Nowadays, the homogenization of products in the furniture market is serious. In this era of individuality, the mass production method is far from meeting the diversified needs of modern society. Due to the difficulty of metal processing, the price of metal furniture in the past is very expensive. Compared with the traditional processing method, the laser metal cutting machine can provide more types of furniture products at the same cost and the same output, realize the diversification and multi-functionality of the furniture products while ensuring the processing precision, and combine exquisite cutting and hollowing processes into the otherwise icy, cold metal material. The highly precise cutting of any contours in sheet metal parts, tubes, and profiles opens up new creative freedom for furniture manufacturers.

This post mainly talks about the advantages of metal furniture, benefits of laser metal cutting machines, as well as profitable markets that a laser metal cutting machine can bring to furniture fabricators. The outline is as below:

Table of Contents

Modern metal furniture: minimalist, stylish, durable

Metal furnishings are durable, stylish, and often ideal for the outdoors. They are also used to create different atmospheres in rooms, making the home-style more diverse and modern.

Modern metal furniture features unique style, folding function, rich color selection, considerable aesthetic value, good quality, and low price. In addition, metal furniture has the following advantages:

Moisture-proof, fire-resistant, antimagnetic

Metal furniture is moisture-proof, fire-resistant, antimagnetic. It is a good choice to store things. As long as the temperature is between 12 ° C and 14 ° C and the relative humidity is above 60 %, it is a paradise for mold breeding and a hotbed of rust. Precious paper documents, photos, instruments, valuable medicines, and various magnetic discs are possible to get wet. The moisture resistance of metal furniture can solve this trouble. Furthermore, in the event of an accident, it can survive the fire and minimize losses.

Environmental protection and durable

The raw materials for metal furniture are cold-rolled steel sheets, which are smelted and rolled from mineral resources. With the rise of the “green revolution” in the steel industry and the promotion of the “zero-energy” production process, the metal furniture products are recyclable, sustainable which will not produce waste for the society or have bad impact on the environment from the material selection to the production process and disuse.

More innovative, decorative and space-saving

Metal furniture creates a minimalist art in a casual style. The surface finish of metal furniture can be colorful polyurethane powder spray, or brilliant chrome plating, shining and elegant vacuum titanium nitride or titanium carbide coating, or the perfect combination of titanium plating and powder spraying. Currently, the fashion of gold plating and black gold plating has pushed the grade and taste of metal furniture to a higher level. Moreover, many kinds of metal furniture have fold function, it not only can use easily but also save space, making the living environment with limited relatively looser and more comfortable.

How can laser metal cutting machines benefit furniture fabricators?

In addition to being widely used in sheet metal processing, hardware cabinets, elevator processing, hotel metal products, and other high-tech industries, metal laser cutting machines are now applied to the furniture industry used by ordinary people. Lase metal cutting can bring benefits to furniture fabricators in the following aspects:

Incorporating exquisite cutting and hollowing processes into the icy metal furniture

Laser metal cutting combines exquisite cutting and hollowing processes into the icy, cold metal material. As a multifunctional tool, the laser metal cutter can process the most complex part geometries. Its strength also lies in its ability to cut various metals and thicknesses of sheet and tube. It can expand your product line or add new features or offerings to raise your sales and profits.

In addition, business opportunities are not solely based on the flexibility of the technology but also the potential for uniqueness from competitors. The creative design possibilities that laser metal cutting machines afford add a competitive edge to furniture fabricators.

Diversification

Nowadays, the homogenization of products in the furniture market is serious. In this era of individuality, the mass production method is far from meeting the diversified needs of modern society. However, compared with the traditional processing method, the laser cutting machine can provide more types of furniture products at the same cost and the same output, and realize the diversification and multi-functionality of the furniture products while ensuring the processing precision.

Quick ROI

The metal laser cutting machine brings you quick ROI. Ideally, laser metal cutting machines can recover costs in one year. With a little determination and effort, you are able to grow your business quickly. So, just start producing massive amounts of profit for your business with a metal laser cutting machine in no time.

Seize profitable market opportunities in the modern furniture industry with metal laser cutting machine

Now new opportunities have come to the fore, furniture fabricators who can grasp the trend of market demand will stand out.

In terms of market demand, the customized furniture fits well with the needs of consumers, and it not only utilizes the living space efficiently and reasonably, but also meets the aesthetic taste of young people with simple and smooth, modern sense, from space utilization, landscaping, and functional aspects.

From the production point of view, furniture fabricators should provide customized products according to the needs of consumers, on-demand production, reduce the cost of inventory storage and transportation, and ensure the stability of the capital chain.

A metal laser cutter is so versatile that it can fit well into a vast variety of markets. To offer you some insight, here are a few profitable markets you can tap into with a MORN LASER metal cutter.

1.Laser-cut safety box;

2.Laser-cut cabinet;

3.Laser-cut shelves;

4.Laser-cut beds;

5.Laser-cut office furniture;

6.Laser-cut school furniture;

Recommended metal furniture laser cutting machines

Metal furniture adopts metal pipes, plates or sticks as the main structure which combined with wood, various kinds of wood-based panels, glass, stone, etc., or iron furniture made entirely of metal materials.

Most of the metal furniture products require the processing of metal pipes and plates. Therefore, in order to meet the processing needs of the furniture market, MORN LASER has developed a laser sheet and tube cutting machine with different sizes for customers to choose freely. It meets the processing needs of tube cutting, sheet cutting as well as hollowing of metal sheet and tubes. It also enables furniture fabricators to maximize production efficiency, reduce costs, and find a new starting point for modern furniture design.

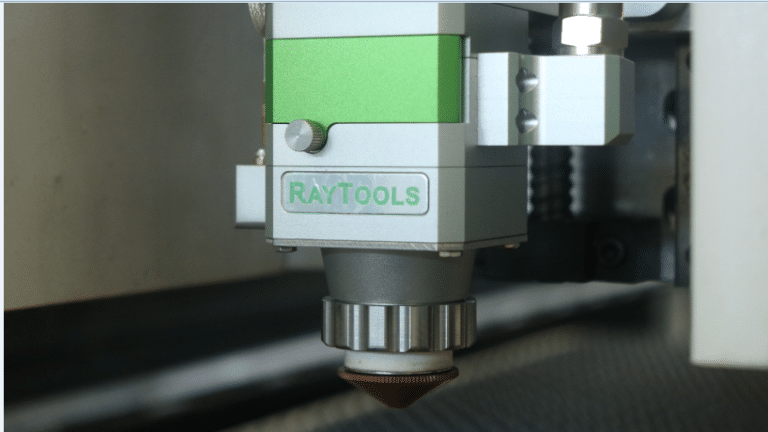

Sheet and tube laser cutting machine

MORN LASER Sheet and tube laser cutting machine is applicable to all kinds of metal pipes: round pipe, square pipe, rectangular pipe, elliptical pipe, waist pipe, D-shaped pipe, hexagonal pipe, irregular pipe, etc., as well as various sheets including stainless steel, mild steel, carbon steel, etc. It delivers a precise cut of arbitrary graphics, smooth cut without burr, and has automatic typesetting function and maximize material utilization, which solves various problems encountered in metal processing.

Metal furniture is in high demand all over the world. Tap into that market so you can offer your customers a broader range of products. Meanwhile, make sure you have the right partner on board to take that step, and MORN LASER fits the bill. Chat with our sales staff for a free sample cutting right away.