The safety and quality of food machinery have a direct influence on people’s health and food safety. Food production nowadays is progressed on the way of mechanization, automation, professionalization and scale expansion, aiming to promote wholesomeness, safety and production efficiency. In the course of improving food safety, food machinery safety is an essential chain that decides whether people have access to healthy and safe food. Hopefully, food machinery made by fiber laser cutting machine can build the first line of defense.

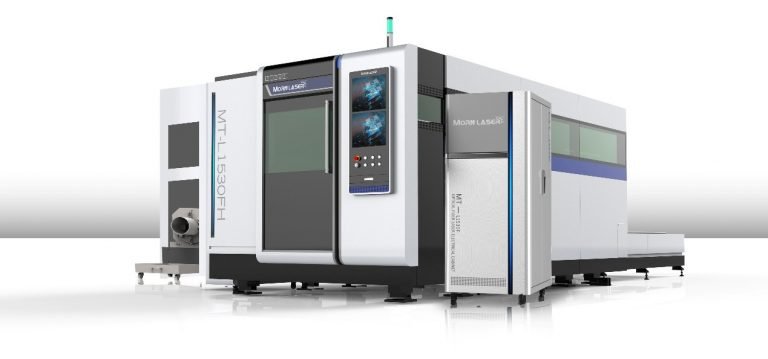

Fiber laser cutting machine outweighs traditional production methods for food machinery manufacturing industry in that traditional ones require open mold, stamping, shearing plates and bending process, consuming more molds with lower efficiency and more cost. While fiber laser cutting technology boasts the following 7 advantages.

1.Safe and clean

During the cutting process, fiber laser cutter doesn’t touch the surface of materials directly so that it can keep the safety and wholesomeness of food machinery.

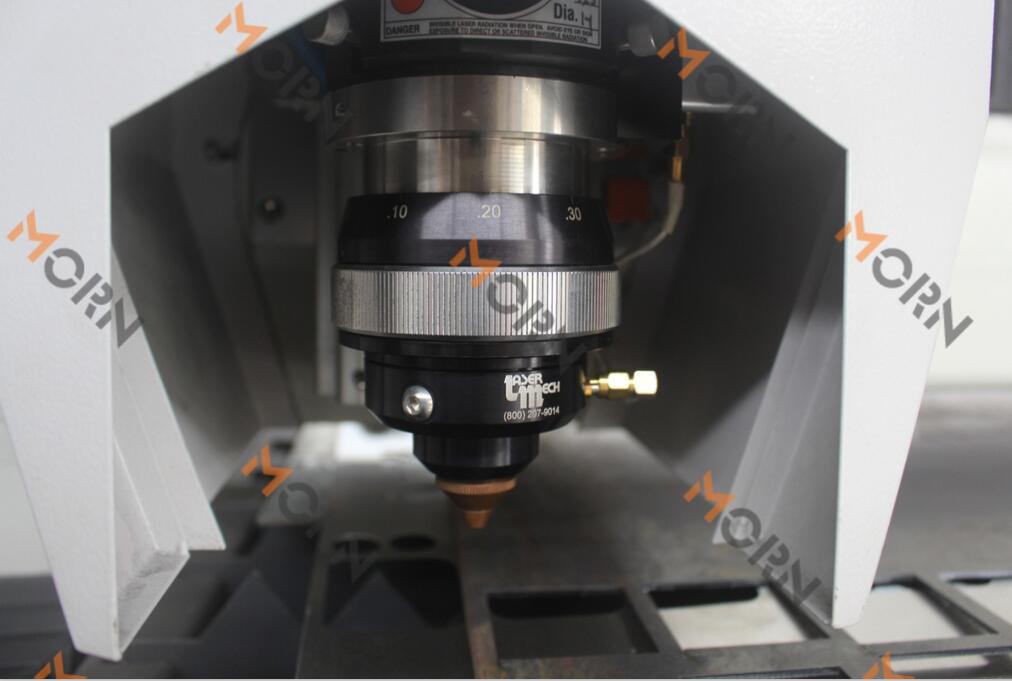

2.High precision

Fiber laser cutting machine can cut with high precise cutting edge of 0.1~0.2mm.

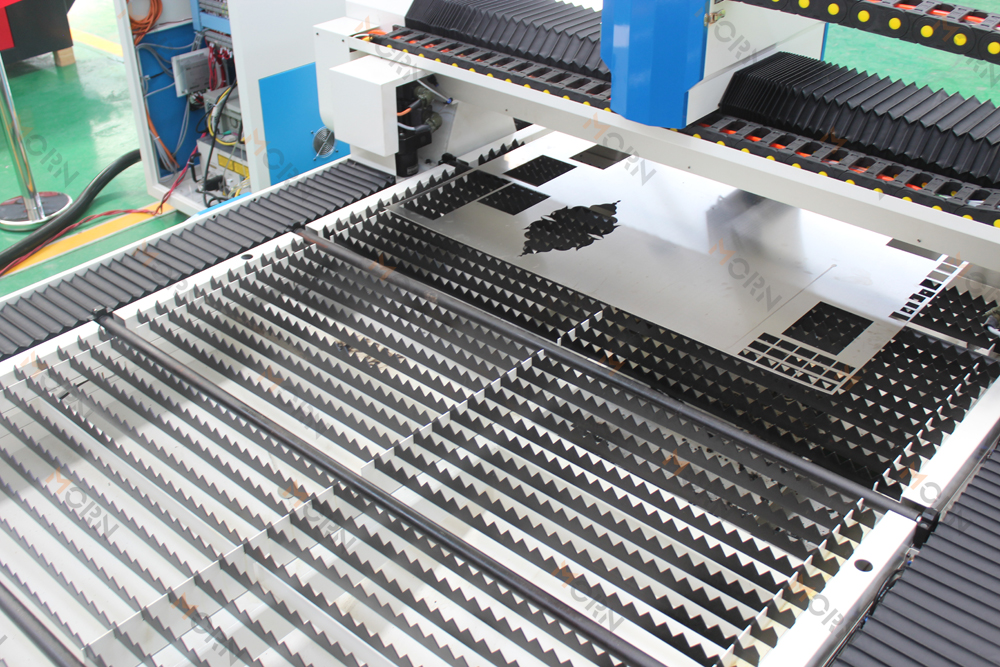

3.Smooth cutting edge

No rags exist in fiber laser cutting edge which is also so smooth that no secondary processing is required to produce high-end food machinery.

4.Fast cutting speed

Fiber laser metal cutting machine cuts at a fast speed, which effectively improves the production efficiency of food machinery production.

5.Suitable for processing large-size materials

Molds of large-size product is made at pretty high expenditure, while fiber laser cutting technology needs no molds and meantime can avoid the deformation of materials. This can greatly reduce the production cost and enhance the quality and grade of food machinery.

6.Saving materials and cost

Computer programming is applied by fiber laser cutter to increase the utilization efficiency of materials to the utmost extent, in which way, lots of materials and cost can be saved.

7.Suitable for developing new products

Once the product design drawings are formed, laser production process can be conducted immediately. Therefore new types of food machinery can be produced in this way.