Acting as the mainstream cutting solutions, fiber laser and CO2 laser both take up a great place in the modern laser industry. But if you dive into laser machines, you will find differences between these two technologies.

Which laser type for which application?

Fiber Laser

Highlights

- Speed – Faster than CO2 lasers in thin materials as the laser can be absorbed quickly with a slight lead in speed when cutting with Nitrogen (fusion cutting).

- Cost per part – less than the CO2 laser depending on sheet thickness.

- Safety – Strict safety precautions must be taken (the machine is completely enclosed) as the laser light (1µm) can pass through very narrow openings in the machine’s frame causing irreparable damage to the eye’s retina.

- Beam guidance – fiber optics.

CO2 Laser

Highlights

- Quality – Quality is consistent throughout all thicknesses of material.

- Flexibility – high, suitable for all material thicknesses.

- Safety – CO2 laser light (10µm) is better absorbed by the machine frame, which lowers the risk of irreparable damage to the retina. Personnel should not look directly at the cutting process through the acrylic panel in the door as the bright plasma also presents a risk to sight over a period of time. (Similar to looking at the sun.)

- Beam guidance – mirror optics.

- Cutting with Oxygen (flame cutting) – there is no difference in quality or speed shown between the two types of lasers.

Also, let’s learn some advantages that make fiber laser machines stand out.

1. Fiber laser is delivered through a laser optic cable instead of mirrors and channel used by CO2 laser cutting machine, reducing power loss and increasing energy efficiency. So production cost can be lowered directly.

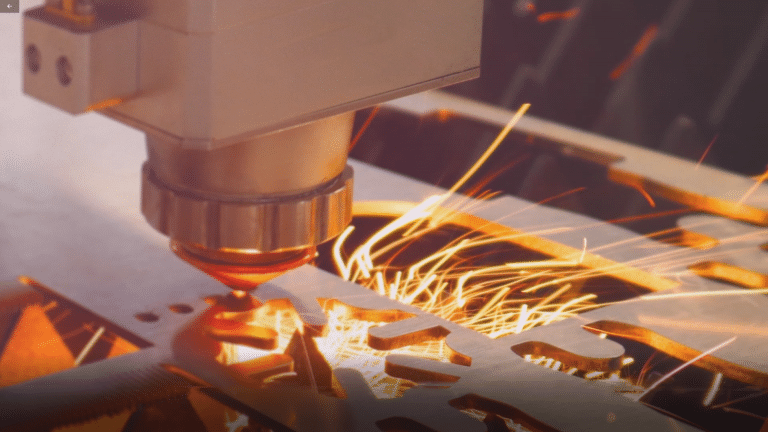

2. The fiber laser wavelength is ten times shorter than that of the CO2 laser. The more focused laser beam will be produced to interact with different metals.

3. Fiber laser machines can have dual interchangeable platforms where materials and finished cutting sheets can load or unload automatically to reduce boring repetitive work and save much time.

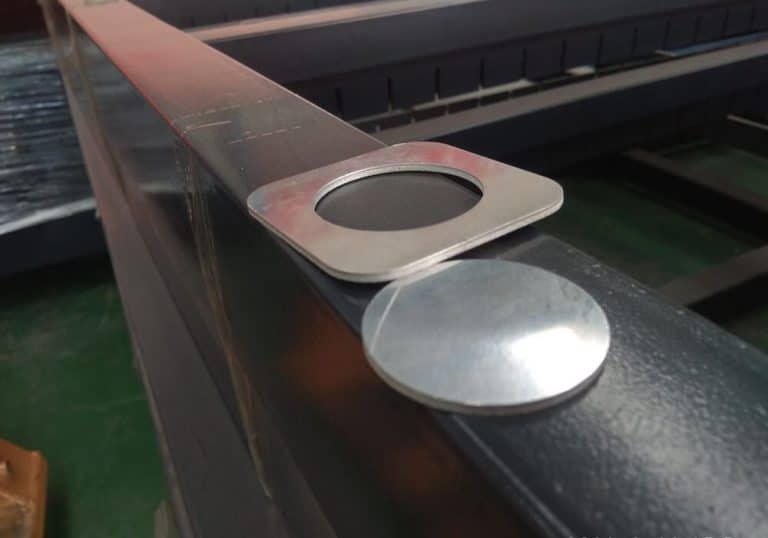

4. As sheet metals are more popular in manufacturing industries, sheet metals processing has played an increasingly important part in the various metal business. Fiber laser machines can perfectly cater to this need, while CO2 laser machines are more suitable for thick plates cutting.

5. Maintenance is also an essential part for machines. And little maintenance and devices replacement are required for a fiber laser machine, saving worry and money. Contrarily, a CO2 laser machine needs regular and annual maintenance with components replacement, which can cost you more than ten thousand a year.

6. Fiber laser metal cutting machine performs with higher cutting precision and perfect cutting edge, for the tons of cutting table ensures the stability in the whole cutting process and the gas will blow away the residue produced from cutting materials.

7. Advantages of fiber laser technology have attracted continuous investment and attention from industry experts, researcher and investors, then a huge development potential exists in fiber laser field.

These introductions can not decide your laser business, but if you want to refresh your laser cutting business or upgrade your laser machines, we are willing to provide you with customized solutions. And for more details, you can also look for more posts under this blog.