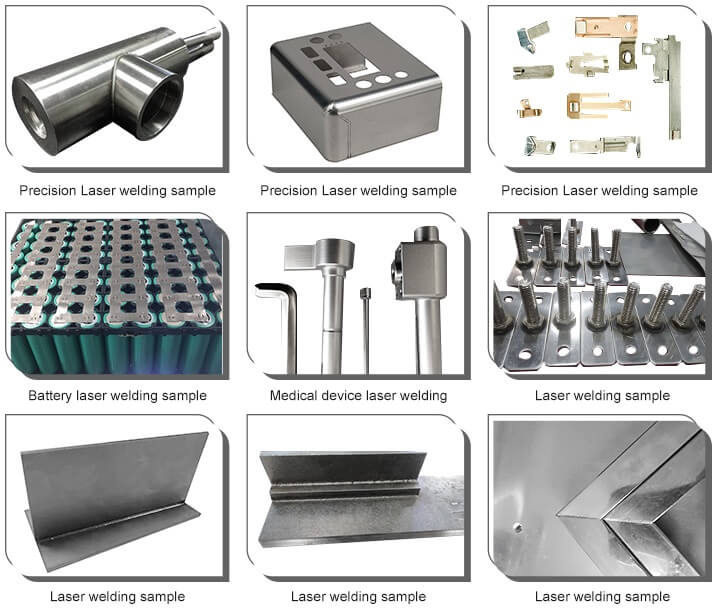

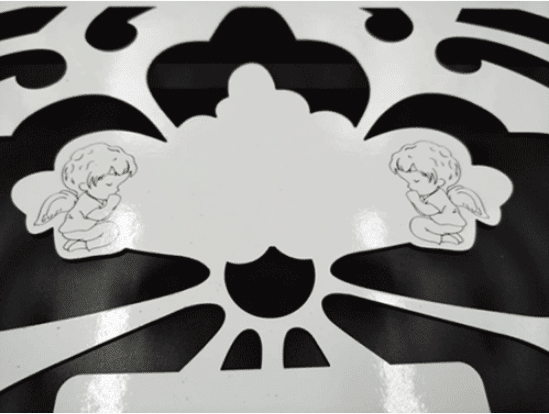

Laser cutting is achieved by applying high power density energy generated by laser focusing. Under the control of the computer, the laser is discharged through pulses, thereby outputting a controlled repetitive high-frequency pulsed laser to form a beam with a certain frequency and a certain pulse width. The pulsed laser beam is guided and reflected by the optical path and is focused by the focusing lens group. On the surface of the processed object, a small, high-energy density light spot is formed. The focal spot is located near the surface to be processed, and the processed material is melted or vaporized at an instant high temperature. Each high-energy laser pulse instantly sputters a small hole on the surface of the object. Under computer control, the laser processing head and the processed material perform continuous relative movement according to the pre-drawn graphics, so that the object will be processed into The shape you want.

When the laser cutting machine is working, it is very dangerous if it fails. Novices must be trained by professionals to operate independently. The experts of the laser cutting machine have summarized 13 details of the safe work of the laser cutting machine based on experience, and I hope to help ,as follows:

- Comply with the general safety operation regulations of cutting machine. Start the laser strictly in accordance with the laser start procedure.

- The operator must be trained, familiar with the structure and performance of the equipment, and master the relevant knowledge of the operating system.

- Wear labor protection equipment according to regulations, and must wear protective glasses that meet the regulations near the laser beam.

- Don’t process a material before it is clear whether it can be irradiated or heated by laser to avoid the potential danger of smoke and steam.

- When the equipment is started, the operator shall not leave the post or be taken care of without authorization. If it is necessary to leave, the operator should stop the machine or cut off the power switch.

- The fire extinguisher should be placed within easy reach, the laser or shutter should be turned off when not processing, and no paper, cloth or other flammable materials should be placed near the unprotected laser beam.

- When an abnormality is found during the processing, the machine should be shut down immediately, and the fault should be eliminated or reported to the supervisor in time.

- Keep the laser, the bed and the surrounding area clean, orderly, and free of oil pollution,workpieces, plates, and waste materials are stacked as required.

- When using gas cylinders, avoid crushing the welding wires to avoid leakage accidents. The use and transportation of gas cylinders shall comply with gas cylinder supervision regulations. It is forbidden to explode gas cylinders in the sun or close to heat sources. When opening the bottle valve, the operator must stand on the side of the bottle mouth.

- Observe high-voltage safety regulations during maintenance. Every 40 hours of operation or weekly maintenance, every 1,000 hours of operation or every six months of maintenance shall be carried out in accordance with regulations and procedures.

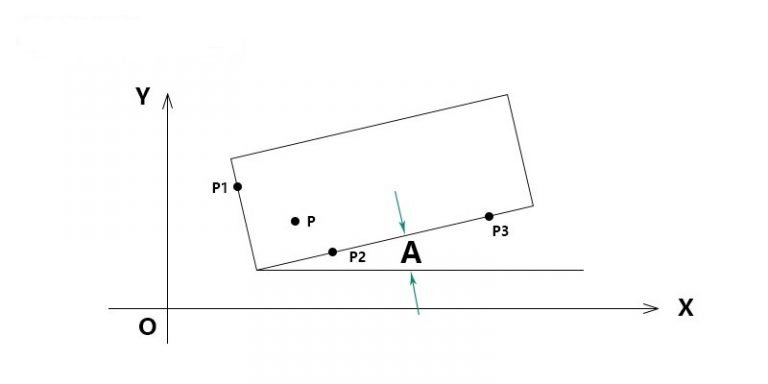

- After starting the machine, the machine should be manually started in the x and Y directions at low speed, and check to confirm whether there is any abnormality.

- After inputting the new part program, try to run it first and check its operation.

- When working, pay attention to the operation of the machine tool to avoid accidents caused by the cutting machine going out of the effective stroke range or collision between two machines.