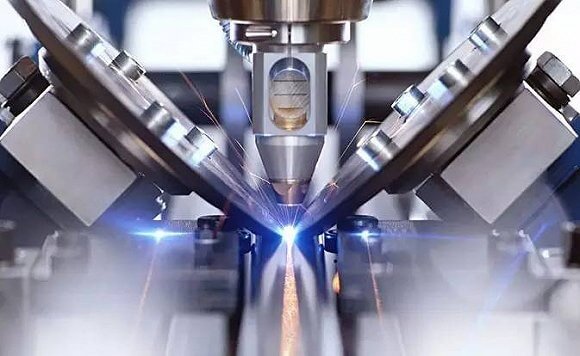

The automobile industry is one of the main application fields of laser welding equipment in China at present. Laser welding has become one of the important means in industrial manufacturing because of its advantages of high energy density, small deformation, narrow heat-affected zone, high welding speed, easy automatic control, and no subsequent processing. The automobile manufacturing industry is one of the largest industries using laser welding technology in current industrial production. The flexibility of the laser welding machine satisfies the processing of various automobile materials, reduces automobile production costs, improves production efficiency, and brings huge economic benefits to the automobile manufacturing industry. Laser welding technology is mainly used for automatic laser welding of automobile body-in-white roof, laser welding of multiple gears, laser welding of airbag igniter, laser welding of the sensor, laser welding of battery valve, etc.

Table of Contents

Application of laser welding in the automobile field

In the automobile industry, laser welding is usually applied to the key stations of car body welding and the parts with special requirements for technology. For example, it can solve the problems of welding strength, efficiency, appearance, and sealing when used for welding the roof and sidewall outer panel; It can solve the problem of right-angle lap joint when used in rear cover welding; Laser tailor welding for door assembly can effectively improve welding quality and efficiency. Different laser welding methods are often used in the welding of different body parts. Here are some laser welding methods commonly used in the automobile industry.

(1) laser brazing

Laser brazing is mostly used for the connection of roof and sidewall, trunk lid, etc. Volkswagen, Audi, Peugeot, Ford, Fiat, and Cadillac are all using this welding method.

(2) Laser self-fusion welding

Laser self-fusion welding belongs to deep fusion welding, which is mainly used for roof and sidewalls, doors, etc. At present, many brands of cars from Volkswagen, Ford, GM, and Volvo are processed by laser self-fusion welding

(3) Laser remote welding

Laser remote welding uses robot+galvanometer and remote beam positioning+welding, which has the advantages of greatly shortening positioning time and higher efficiency compared with traditional laser processing, and has been gradually popularized in Europe and America.

Characteristics of laser welding automobile body

- Non-contact processing

The most important advantage of laser welding in automobile manufacturing is the advanced non-contact machining method. Traditional processing methods such as screw fastening and adhesive connection can not meet the requirements of precision and firmness in modern automobile manufacturing, and the application of new materials also makes the traditional processing methods slightly inferior. Laser welding is non-contact, and precision welding can be realized without touching the product in the processing process, which makes great progress in the connection firmness, seamless, precision, and cleanness.

- Laser welding improves the lightweight of automobiles

Using laser welding can replace castings with more stamping parts in automobile manufacturing, and replace scattered spot welds with continuous laser welds, which can reduce the lap width and some reinforcing parts, reduce the volume of the automobile body structure itself, thus reducing the weight of the automobile body and meeting the requirements of automobile energy saving and emission reduction.

- Improve the assembly accuracy and stiffness of the car body

There are hundreds and thousands of parts in the body and chassis of a car. How to connect them together has a direct impact on the rigidity of the whole car body. Laser welding can connect almost all metal materials with different thicknesses, grades, types, and grades. The welding accuracy and assembly accuracy of the car body is greatly improved, and the rigidity of the car body is increased by more than 30%, thus improving the safety of the car body.

- Laser hybrid welding improves process stability

Compared with pure laser welding technology, using laser hybrid welding technology can greatly improve the connection ability of gaps in sheet metal parts, so that enterprises can make full use of the technological stability of arc welding in laser high-speed welding.

In addition, laser welding can also reduce the stamping and assembly costs, shorten the production cycle, reduce the number of parts, and improve the integration degree of the automobile body. Laser welding parts have almost no deformation at the welding parts, the welding speed is fast, and no post-welding heat treatment is needed. At present, laser welding parts have been widely used, which are common in transmission gears, valve lifters, door hinges, and so on.