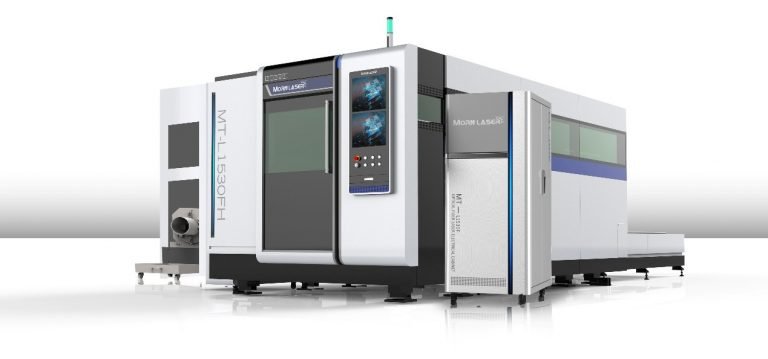

Do you work in an industry that requires a lot of engraving on metals and plastics? MORN’s fiber laser marking system will give you an advantage over other marking systems, and you will be impressed with the results. Our fiber laser marking machines will give you a solution to your marking or product tracking needs, and we are your source for high-precision marking and direct marking solutions. At MORN LASER, we understand the complexities involved in choosing the right industrial laser partner. We also have put together the following 4 tips to help get you started!

- What is a Laser?

Before knowing how to choose the right fiber laser engraving machine, let’s firstly figure out the definition of laser. LASER is an acronym for “Light Amplification by the Stimulated Emission of Radiation”. Lasers are one of mankind’s most important scientific developments and play a major role in our everyday lives. Lasers are used in almost any industry we can imagine including electronics, modern medicine, defense and more. In manufacturing, lasers are used everyday for: welding, cutting, drilling, cleaning, measuring, sensing, etching, marking, engraving and more. The laser has become one of our most powerful manufacturing tools! What makes fiber laser marking innovative is that it uses a metal-sheathed fiber cable which uses a high-power laser beam directly on the marking head. With 1064nm wavelength, fiber laser is the most common laser type utilized for industrial marking applications. All metals, most plastics and a variety of other substances can be processed with 1046nm wavelength.

- Fiber Laser Marking Safety

Lasers are organized into classes according to their characteristics. The standard for this classification system is IEC 60825-1. Our fiber laser metal engraving machine belongs to Class 4. A Class 4 laser is the highest and most dangerous class of lasers. Class 4 lasers can burn skin or cause permanent and serious eye damage. Hence proper safety precautions must be followed when working with Class 4 systems, such as wearing the proper safety eye-ware and avoiding the beam path. Class 4 systems are typically comprised of the laser marker components only, without any safety enclosure. The integrator of the laser will need to ensure proper safety precautions are followed when installing the laser system. And the laser beam is a vertical beam that won’t damage surrounding people. Even so, you could select an enclosed type of fiber laser marking machine if you are worried about laser damage.

- Understanding and Defining Your Applications Details

When qualifying your application, a few key details must be defined. These items are critical to make sure you receive the right fiber laser engraving system for your application.

- Throughput: How many parts are you planning to mark each day, week or year? This is an important detail to make sure your laser system can meet your production demands. The right laser system should include capabilities and ergonomic features which allow for maximum productivity.

- MarkingType: Modern fiber laser marking systems can create a variety of mark types, while the marking results achieved on your components can vary depending on material type as well as durability or post process requirements. General marking, deep marking or color marking will decide the fiber laser types you need to work with.

- Round Materials Marking: A fiber laser marking system can be configured with a rotary attachment which is used for laser engraving round objects, such as bottles, pens, golf clubs and so on.

- Evaluate your Potential Laser Partners!

With the availability of OEM and off the shelf components, the industrial laser market has seen a massive amount of growth with many new companies emerging yearly. It’s important to properly qualify your potential laser partner before purchasing a fiber laser metal marking machine. A few key items to review:

- Site Visit: Youshould always consider visiting your potential suppliers to evaluate their infrastructure and capabilities. At MORN, we welcome every customer to visit our factory and office at any time, testing our manufacturing process and working out a suitable laser solution for your business.

- Service and Support: Aftersales support is critical with industrial laser systems. From obtaining marking settings to learning new features and even unfortunate component failures, your partner should be available to support you at all times. Responsible after sales service and professional technical support are our commitment to each user.

- Right Fit System: Make sure the supplieris providing you with the best system at the right ROI for your application. Overcomplicated system purchases can drain your wallet and your resources. Your supplier should work with you in a consultative manner and therefore have your best interests in mind.

It doesn’t matter what metals you use in your industry, you can always find the most economical and efficient fiber laser marking system based on our cooperation. As choosing the right machine for the job will depend on your industry, our representatives would be happy to discuss that with you personally. No matter what your marking needs are, at MORN, our fiber laser machines are low maintenance, versatile and can work on various materials. Contact us today for more information on fiber laser marking.