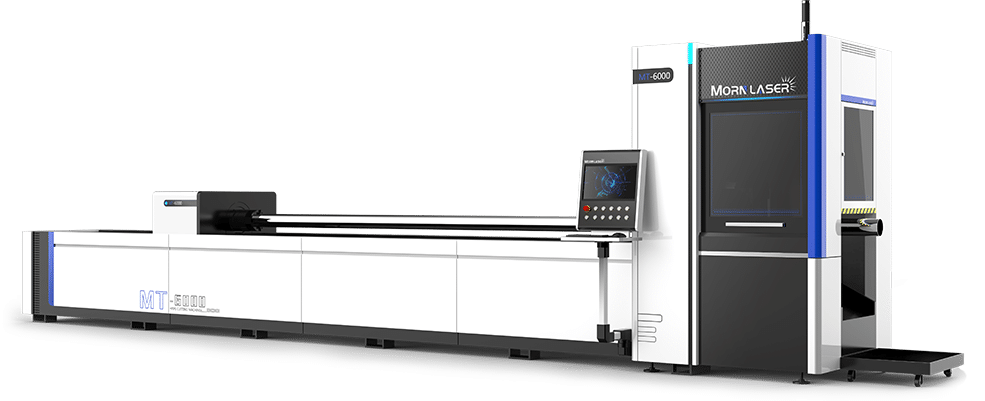

What are the four points of choosing a tube fibre laser cutting machine? As a manufacturer of laser tube cutting, we all hope to buy the best, most stable and most affordable laser tube cutting machine. Then this requires the laser tube cutting manufacturer to be familiar with the knowledge of the laser tube cutting machine, so the following is the laser tube cutting manufacturer, some experience and knowledge summed up when purchasing the laser tube cutting machine, I will share with you here.

Table of Contents

Four point selection tube fibre laser cutting machine

- Laser lens:

Generally, the better the laser lens is, the more laser light is reflected, and the less laser loss is. This will help increase the photoelectric conversion rate of the laser tube cutting machine. There are two types of lenses: imported lenses and domestic lenses. Domestic lenses are divided into two types: imported materials and domestic materials. There is a big price gap, and a big gap in use effect and service life.

- Operating software

The operating software used by the laser tube cutting machine is the brain of the entire equipment, which controls the laser generator and the vibrating lens. The speed of the laser generator’s light output is fast and slow. The high and low light power is controlled by software. The vibration speed and angle of the vibrating lens , The direction of light is controlled by the operating software, so the operating software plays an important role in the equipment, and good accessories must also be coordinated by good software to play the greatest role.

- Laser vibration lens

The speed and accuracy of the laser tube cutting machine depend on the speed and accuracy of the vibrating lens. The temperature of the vibrating lens will be generated in the working state. As the working time is longer, the temperature will be higher. If the vibrating lens cannot withstand long hours of work, it will cause precision deviation , The speed will also decrease. The vibrating lens is currently the accessory with the highest failure rate of the laser marking machine, so choosing a good vibrating lens plays a key role in the stability of the equipment.

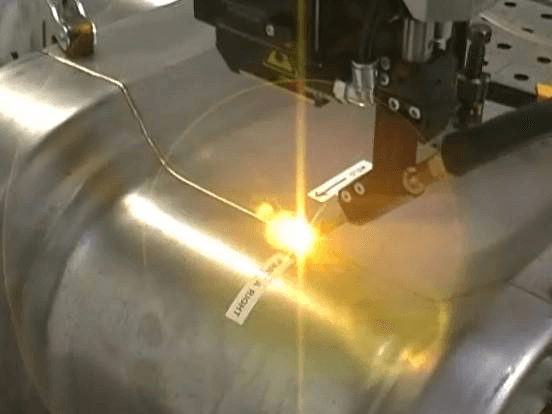

- Laser generator

Because the laser generator is the core part of the entire laser marking machine, its quality determines the quality of the laser tube cutting machine. Generally speaking, imported lasers are better, with good beam quality and high electro-optical conversion rate. Domestic lasers are slightly inferior, but domestic lasers can also meet the needs of any industry. With the rapid development of the laser industry, laser tube cutting machines In terms of application, domestic technology is becoming more and more mature. Now the technology level is close to the international level, and the service life is more than 3-4 years. You can also buy with confidence. Although the imported laser generator will produce more refined effects, it is more expensive and troublesome to maintain. If there is a fault, it needs to be sent abroad. The customs declaration procedures are more cumbersome and the maintenance cycle is long; relatively speaking, domestic laser generators It can basically meet everyone’s requirements and has low cost. Maintenance is quick and easy.

From the above 4 points, the laser tube cutting processing can be summarized into four points: choose a better domestic laser lens, choose a stable operating software with a high usage rate, choose a good laser vibrating lens, preferably an imported laser. Familiar with the important accessories of these laser pipe cutting machines, generally you can choose a better laser pipe cutting machine.