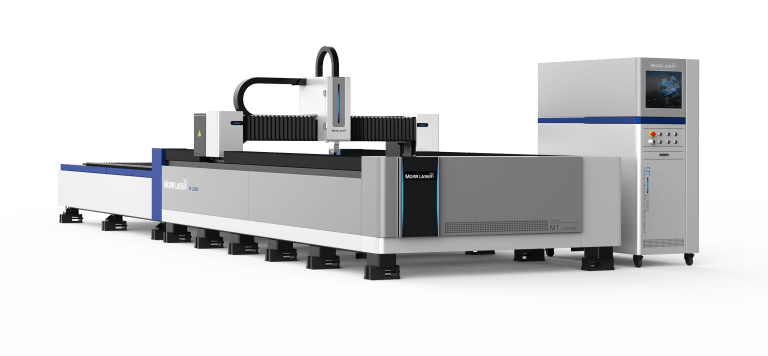

Application: Fully automatic welding for mobile phone shells with high precision, beautiful welding pattern and high efficiency; hermetic welding of metal parts of medical equipment; precision welding of mobile phones, MP3, metal shells, and internal structural parts are widely used in electronic devices and household appliances, Jewelry, glasses, hardware, auto parts, communications, and other industries. Special laser welding machine for mobile phone hardware shell, super large mold laser welding machine, high-power mold welding machine, dual-lamp high-power battery welding machine, dual-lamp high-power automatic welding machine.

Compared with other types of welding machines:

- Comparison with ordinary argon arc welding machine

Due to the large input energy of the ordinary argon arc welding machine, the welding repair has a large impact on the workpiece, so the workpiece is prone to deformation, discoloration, undercut, and other phenomena after welding. Especially for stainless steel products with thin materials, this welding machine successfully overcomes this difficulty and makes precise welding and welding repair a reality.

- Comparison of cold welding machines

Cold welding machines (such as resistance welding, placement machines, etc.) in the current market generally have disadvantages such as slow repairing speed, low bonding after welding, and less welding materials, which cannot meet the individual needs of manufacturers. The welding machine has the advantages of fast welding repair speed, high degree of bonding after welding, and full welding materials. Different materials are selected for different welding materials.

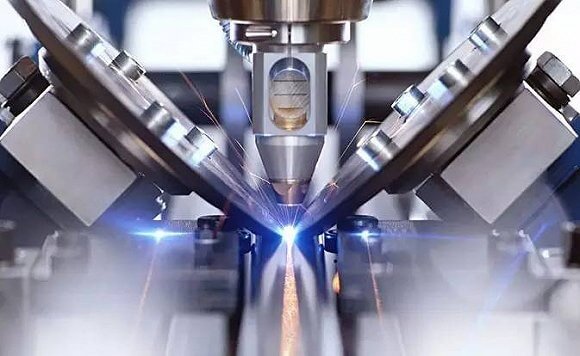

Compared with traditional mechanical processing, laser processing has the following characteristics:

- Fast processing speed;

- Small heat distortion and heat-affected zone (suitable for processing high melting point, high hardness, special materials)

- The parts can be locally heat-treated;

- It can process parts with complex shapes and small parts, and can also be processed in a vacuum;

- No noise during processing and no pollution to the environment;

- Combined with computer technology, it is easy to realize automation;

- Due to advanced processing methods, existing product structures and materials can be improved

- It can improve the quality of the workpiece.