Comparing with CO2 laser marking machines or YAG laser marking machines, fiber laser marking machines are now taking the leading role in laser marking technologies. In other words, fiber laser marking system represents the ultimate laser marking technologies due to its extremely compact function and structure.

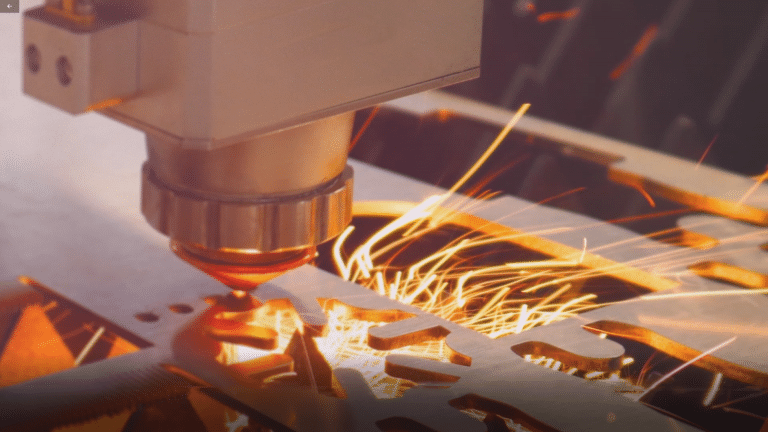

The main work principle of the fiber laser marking machine is that the fiber laser beam marks on the surface of different materials including metals and some non-metals in the forms of various patterns, logos or some other tags. These marks are permanent and won’t disappear with time going by. Therefore metals or non-metals can carry cultural connotation of products, companies, or special symbols to wider range of population and places, which marks not only patterns or characters but culture and value.

With such advantageous technique, fiber laser marking machines can be used in a range of industries, such as auto parts, electronic components, mechanical parts, instruments, hardware tools, articles for daily use, etc. And in the real marking process, the greater the power is, the faster and deeper the marking is. Generally, taking our fiber laser marking machine as an example, a 50W/100W machine can be utilized to mark on the sheet metals thinner than 1mm. The common marking depth is no more than 0.01mm, and if you persists marking in 0.1mm deep, a deeper fiber laser marking machine will be recommended. As for the marking speed, high-speed lens tends to marking at a faster speed, up to 7000mm/s; a common lens can marking at 2000mm/s to a maximum.

In addition, the fiber laser generator of our fiber laser marking machine has a very long lifespan that can work up to 100,000 hours, which will yield fat economic returns for you. If you are longing for further information about fiber laser machines, please feel free to contact us.