Fiber laser cutting machines have been gradually popularized in metal processing industries. We believe many laser machine investors have interest in the question that which industries are the mainstream application field of fiber laser cutting machine, so that to develop their laser business better. Below we concluded 9 main applications of fiber laser metal cutting for your reference.

1. Decoration industry

Thanks to the high speed and flexible cutting of the fiber laser cutting machine

, many complex graphics can be quickly processed by efficient fiber laser cutting system and the cutting results have won the favor of decoration companies. When customers ordered a special design, the relevant materials can be directly cut out after the CAD drawing is made, hence there is no problem in customization.

2. Automobile industry

Many metal parts of the automobile, such as car doors, automobile exhaust pipes, brakes, etc. can be processed precisely by fiber laser metal cutting machine. Compared with traditional metal cutting methods like plasma cutting, fiber laser cutting ensures wonderful precision and work efficiency, which highly improves the productivity and safety of automobile parts.

3. Advertising industry

Due to the large number of customization products in the advertising industry, the traditional processing method is obviously inefficient, and the fiber laser metal cutter is quite suitable for the industry. No matter what kind of designs, the machine can produce high quality laser cut metal products for advertisement use.

4. Kitchenware industry

Nowadays people have higher demand on the design and application of kitchenware, so kitchen-related products have a promising market around the world. Fiber laser cutting machine is very suitable for cutting thin stainless steel with fast speed, high precision, good effect, and smooth cutting surface, and can realize customized and personalized products development.

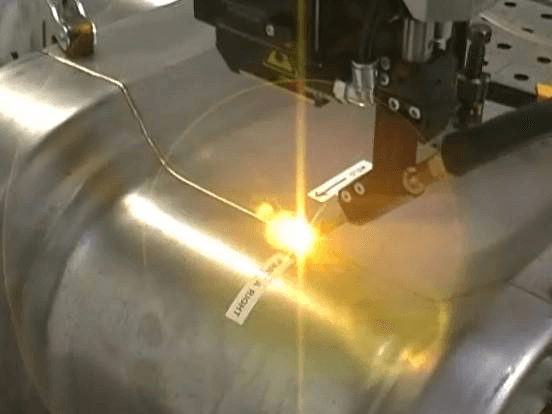

5. Lighting industry

At present, mainstream outdoor lamps are made of large metal pipes that are manufactured with different cutting types. Traditional cutting method not only has low efficiency, but also can not achieve personalized customization service. Fiber laser metal plates and pipes cutter rightly serve as a perfect laser solution that solves this problem.

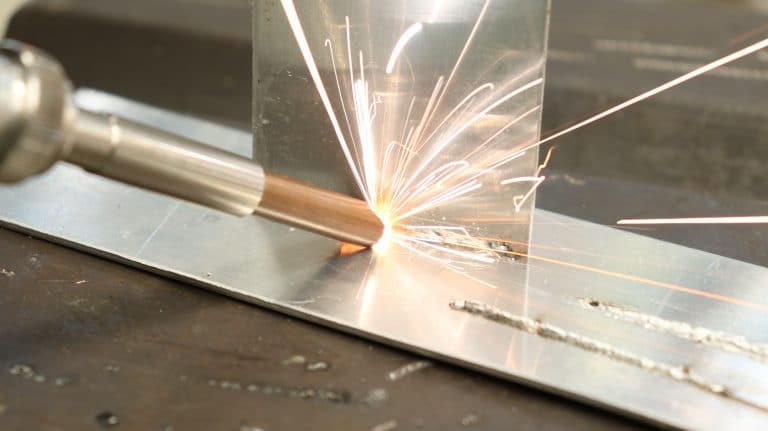

6. Sheet metal processing

Fiber laser cutting machine is born to process metal sheets and pipes in modern metal processing industries where precision and productivity are increasingly required. MORN fiber laser cutters have shown reliable and highly efficient cutting performance according to our customers’ feedback, you could also check this post to learn more about the features and advantages of our fiber lasers.

7. Fitness equipment

Public fitness equipment and home fitness equipment have developed rapidly in recent years, and the future demand is particularly large. Fitness equipment manufacturing industries have been booming with the fiber laser metal cutting technology being introduced. More information about fitness equipment laser cutting, please read this linked article to get more insights.

8. Home appliance industry

With the development of modern technology, the traditional processing technology of the home appliance manufacture industry continues to transform and upgrade. Metal laser cutting machine is one of the most powerful processing methods in current metal processing industry. In the home appliance manufacturing process, whether it is to improve the processing quality or optimize the appearance of the product, there is much to do for fiber laser cutters.

Fiber laser cutting machine has the incomparable flexibility and processing precision of the traditional processing method. Because it uses “contactless processing” method that does not need mold making and extra cost. Therefore, fiber laser cutting technology can effectively improve product quality, reduce production costs, reduce labor intensity, improve traditional sheet metal processing technology, and bring more benefits to manufacturers.