Table of Contents

Preparations Requirments for Fiber Laser Cutting Machine Installation

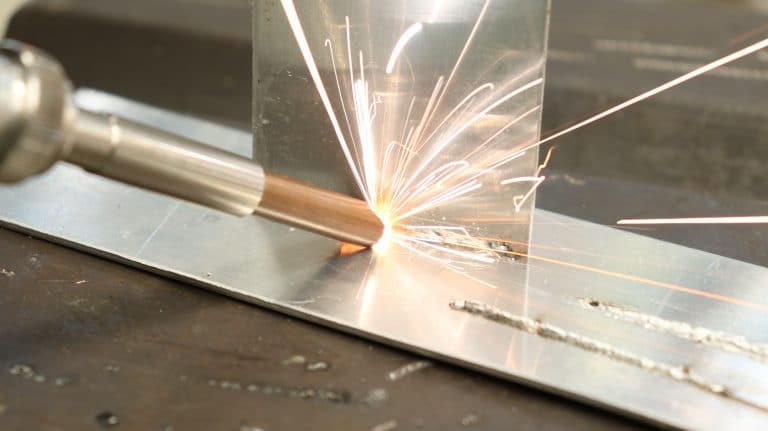

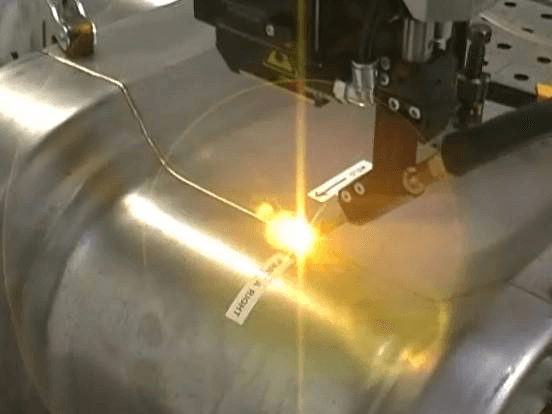

Fiber laser cutting machine, as a high-tech technology, it’s widely used among customers. For most customers who are first time to use fiber laser cutting systems, they all require our technican fly to their country for fiber cutting machine installation, testing and training. About machine installation, which things you need to prepare in advance? Here we list out as follows:

Forklifts:

Forklifts, with a slightly larger load capacity than the total weight of the fibre laser cutter, should be prepared in advance. For example, the fiber cutter total weight is 4 tons, customers should prepare 5-ton forklifts. Furthermore, pay attention to the overall weight of the fiber laser cutting equipment when packaging, in order to facilitate unloading of the fiber laser cutting machine.

Pls kindly note: we will use nails to fix the fiber laser cutting machine bottom bracket with container together, when you unload the fiber laser cutter, you need to remove the nails firstly, otherwise it will be very difficult for you to unload the machine.

Laser level:

It’s for level testing and adjustment of the fiber laser cutting machine

Adjustable wrenches:

It’s for loosening or tightening nuts and bolts or level the fiber laser cutting machine

Allen wrench and socket wrench:

It’s for the installation of the machine sheet metal. As the sheet metal hole of the fiber laser cutting machine system is very deep, so two sets of long hexagonal wrenches should be prepared.

Needle Nose Pliers:

It’s for installation of special parts

Multimeter:

It’s for testing of the circuit;

Distilled water:

Sufficient distilled water should be prepared for the water chiller;

Main power supply:

Switches for the main power supply should be selected and installed according to the total power of the machine in advance.

Chiller power supply:

Switches for the chiller power supply should be selected and installed according to the total power of the fiber laser cutting machine in advance.

Voltage stabilizer:

It’s used to stabilize the fiber laser cutting machine power voltage, slightly higher than the total power of the fiber laser cutter machine, to avoid the fiber laser cutting machine system is damaged by the unstable voltage.

Barometer, oxygen and nitrogen pressure gauges:

Pls prepare the gas according to the customer’s needs, as well as the corresponding barometer; please note that the pressure at the customers’ workplace may not match with China.

Slotted screwdriver and Phillips screwdriver:

It’s for the installation of sheet metal parts or lines

Electrodrill and taps:

It’s for inappropriate hole position, or other uses

Lubricant:

Lubricant for the rail of the fiber laser cutting system should be prepared in advance

Degreasing cotton:

At least 2 packs, for cleaning of the lens

500ml alcohol, purity above 99.5%:

It’s for cleaning the accessories of the optical systems

Paper tape, scotch tape:

It’s used to adjust the light path center or other uses

Plates and tubes materials:

Different customers have different requirment, you can prepare according to yourself needs.

The power supply position of water chiller, 2 exhaust fans power supply positions:

It’s used for install the corresponding switchs

Five-core wire for machine power:

The wire at least 10 square meters

Prepare air compressor

Prepare the dryer

The meals, hotel, training of each day all will be beard by customers, the longer our technican stay, the more customers will pay. So, If you can prepare above things in advance, it will can help you save much time and money.