Compared to other guardrails, metal guardrail is more durable and reliable especially in outdoors. Metal guardrail laser cutting machine facilitates guardrail fabricators taking the lead in the competitive guardrail fabrication markets with unparalleled precision, speed and unique flexibility in pattern making. This post will briefly discuss the category and application of metal guardrails, advantages of metal laser cutting machine. You should also learn some knowledge about MORN LASER metal laser cutting machine, and most importantly how to improve your profit margin in the market. The outline is as below:

Table of Contents

Metal Guardrail: Our Most Reliable Safety Guardian

Guardrails, or railings, or protective guarding, may be one of the most overlooked things in everyday life. However, when you mention the “guardrail”, you will suddenly recall the scene passed by. It turns out that the guardrail has been silently guarding us all the time and can be seen everywhere in life.

Guardrails are a boundary to prevent access to dangerous or off-limits areas while allowing visibility in a greater way than a fence. Many public spaces are fitted with guardrails as a means of protection against accidental falls, or to protect pedestrians from roadside hazards or to guide vehicles back to the roadway and away from potentially hazardous situations.

When we choose the guardrail, metal guardrail will be the first priority for various dangerous places such as highways, construction sites, city streets, balconies, staircases, etc., thanks to its durability, firmness, corrosion resistance. It is our most reliable safeguard which can protect us to the highest extent.

Category and Application of Metal Guardrail

Metal guardrail refers to the general name of the guardrail made of metal material, including iron guardrail, zinc steel guardrail, stainless steel guardrail, cast iron guardrail, aluminum alloy guardrail, etc.

Stainless steel guardrail is most widely used in the field of guardrails due to their corrosion resistance and anti-rust performance.

The aluminum guardrail is now used by more and more customers, with the characteristics of convenient production and installation, variety and specifications, safety and environmental protection.

The cast iron guardrail is not smooth and relatively fragile compared with other metal guardrails.

Most of the wrought iron guardrails use 40MM wrought iron square tubes. The four corners of the square tube have uneven wavy patterns, and the produced guardrail products are more beautiful.

The Zinc steel guardrail is mainly made of galvanized pipe. Since the material itself is a zinc alloy material, the zinc steel guardrail does not need to be hot-dip galvanized. The production is also different from the wrought iron guardrail, the wrought iron guardrail is welded, and the zinc steel guardrail is mostly perforated, and some are welded links.

According to the use purposes, the guardrail can be divided into highway guardrails, street guardrails, municipal guardrails, landscape guardrails, stair railings, balcony guardrails, etc., which are widely used in villas, schools, hotels, entertainment venues, transportation, highways, etc.

Advantages of Metal Laser Cutting Machine in Metal Guardrail Fabrication

Laser cutting technology is a large-scale, high-efficiency, high-quality cutting production method for the metal guardrail. In the guardrail industry, it is often necessary to perform various forms of cutting, punching and welding on various square pipes or round pipes or flat sheets. In order to further increase the cutting and punching efficiency of metal pipes and sheets, improve the processing quality and reduce material waste, the metal laser cutting machine has become the “weapon” for all metal guardrail fabricators for the following advantages.

High precision

Metal laser cutting machine provides unparalleled precision for the production of metal guardrails that must be cut to high dimensional accuracy, because the laser light used does not have any physical presence and makes no contact with the material. It can also compensate for inaccuracies in the machining process such as metal deformation. The laser can be adjusted according to these deformations

High flexibility

Metal laser cutting machines can be used to process a wide range of metal such as carbon steel, stainless steel, aluminum, galvanized steel, alloy steel, etc. For graphics cutting, it can make almost any patterns and shapes on metal sheets and tubes. The shape of the template is designed by computer programming and can be quickly changed to provide customers with personalized processing. Even at the last minute, the operator can modify the design without affecting the production process of the entire product

High convenience

Metal laser cutting machine is easy to operate and user-friendly. Since laser cutting machines can be fully CNC controlled, they can repeatedly and consistently produce complex and intricate sheet and pipe guardrails to high tolerances.

Minimal distortion

The non-contact nature of the metal laser cutting machine decreases the risk of mechanical distortion, especially for flexible or thin materials, as well as decreases the risk of material contamination

Minimal heat affection

The Metal laser cutting machine offers minimal thermal input, with fine control over work area temperature.

Maximum material usage

The focused beam allows for narrower kerf widths. The smaller kerf minimizes the amount of material removed, thus more material utilization.

Fast and high adaptability

The speed of the metal laser cutting machine is also high. Its max. idle speed can reach 120m/min, which greatly improves the production efficiency of the guardrail fabrication.

Greater operator safety

Metal laser cutting machine decreases the risk of operator injury and provides quieter operations.

Recommended Metal Guardrail Laser Cutting Machine

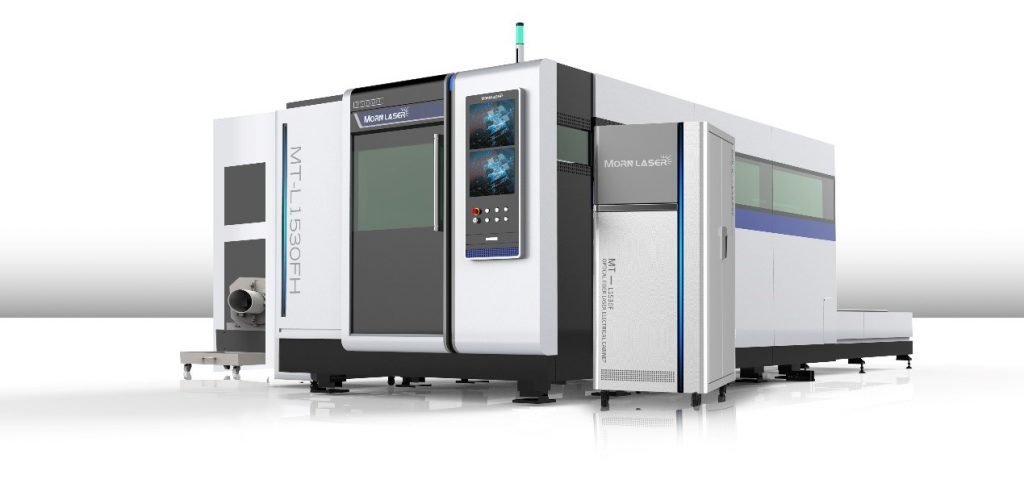

Recommended metal guardrail laser cutting machine

MORN LASER recommends you three types of metal guardrail laser cutting machines to meet different processing requirements: Sheet and tube laser cutting machine, all cover sheet and cutting fiber laser cutting machine and tube laser cutting machine. Among which, sheet and tube laser cutting machine, all cover sheet and cutting fiber laser cutting machine are dual-use which can both process sheets and pipes. If you have a limited budget, you can also have the tube laser cutting machine to process tube type guardrails. The pictures of them are as follows:

Sheet and tube laser cutting machine

Tube laser cutting machine

All cover sheet and cutting fiber laser cutting machine

Features of MORN LASER metal guardrail laser cutting machine

- Integrated square tube, round tube, flat tube, sheet cutting

- Japan imported gear rack transmission structure, excellent cutting performance, and stability;

- Self-centering fixture system to ensure a stable pipe conveying process, thus ensuring high-precision, high-quality processed products;

- accurate processing size, which can replace many traditional processing equipment such as sawing, punching, etc.;

- The saddle-shaped pipe support frame ensures the pipe will not be deformed during processing.

Videos of metal guardrail laser cutting machine

Laser cutting stainless steel sheet

Lase cutting tube

Require customized solutions for your guardrail fabrication

MORN LASER provides customized solutions for guardrail fabrication. Welcome to talk to our professional sales online or send emails to let us know your processing requirements, or just to gain sights for your business. You can also visit our product pages for more details of the machine.